SROXG Touch Screen.doc 02-2020

INSTALLATION

Take off the packaging material with care. Take off all the material used for packing and accessories.

Seal the unit on the floor with silicone. Verify every adjustments and correct it if necessary. Install the

hood covering the top front of the oven.

Each unit is set up to be used with the type of gas and electrical supply specified on the nameplate fixed

on the oven.

The installation must be conform with National fuel gas code ANSI Z223.1-XX and CAN/CGA-

B149-XX, Gas installation Code and local Codes where applicable. Refer to last edition year for XX.

The oven's combustion system consists of a very safe gas burner certified in accordance to the

American Gas Association Standard in USA and with the Canadian Gas Association in Canada.

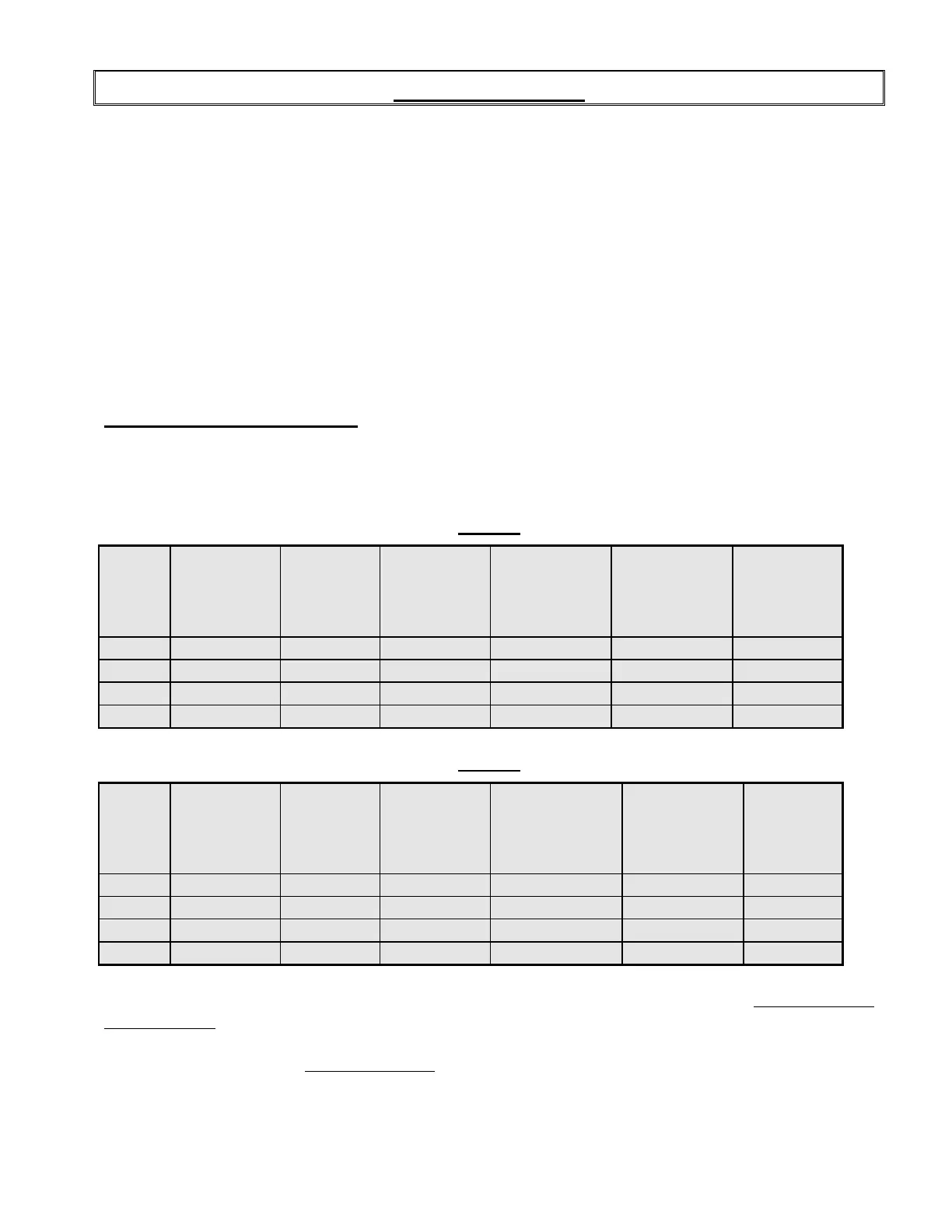

1.To the certified gas technician

The burner installed on DOYON gas fired ovens is set up and adjusted at the plant for a first class

operation. It is nevertheless necessary to verify on site the pressure at the burner input. The following

table indicates the pressures that must be set up to remain conform to the AGA standards or CGA.

