Enter line to common stator winding resistance

(Rs). If only line-line data is available, divide the

line-line value by 2 to achieve the line to

common (starpoint) value.

It is also possible to measure the value with an

ohmmeter, which also takes the resistance of the

cable into account. Divide the measured value by

2 and enter the result.

6. Parameter 1-37 d-axis Inductance (Ld).

Enter line to common direct axis inductance of

the PM motor.

If only line-line data is available, divide the line-

line value with 2 to achieve the line-common

(starpoint) value.

It is also possible to measure the value with an

inductance meter, which also takes the

inductance of the cable into account. Divide the

measured value by 2 and enter the result.

7. Parameter 1-40 Back EMF at 1000 RPM.

Enter line-to-line back EMF of PM motor at 1000

RPM mechanical speed (RMS value). Back EMF is

the voltage generated by a PM motor when no

adjustable frequency drive is connected and the

shaft is turned externally. Back EMF is normally

specied for nominal motor speed or for 1000

RPM measured between two lines. If the value is

not available for a motor speed of 1000 RPM,

calculate the correct value as follows: For

example, if back EMF at 1800 RPM is 320 V, the

back EMF at 1000 RPM is:

Back EMF=(Voltage/

RPM)x1000=(320/1800)x1000=178.

Program this value for parameter 1-40 Back EMF at

1000 RPM.

Test motor operation

1. Start the motor at low speed (100–200 RPM). If

the motor does not turn, check installation,

general programming and motor data.

Parking

This function is the recommended choice for applications

where the motor is rotating at slow speed (for example,

windmilling in fan applications). Parameter 2-06 Parking

Current and parameter 2-07 Parking Time are adjustable.

Increase the factory setting of these parameters for

applications with high inertia.

Start the motor at nominal speed. If the application does

not run well, check the VVC

+

PM settings. Table 5.13 shows

recommendations in dierent applications.

