Maintenance and Adjustments

2-2

2.1.1 Cleaning the Printhead

If print quality declines (symptoms can include non-compliant bar codes, print dropouts, streaks,

etc.), the typical cause is debris buildup on the Printhead. If not removed, this buildup can lead to

element failure, reducing the service life of the Printhead. Depending upon the media, ribbon, and

printing parameters used, different methods and supplies are recommended to clean the Printhead.

CAUTION

NEVER use a sharp object on the Printhead; damage can result.

Faulty Label:

Streaks (e.g., white lines) in the direction of print can indicate a dirty or

faulty Printhead.

2.1.1.1 Cotton Swab Procedure

This procedure is recommended when using direct thermal media, or thermal transfer media with wax

ribbon.

1. Stop printing. Allow the Printhead to cool.

2. Raise the Printhead Assembly then remove media and ribbon from the printer.

3. Turn OFF and unplug the printer. Using a Cotton Swab moistened (not soaked) with isopropyl

alcohol, gently wipe the entire Printhead surface clean, while paying special attention to the Burn

Line to ensure all buildup is removed. Allow the Printhead to dry.

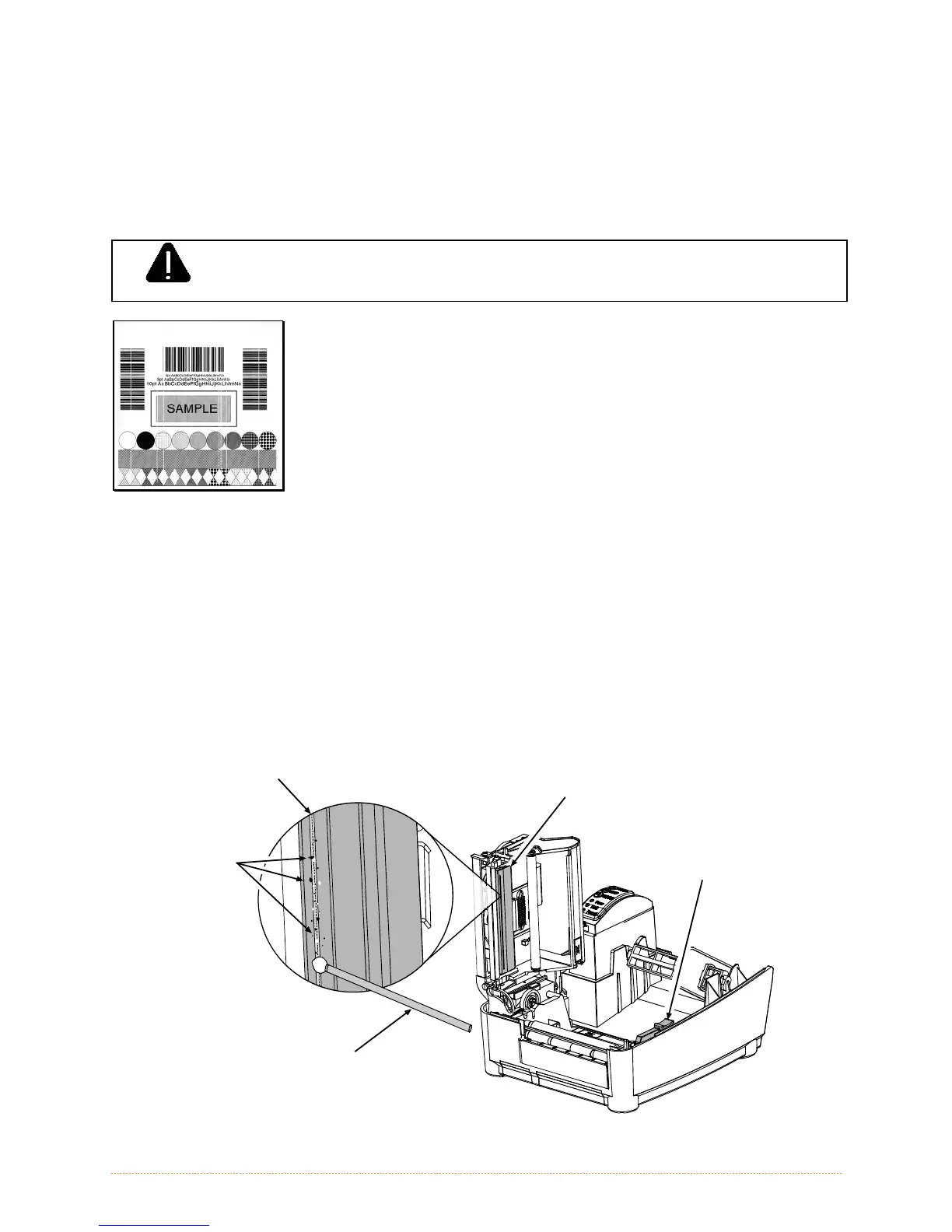

Cotton Swab

Burn Line

buildup

Printhead

Latch

Printhead

Loading...

Loading...