SRO1G

GAS

TYPE

ALTITUDE

(FT)

(BTU)

EACH

OVEN

INPUT

PRESSURE

(Water column

OUTPUT

PRESSURE

(Water column

MANIFOLD

PRESSURE

(Water column

inches)

BURNER

ORIFICE

SIZE (DMS)

QTY=26)

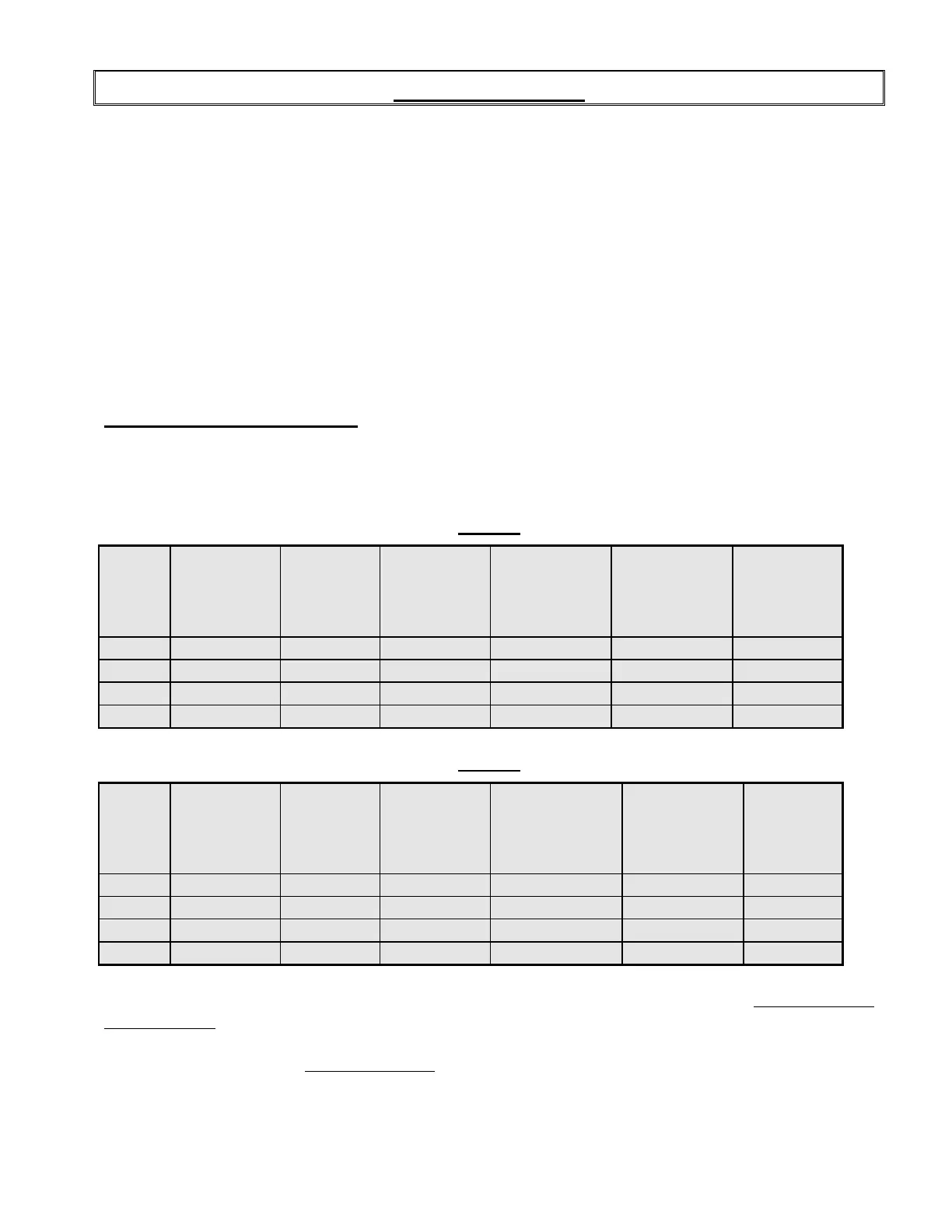

SRO2G

GAS

TYPE

ALTITUDE

(FT)

(BTU)

EACH

OVEN

INPUT

PRESSURE

(Water column

OUTPUT

PRESSURE

(Water column

MANIFOLD

PRESSURE

(Water column

inches)

BURNER

ORIFICE

SIZE (DMS)

QTY=26)

The burner used is adjusted for use with the gas indicated on the nameplate. It is nevertheless possible

to convert the burner to another gas by doing the modifications indicated in the CONVERSION

PROCEDURE provided with the oven. These modifications must be done carefully and completely

under the company's instruction to remain conform to A.G.A. or C.G.A standards. Refer to Doyon

Equipment to get the right CONVERSION KIT.

The pipe fittings compound must be certified for gas.

Loading...

Loading...