EXAMPLE:

Choosing 10 parameters sampling every 10 minutes will

provide over 4,460 samples or over 30 days before data

begins to be overwritten. While choosing 40 parameters

sampling every 5 minutes, the Data Profiler will only provide

over 1550 samples or over 5 days before data begins to be

overwritten.

Another consideration when configuring the profiler is that

sampling unneeded parameters or unnecessarily often may

lessen the life of the non-volatile memory in the control. The

non-volatile memory life when sampling 10 parameters

every 10 minutes, under normal conditions, the would be

more than100 years.

Histograms

Histograms offer the user a quick visual method to

understand the operation of the voltage regulator. The

histogram data and configuration can only be accessed via

communications. The histogram data is intended to be

viewed in bar graph form. Data is available for Percent

Regulation and the following Forward and Reverse demand

parameters:

•

Primary Load Current

•

Secondary Load Voltage

•

Secondary Source Voltage

•

Secondary Compensated Voltage

•

Load kVA

•

Load kW

•

Load kvar

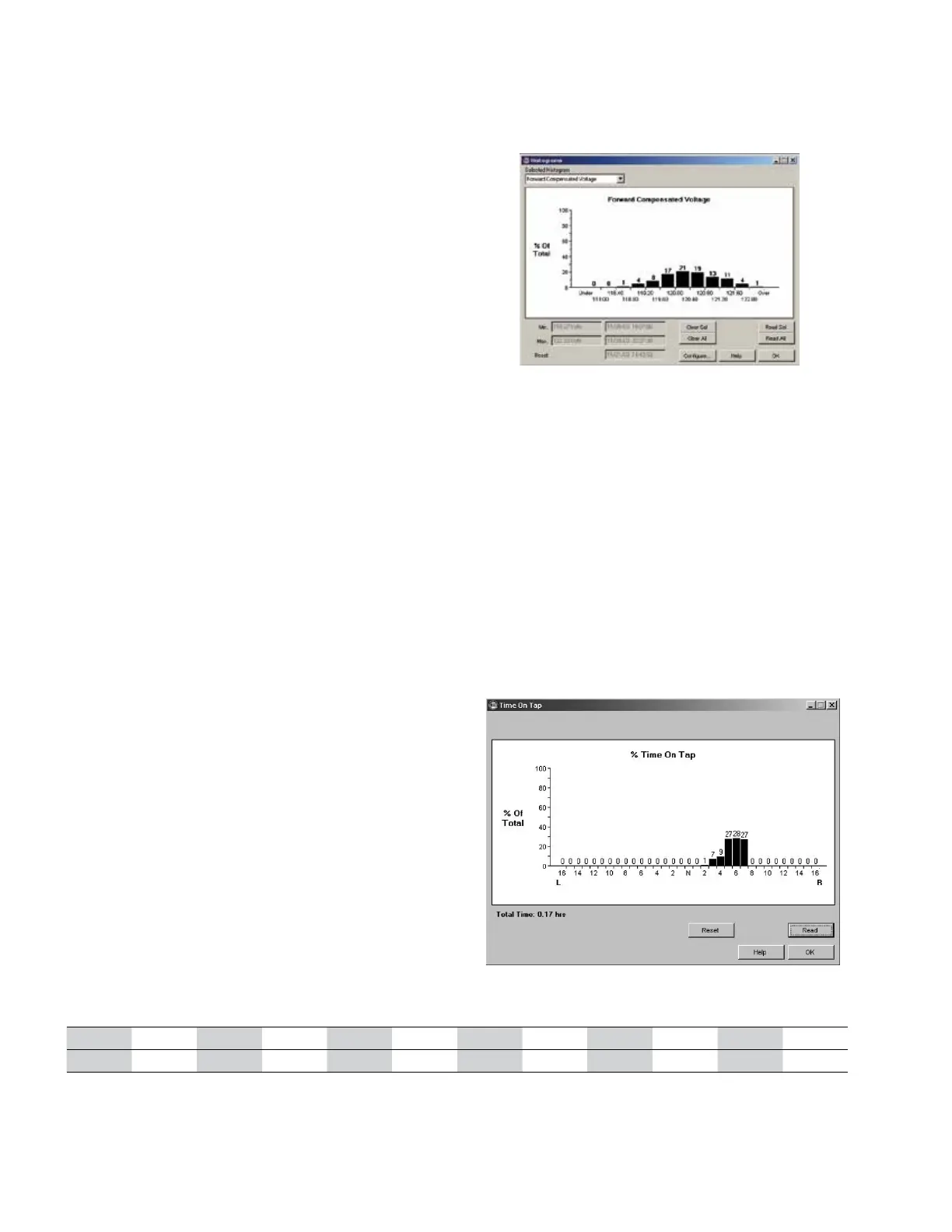

The histogram is also configured via communications. The

user sets a low and high limit for each parameter, creating a

range of acceptable values. The control divides this range

into 10 equal bins plus one Over and one Under bin for a

total of twelve bins; see Figure 7-8.

EXAMPLE:

The user chooses a low limit of 118 V and a high limit of 122

V for the Compensated Voltage parameter. The control

creates bins as shown in Figure 7-8.

