10

Fig. 17

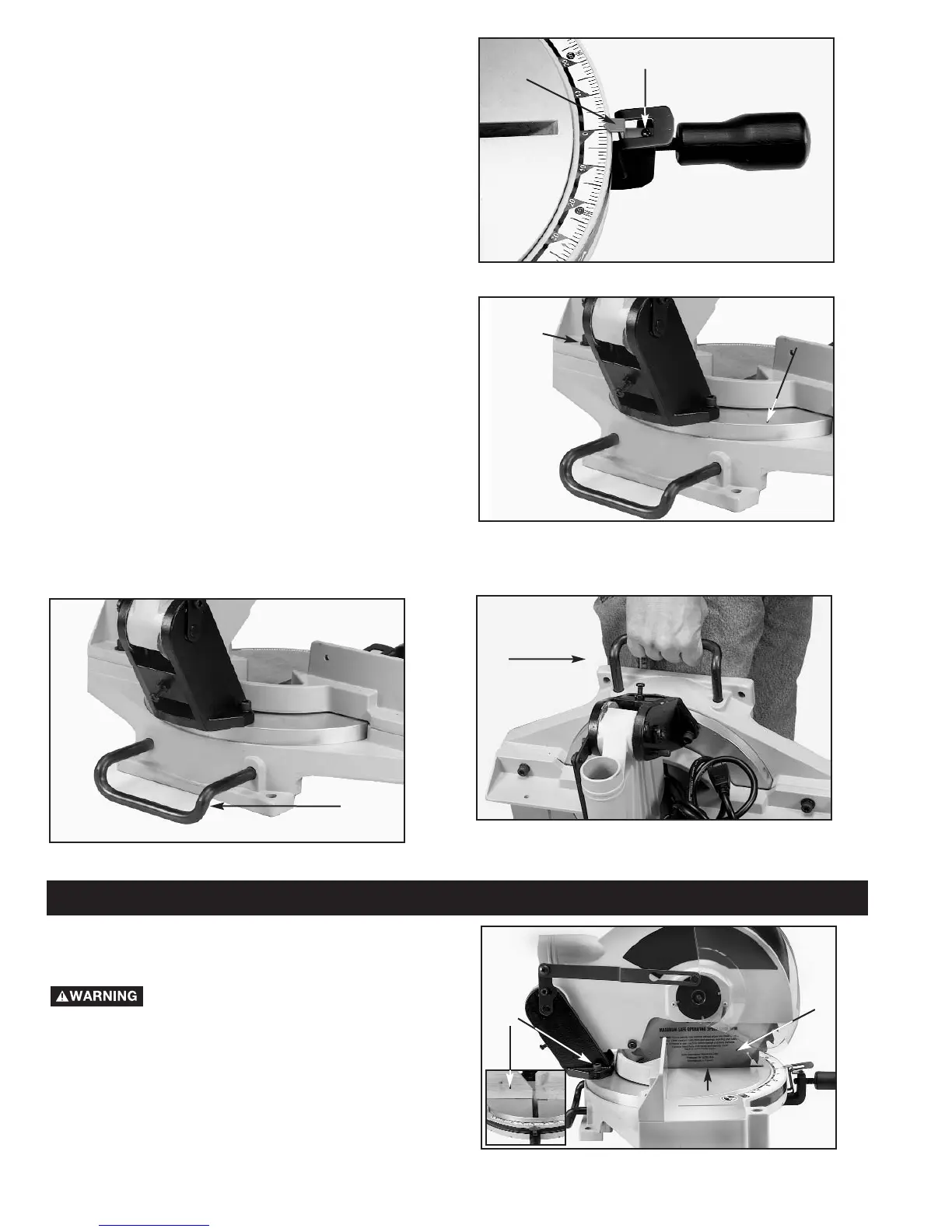

ADJUSTING BLADE PARALLEL TO

TABLE SLOT

1. Lower the cutterhead and check to see if the saw

blade (A) Fig. 18 is parallel to the left edge (B) of the

table opening.

2. If an adjustment is necessary, loosen two screws,

one of which is shown at (C) Fig. 18, and move the

cutterhead until the blade (A) is parallel with the left

edge (B) of the table opening. Tighten two screws

(C).

