13

TM293 MEDC DB3BM UL Technical Manual

SOUNDER/HORN – DB3BM UL TM293.A August 2022 www.eaton.com

5.0 MAINTENANCE

During the working life of the unit, it should require

little maintenance however; if abnormal or unusual

environmental conditions occur due to plant damage or

accident etc., then visual inspection is recommended.

WARNING! – The front driver cover of the unit, situated

underneath the thermoplastic main flare, which encloses

the loudspeaker driver shall not be opened as it is not for

field installation or maintenance use.

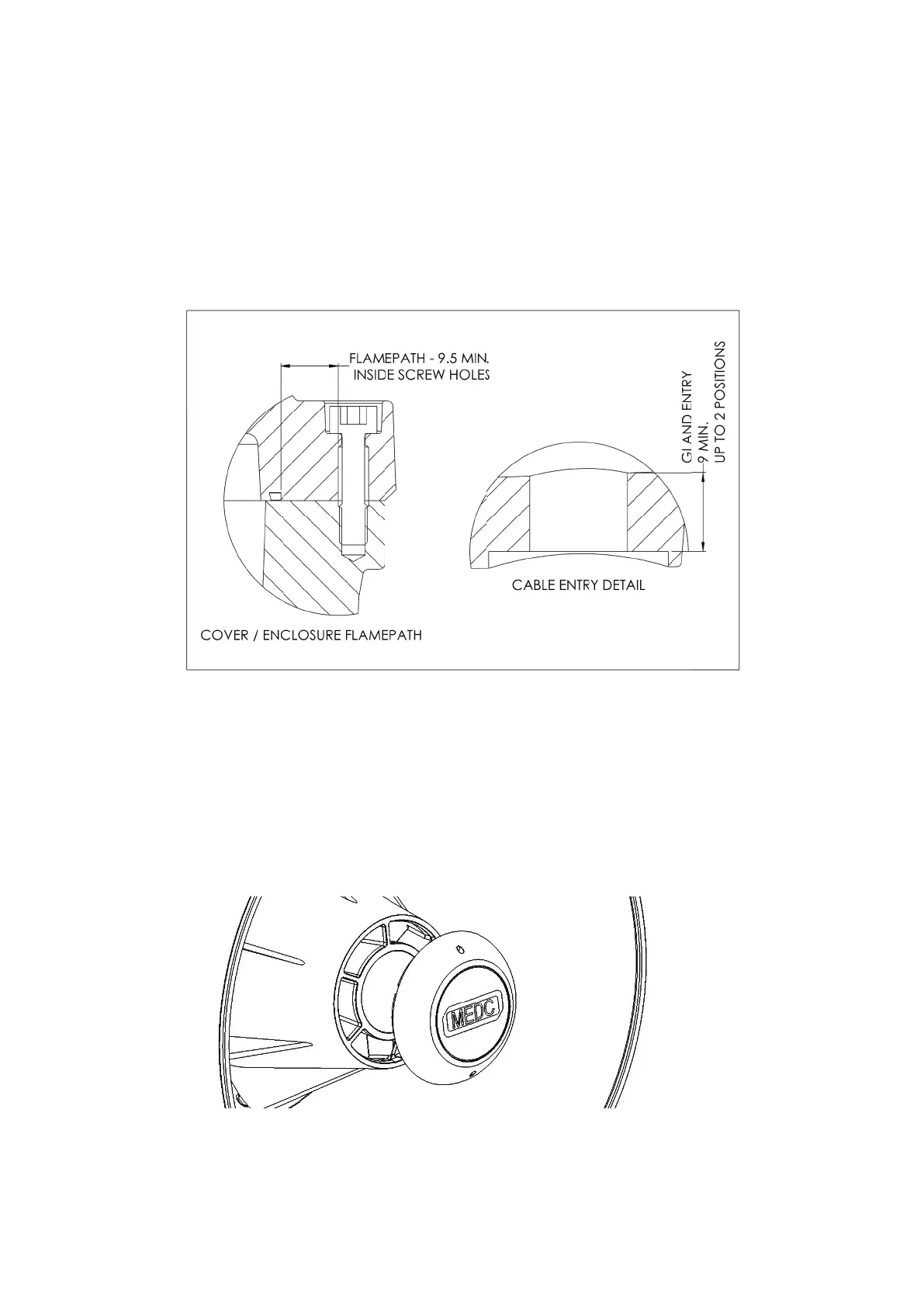

See below diagram for details of the flameproof joints

found in the unit. WARNING! – The flameproof joints

details below are not intended to be repaired.

