VLT

®

FCM Series

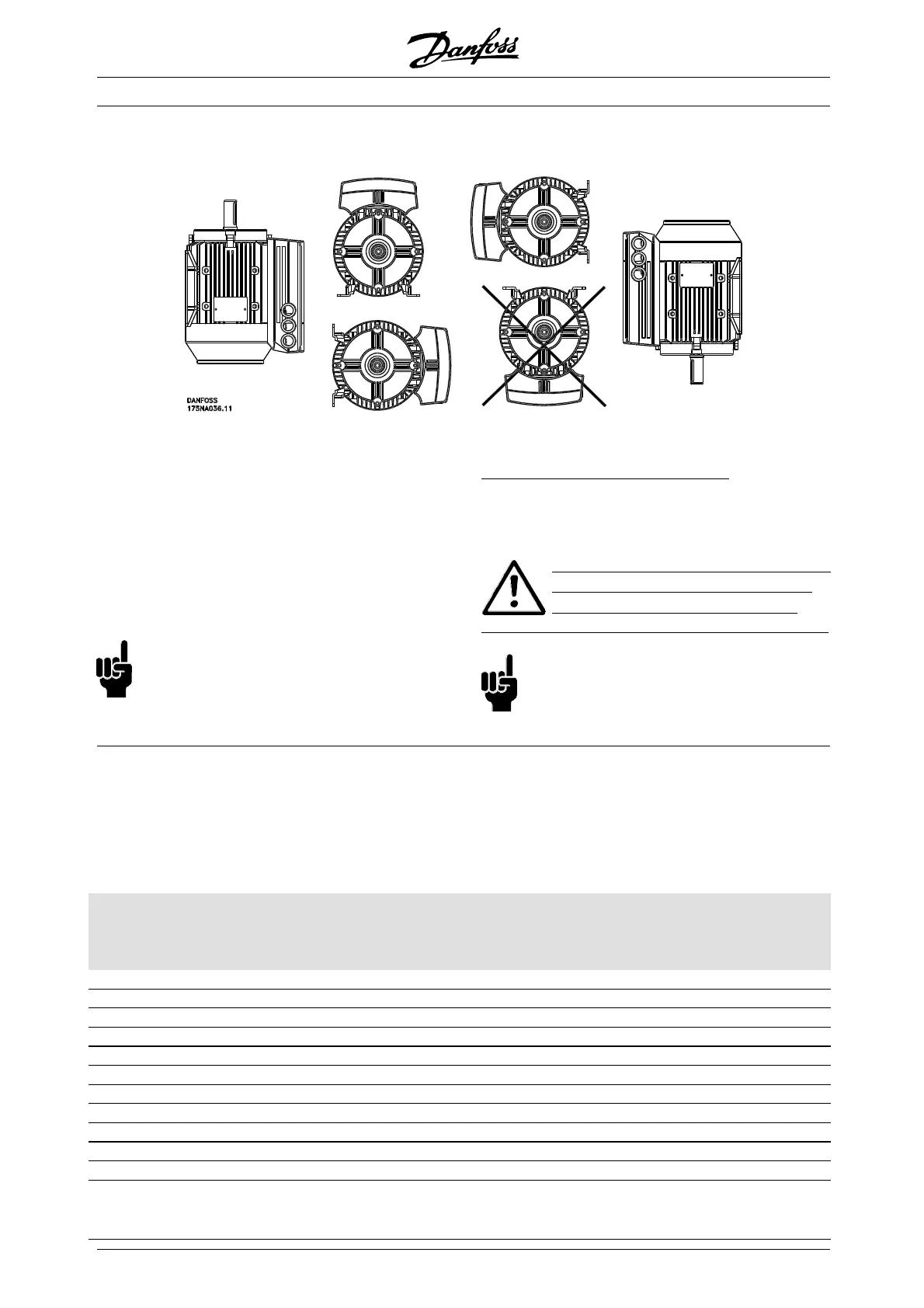

■ Installation of the FC motor

FC motors must be installed with adequate access for

routine maintenance. A minimum of 0.75m of working

space around the motor is recommended. Adequate

space around the motor, particularly at the fan inlet

(50 mm), is also necessary to facilitate airflow.

Where several FC motors are installed in close

proximity, care must be taken to ensure that there is

no recirculation of exhausted warm air. Foundations

must be solid, rigid and level.

NB!:

Electrical installation

Do not remove the top foil inside the inverter part,

as this is a part of the protective arrangements.

F

itting pinions, pulleys and couplings.

These should be bored to our standard limits and fitted

on the shaft with a screwing motion. Attention must

be paid to correct guarding of all moving parts.

Tapping of fitments onto the FC motor shaft,

with a hammer or mallet, causes bearing

damage. This results in an increase in

bearing noise and a significant reduction in bearing life.

NB!:

Max. length of mounting bolts penetrating

the B14 flange, see section Dimensions

in this chapter.

■ Alignment

When the application calls for direct coupling, the

shafts must be correctly aligned in all three planes. Bad

alignment can be a major source of noise and vibration.

Allowance must be made for shaft endfloat and

thermal expansion in both axial and vertical planes.