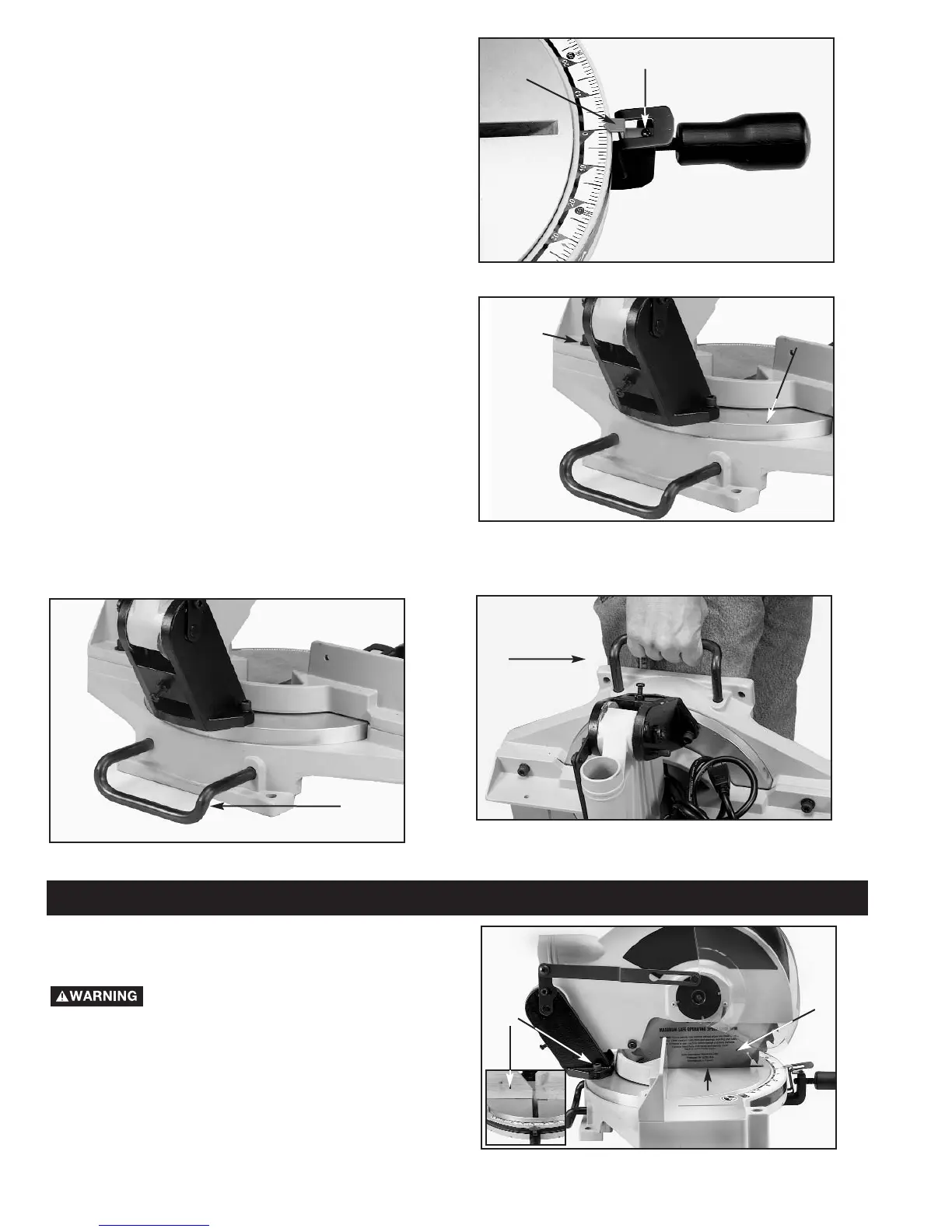

ADJUSTING POINTER

If it becomes necessary to adjust the pointer (A) Fig. 14,

loosen screw (B), adjust the pointer and tighten screw

(B).

Fig. 14

A

B

Fig. 15

Fig. 16

A

A

B

REAR SUPPORT/CARRYING

HANDLE

A rear support bar (A) Fig. 16 is provided to prevent the

miter saw from tipping to the rear when the cutterhead

is returned to the up position. For maximum support,

the bar (A) should be pulled out as far as possible.

The support bar (A) Figs. 16 and 17 can also be used as

a carrying handle.

LOCKING CUTTERHEAD IN THE

DOWN POSITION

When transporting the miter saw, the cutterhead should

always be locked in the down position. Lower the

cutting arm (A) Fig. 15, and push in plunger (B) until

other end of plunger (B) engages with hole in cutting

arm.

IMPORTANT: Carrying the machine by the switch

handle will cause misalignment. Always lift the machine

by the base or rear support/carrying handle (A) Fig. 16

and 17.

Fig. 18

A

C

B

A

ADJUSTMENTS

Disconnect machine from power source.

Loading...

Loading...