Corrosion inhibiting grease, such as petrolatum or soap-

thickened mineral oils, may be applied to flameproof joint

surfaces before assembly. The grease, if applied, shall be

of a type that does not harden because of ageing, does

not contain an evaporating solvent, and does not cause

corrosion of the joint surfaces. Verification of suitability

shall be in accordance with the grease manufacturer’s

specifications.

Aluminium Alloy cover joints must be cleaned before

replacing cover

If the unit requires cleaning, the only clean exterior with

a damp cloth to avoid electro-static charge build up.

If a unit fault should occur, then the unit can be repaired

by MEDC

If you acquired a significant quantity of units, then it is

recommended that spares are also made available. It

should be noted that if damaged the external thermoplastic

horn may be replaced as a complete part or the snap in end

cap may be replaced separately. Please discuss your spares

requirements with the Technical Sales Engineers at Eaton

MEDC.

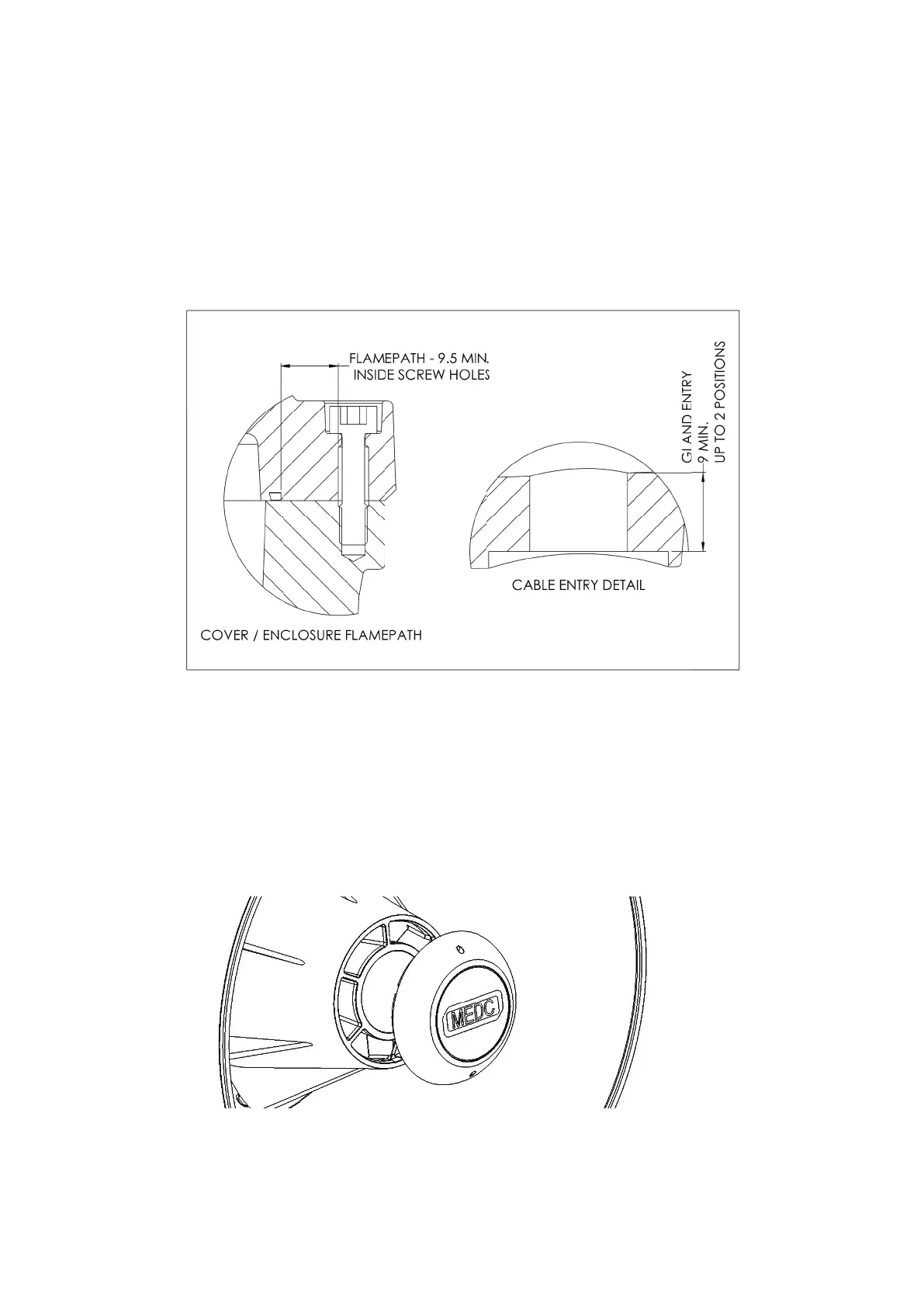

Snap in end cap

can be replaced

as a spare part,

see below

Loading...

Loading...