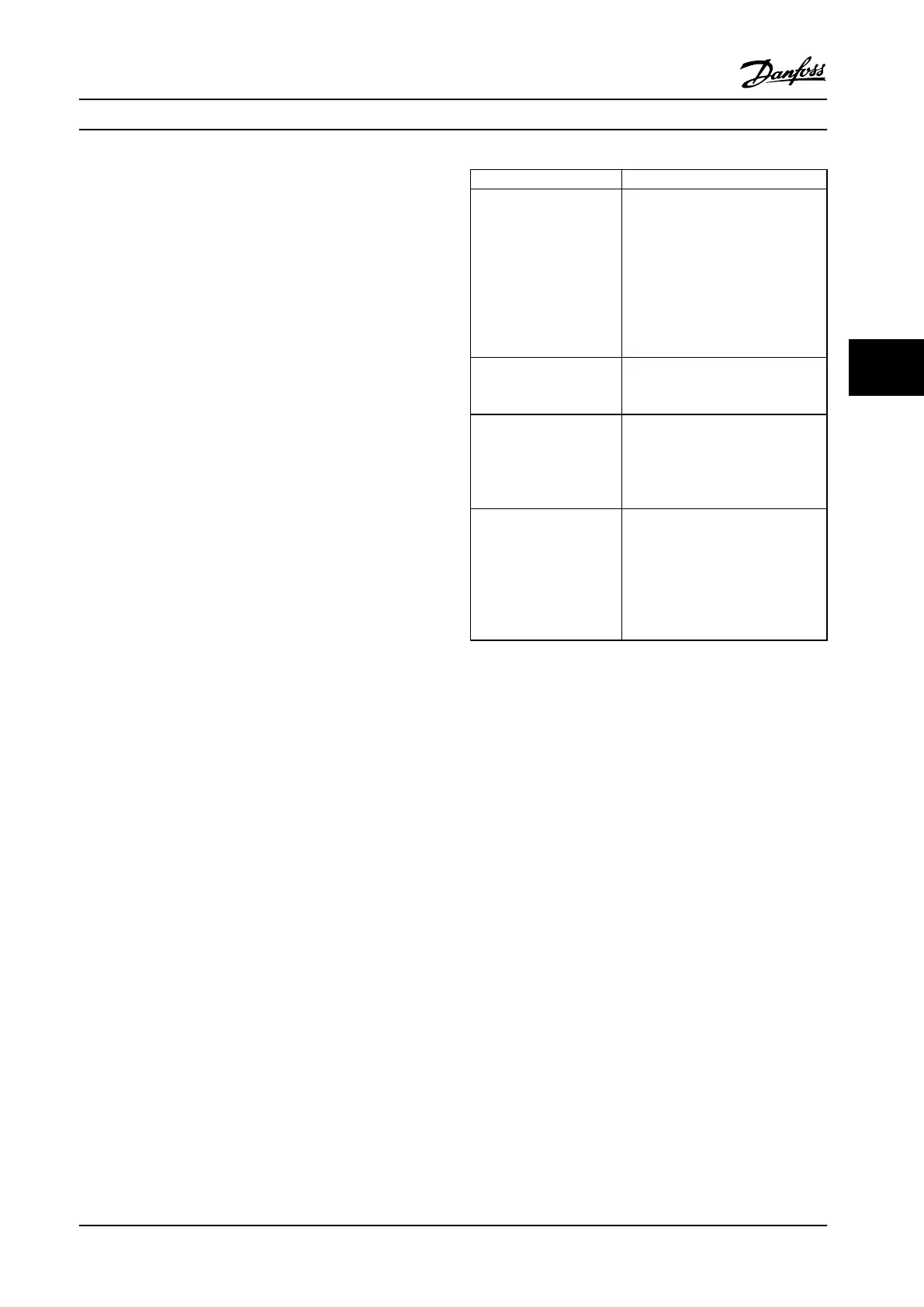

Application Settings

Low inertia applications

I

Load

/I

Motor

<5

•

Increase the value for

parameter 1-17 Voltage lter time

const. by factor 5–10.

•

Reduce the value for

parameter 1-14 Damping Gain.

•

Reduce the value (<100%) for

parameter 1-66 Min. Current at

Low Speed.

Medium inertia

applications

50>I

Load

/I

Motor

>5

Keep calculated values.

High inertia applications

I

Load

/I

Motor

> 50

Increase the values for

parameter 1-14 Damping Gain,

parameter 1-15 Low Speed Filter Time

Const. and parameter 1-16 High

Speed Filter Time Const.

High load at low speed

<30% (rated speed)

Increase the value for

parameter 1-17 Voltage lter time

const.

Increase the value for

parameter 1-66 Min. Current at Low

Speed (>100% for longer time can

overheat the motor).

Table 5.13 Recommendations for Dierent Applications

If the motor starts oscillating at a certain speed, increase

parameter 1-14 Damping Gain. Increase the value in small

steps.

Starting torque can be adjusted in parameter 1-66 Min.

Current at Low Speed. 100% provides nominal torque as

starting torque.

5.4.3 Automatic Motor Adaptation (AMA)

Automatic motor adaptation (AMA)

It is highly recommended to run AMA, because it measures

the electrical characteristics of the motor to optimize

compatibility between the adjustable frequency drive and

the motor under VVC

+

mode.

•

The adjustable frequency drive builds a

mathematical model of the motor for regulating

output motor current, thus enhancing motor

performance.

•

Some motors may be unable to run the complete

version of the test. In that case, select [2] Enable

reduced AMA in parameter 1-29 Automatic Motor

Adaption (AMA).

•

If warnings or alarms occur, see chapter 8.4 List of

Warnings and Alarms.

Commissioning Instruction Manual

MG07A122 Danfoss A/S © 11/2015 All rights reserved. 29

5 5

Loading...

Loading...