from rotating by having a “flat” against the bottom of the

breaker horizontal top pan.

During reassembly, care must be taken to insure that the

two guide spacers are located in the slots of the top pan.

This permits the mechanism to float. Screws should be

tightened and then backed off one half turn to allow the

mechanism to float.

5-6 Lubrication

In general, the circuit breaker requires only moderate

lubrication at regular intervals. The use of a special lubri-

cant is required in a few places, and must be applied with

care. Only small quantities are needed. All excess must be

removed with a clean cloth to prevent any accumulation of

dust or dirt. Avoid getting any lubricant on insulation or other

electrical parts. Care must be taken to prevent any of the

molybdenum lubricant from reaching any current carrying

contact surface.

5-6.1 Lubrication Frequency

Under normal operating conditions, refer to Table 5.1 for the

recommended lubrication frequency for DSII circuit break-

ers by frame size. Special conditions, such as contaminated

environments, high temperatures and excessive humidity,

might dictate that a different schedule be considered.

NOTICE

ANY CIRCUIT BREAKER THAT HAS BEEN STORED SHOULD BE

OPERATED A MINIMUM OF FIVE TIMES BEFORE BEING PUT IN

SERVICE.

5-6.2 Lubricant Location

NOTICE

ALL PARTS OF THE LEVERING MECHANISM HAVE SUFFICIENT

LUBRICATION, AND SHOULD NOT REQUIRE ANY FURTHER ATTEN-

TION (FIGURE 5-7).

The following numbered lubrication point references corre-

spond to the numbers shown on Figures 5-8 through 5-12.

Molykote BR-2 Plus by Dow Corning (Molybdenum Disulphi-

de in Lithium Grease) or equivalent should be used sparingly

on the following:

1. Spring-charge indicator surface engaging with the cut-off

switch link

2. Cam surface operating the cut-off switch link

3. Pins on both ends of constraining link

4. Shunt trip moving armature surface

5. Curved surface of trip latch

6. Spring release moving armature surface

7. Several trip shaft points

8. Surface of cut-off switch link

9. Main spring pins on each end of crankshaft and fixed

ends

10. Rear face of oscillator

WARNING

BE CERTAIN THAT CIRCUIT BREAKER CONTACTS ARE OPEN AND

CLOSING SPRINGS DISCHARGED AFTER COMPLETING MAINTE-

NANCE ACTIVITIES. FAILURE TO DO SO COULD RESULT IN BODILY

INJURY.

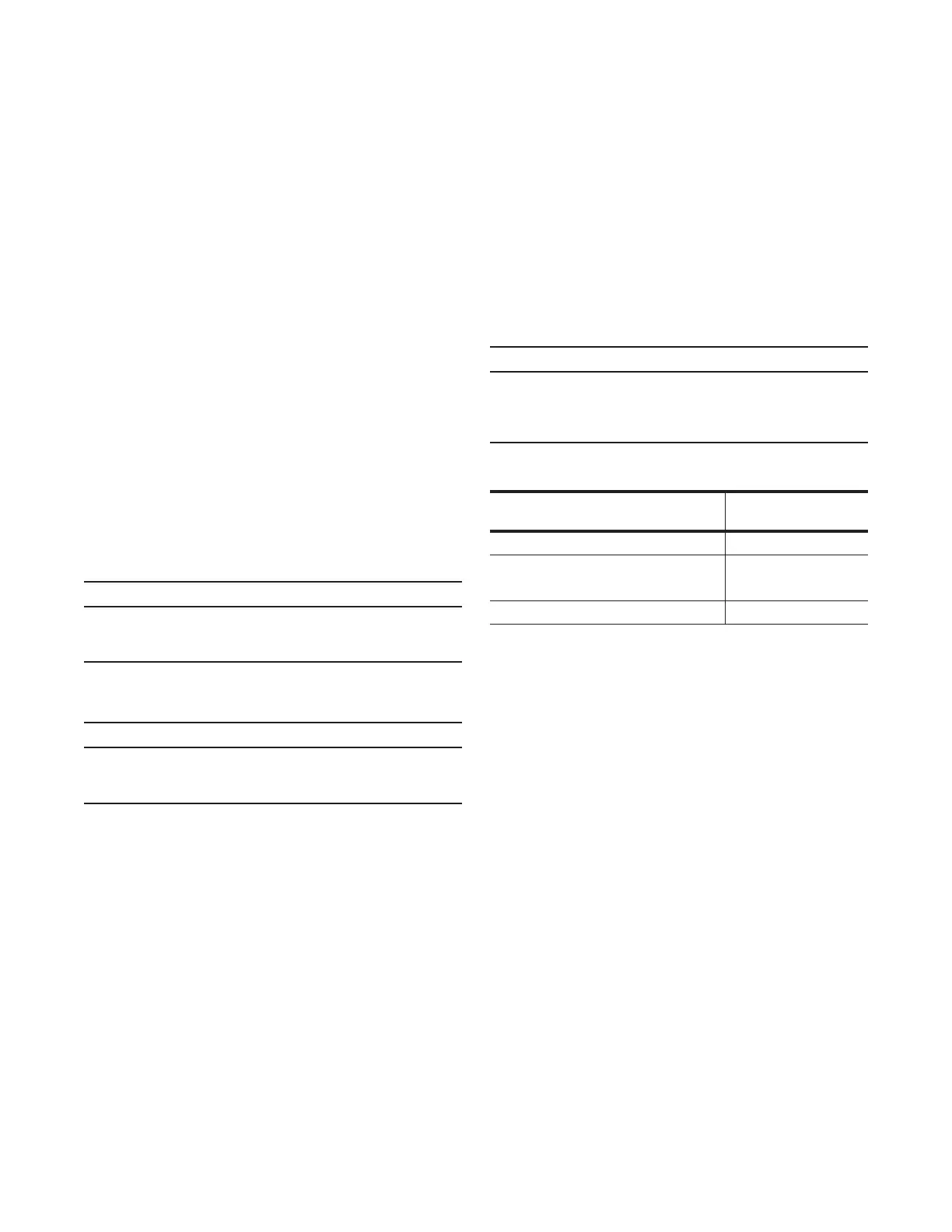

Table 5.1 Lubrication Frequency

Breaker Type Interval *

(Breaker Cycles)

DSII-308, DSII-508, DSLII-308 1750

DSII-608, DSII-516, DSII-616, 500

DSII-620, DSLII-516, DSLII-620

DSII-632, DSII-840/850 250

* Breaker Cycle - one no load open/close operation.

Effective July 2010

Instructional Book IB694C694-03

59

EATON CORPORATION www.eaton.com

Loading...

Loading...