The control then samples each of these parameters once

per minute and increments the appropriate bin. The

maximum and minimum value of the sampled parameter is

also stored with the histogram data (note that these values

may not be the same as the high and low value in the

demand metering section due to the sampling used).

After a period of time has passed, the histogram for this

example displays, using ProView NXG software to view, as

shown in Figure 7-9. The sample Histogram suggests that

the compensated voltage is varying greatly. The source of

this variation should be investigated. Possible causes

include an unstable system supply voltage, improper control

settings, or a greatly varying load.

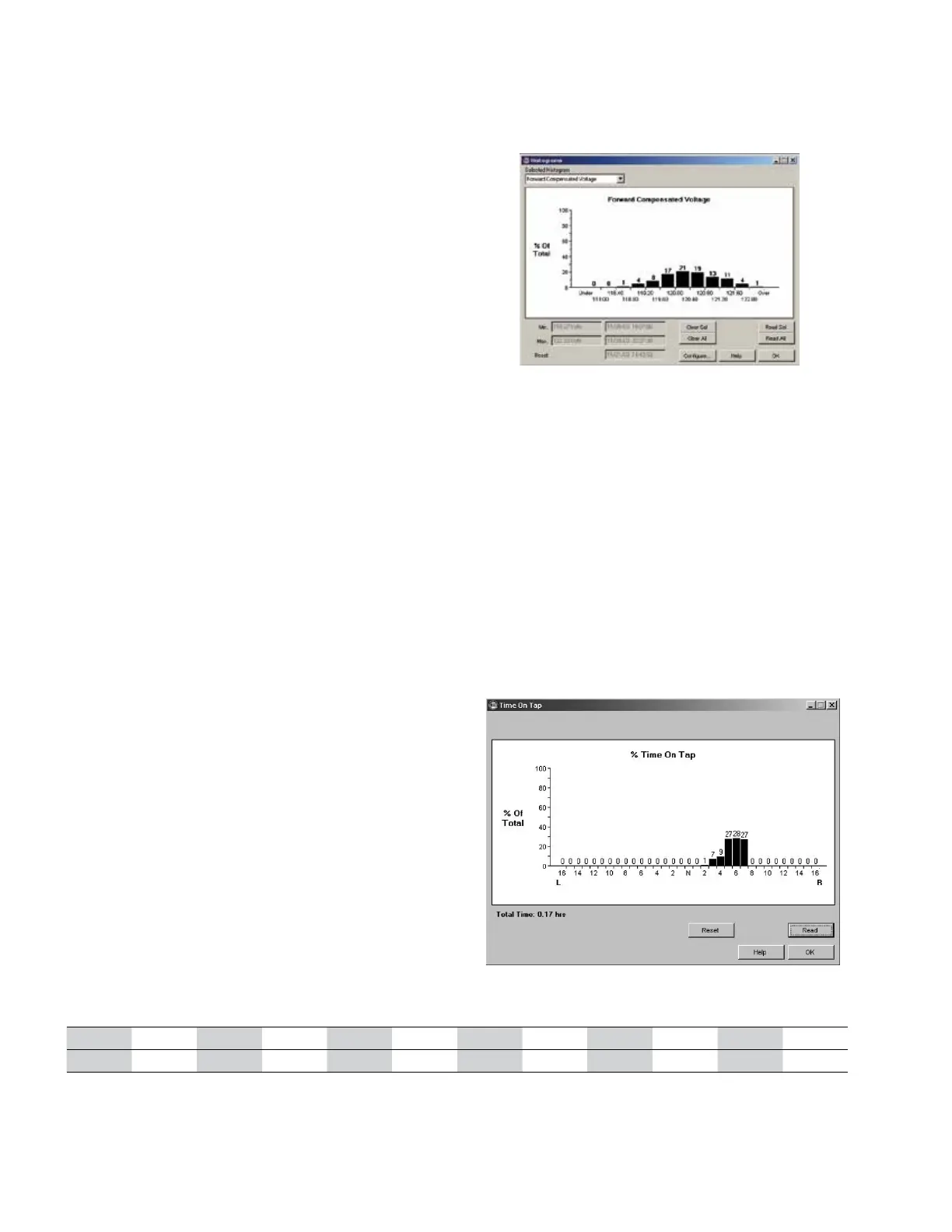

TIME-ON-TAP feature

The TIME-ON-TAP™ feature logs the amount of time spent

on each tap-changer position. The TIME-ON-TAP data is

accessed via the ProView NXG software and is viewed in

bar graph format; see Figure 7-10.

Under 118.0 to 118.4 to 118.8 to 119.2 to 119.6 to 120.0 to 120.4 to 120.8 to 121.2 to 121.6 to Over

118.0 118.4 118.8 119.2 119.6 120.0 120.4 121.8 121.2 121.6 122.2 122.0

Figure 7-8. Histogram sampling-bins example.

Figure 7-9. Sample histogram.

Figure 7-10. Sample TIME-ON-TAP bar graph.

100

CL-6 SERIES CONTROL INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS MN225016EN January 2016

Loading...

Loading...