Chapter 12 Description of Parameter SettingsME300

12.1-09-8

Unsigned int crc_chk(unsigned char* data, unsigned char length)

{

int j;

unsigned int reg_crc=0Xffff;

while(length--){

reg_crc ^= *data++;

for(j=0;j<8;j++){

if(reg_crc & 0x01){ /* LSB(b0)=1 */

reg_crc=(reg_crc>>1) ^ 0Xa001;

}else{

reg_crc=reg_crc >>1;

}

}

}

return reg_crc; // return register CRC

}

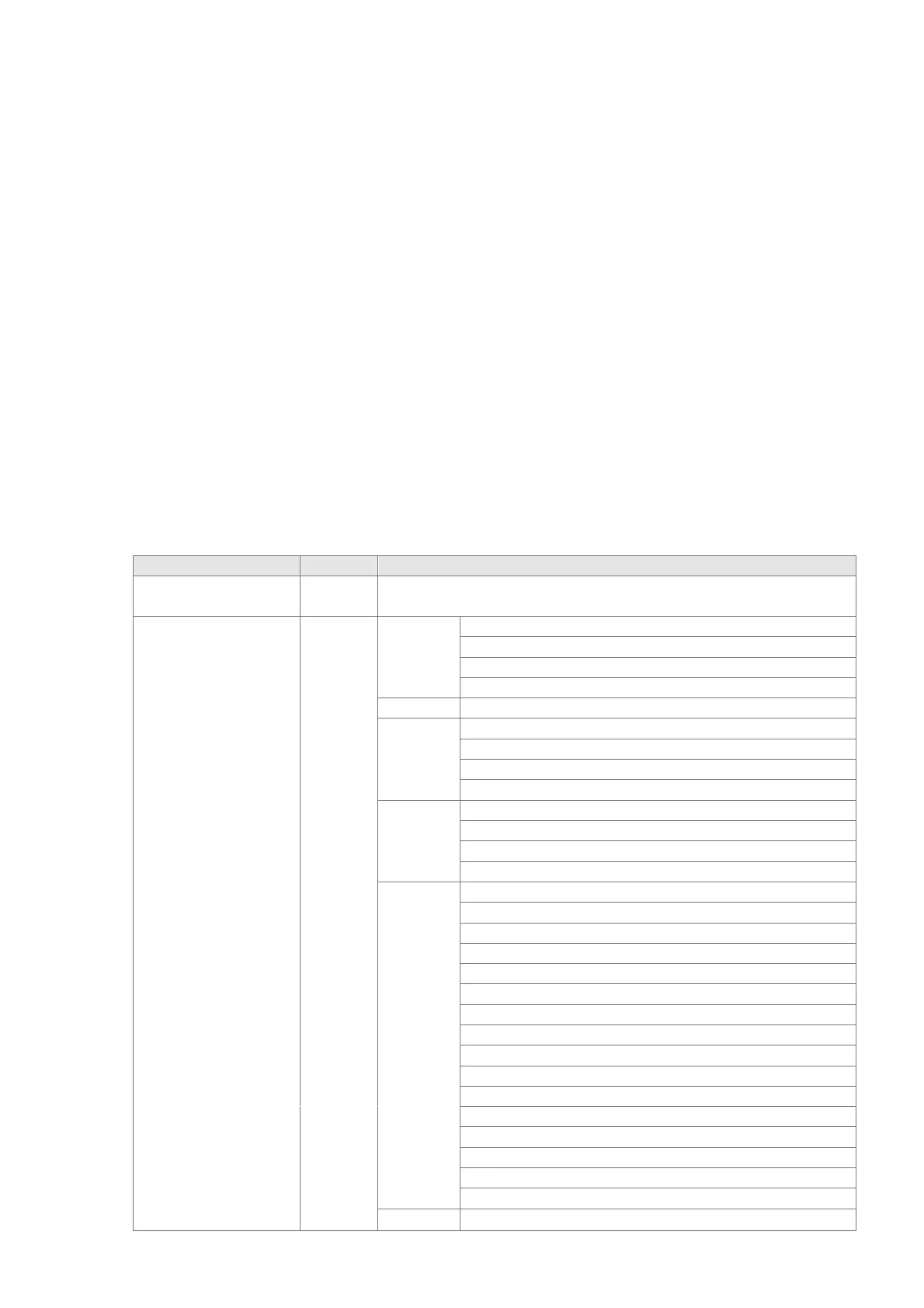

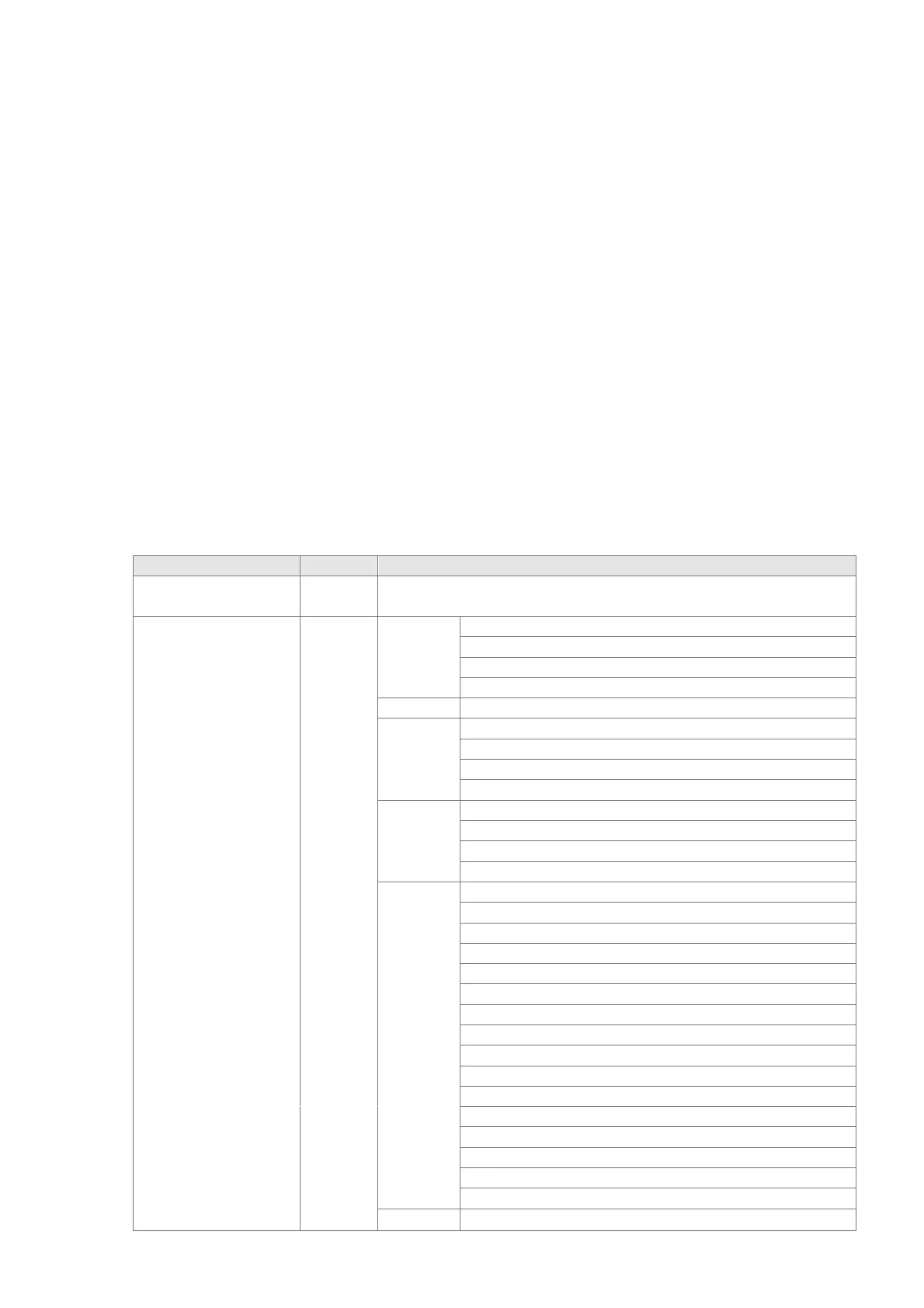

4. Address list

Content Register Function

AC motor drive

parameters

GGnnH

GG is the parameter group, nn is the parameter number; for

example, the address of Pr.04-10 is 040AH.

Command write only 2000H bit 1–0 00B: No function

01B: Stop

10B: Run

11B: JOG + RUN

bit 3–2 Reserved

bit 5–4 00B: No function

01B: FWD

10B: REV

11B: Change direction

bit 7–6 00B: 1

st

acceleration / deceleration

01B: 2

nd

acceleration / deceleration

10B: 3

rd

acceleration / deceleration

11B: 4

th

acceleration / deceleration

bit 11–8 000B: Master speed

0001B: 1

st

Step speed frequency

0010B: 2

nd

Step speed frequency

0011B: 3

rd

Step speed frequency

0100B: 4

th

Step speed frequency

0101B: 5

th

Step speed frequency

0110B: 6

th

Step speed frequency

0111B: 7

th

Step speed frequency

1000B: 8

th

Step speed frequency

1001B: 9

th

Step speed frequency

1010B: 10

th

Step speed frequency

1011B: 11

th

Step speed frequency

1100B: 12

th

Step speed frequency

1101B: 13

th

Step speed frequency

1110B: 14

th

Step speed frequency

1111B: 15

th

Step speed frequency

bit 12

1: Enable bit 06

–11 function

Loading...

Loading...