It is preferable to use flexible drive couplings.

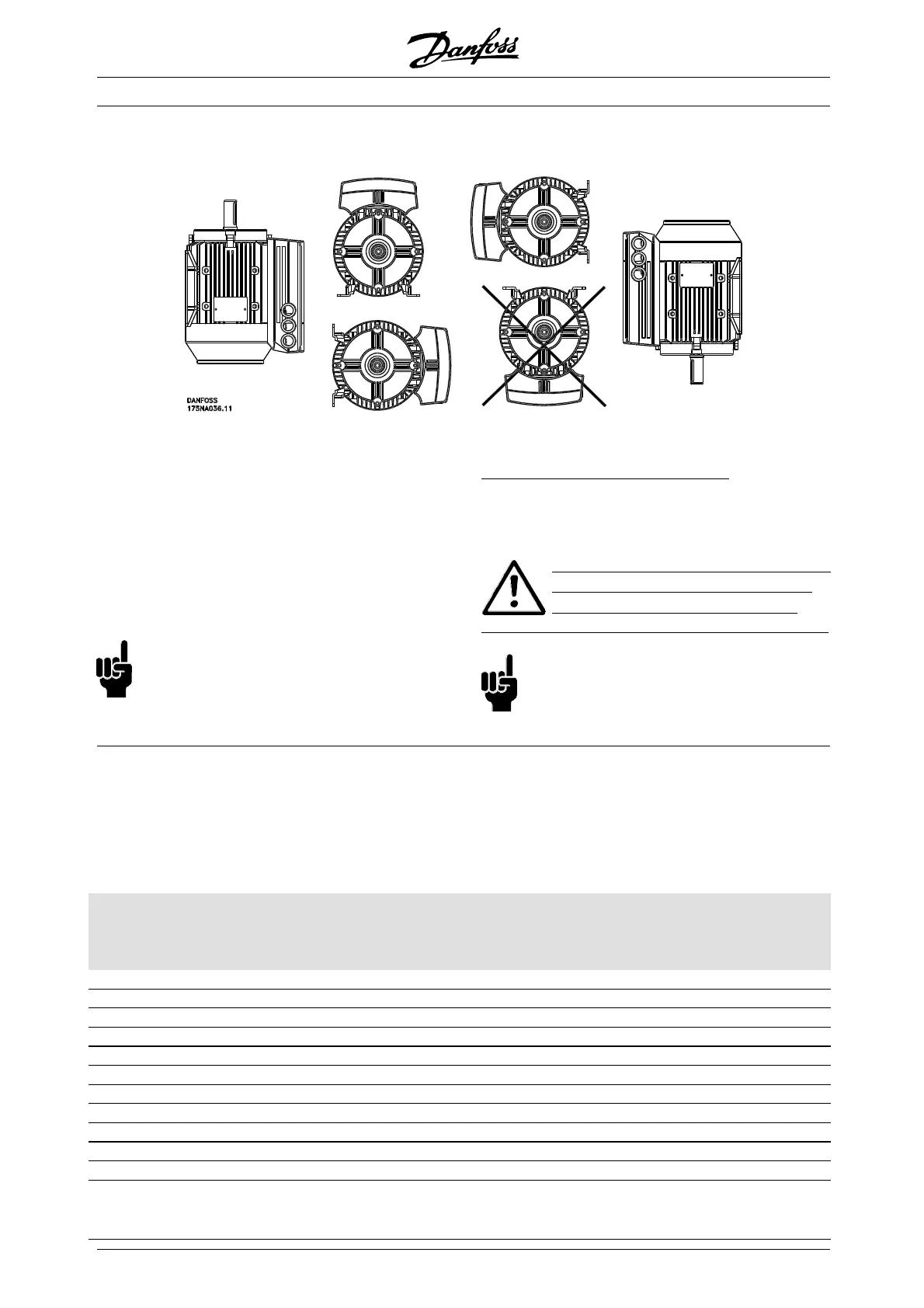

Maximum permissible external axial and radial loads in N

1

- standard ball bearings

Horizontal shaft Vertical shaft

Load towards Load away Shaft up Shaft down

Frame motor from motor load load load load

size Poles Up Down Up Down Max. radial

2

80 2 275 441 481 245 294 432 638

4 373 549 569 343 392 520 785

90 2 412 638 598 294 373 520 824

4 540 765 716 402 471 628 903

100 2 853 853 932 932 814 814 1207

4 1010 1010 1118 1118 961 961 1393

112 2 853 853 932 932 814 814 1207

4 1010 1010 1118 1118 961 961 1393

132S 2 1059 1403 1570 952 1216 1305 1785

4 1265 1609 1825 1138 1472 1481 1972

132M 4 1256 1609 1854 1109 1501 1462 2040

1

All figures are based on Lna bearing life of 20,000 hours.

Lna = adjusted L10 life rating taking account of:-Reliability -Material improvements -Lubrication conditions

2

Max. permissible radial load at end of shaft (horizontal mounting).

MG.03.H3.02 - VLT is a registered Danfoss trademark

20

Loading...

Loading...