– 13 –

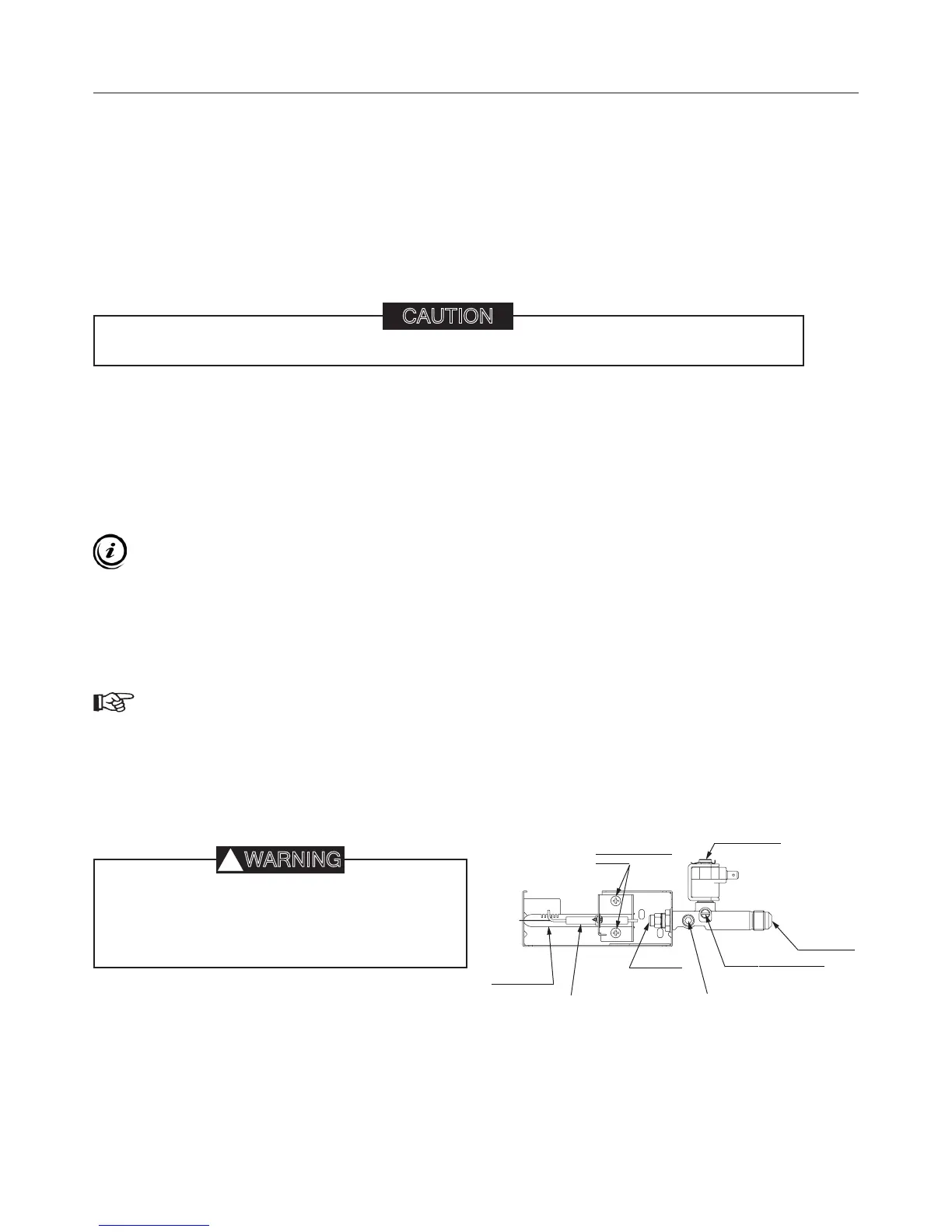

CHECKING THE LP GAS PRESSURE

The LP gas pressure should be checked and the main regulator

readjusted if pressure is incorrect. The correct operating pres-

sure is 11 inches of water column. Measure the LP gas pressure

at the test port, just ahead of the burner jet.

PERIODIC MAINTENANCE

CHECKING THE CONNECTIONS

Check all connections in the LP gas system (at the

back of the refrigerator) for gas leaks. The LP gas

supply must be turned on.

Apply a non-corrosive bubble solution to all LP gas

connections. The appearance of bubbles indicates a

leak and should be repaired immediately by a quali-

fied serviceman.

1.

2.

MAINTENANCE & SERVICE

Always keep the food compartment and the freezer clean.

If the refrigerator will not be in operation for a period of weeks it should be emptied, defrosted, cleaned and the doors left ajar,

see STORAGE PROCEDURE / WINTER OPERATION.

Periodic inspection, cleaning and maintenance of the refrigerator is recommended.

Make sure the area behind the refrigerator is clear and free from combustible material, gasoline and other flammable

vapors or liquids.

Dust off the coils on the back of the refrigerator (use a soft brisled brush).

Make sure the upper and lower vents are free from any obstructions.

NDA1402

Check the burner flame for proper appearance. The flame should be light blue.

A qualified service technician should, at least once a year, inspect the connections, the control system, the LP gas pressure

and the flue baffle, see PERIODIC MAINTENANCE.

•

•

•

-

-

-

•

•

If your refrigerator stops cooling, immediately turn the refrigerator off and see a Dometic dealer.

EXPLOSION HAZARD. Never use an open

flame to check for gas leaks. Failure to heed this

warning could cause an explosion resulting in

death or severe personal injury.

Loading...

Loading...