AGL_HP_VS_YHV_RG_RT_EN_Rev00 17

In order to ensure positive compressor protection, discharge gas temperature protection is required

for any application with Copeland compressors.

The maximum discharge gas temperature is 135 °C for all YHV*RG and YHV*RT models.

Discharge gas temperature protection is the "fall-back" for failure of the system control. It is essential

that proper control of both the evaporating and condensing pressures and the superheat is

maintained and has the ability to cope with all likely conditions and high loads. Reliance on protectors

will cause inadequate system performance and short cycling.

NOTE: The maximum discharge gas temperatures indicated in this chapter are valid for safe

operation within the approved application envelope. The discharge temperature protection

has the function of a compressor protection device; it is not designed to control the operating

envelope. For compressor envelope and superheat control, a dedicated control device must

be used.

3.7.1 Excessive discharge gas temperatures

A few of the possible consequences of excessive discharge gas temperatures are listed below:

Since the oil circulates in the system with the ref rigerant, it is subjected to high discharge gas

temperatures. If the discharge gas temperature becomes too high, the so-called "cooking" effect

will occur (heating of oil under exclusion of air). Carbon deposits can form at points of high

temperature, for example on the valves, oil channels, oil filters, etc. The oil lubricity will be reduced

and a progressive wear process will occur which will prematurely damage the compressor.

The stability of the ref rigerant can also be affected, particularly if traces of contaminant are

present.

The problems described above f requently occur simultaneously, particularly since the chemical

reaction speed approximately doubles with every 10 °C temperature rise. This directly leads to

chemical reactions of the oil with the refrigerant and the compounds extracted from sealants and

insulation material. As a consequence, contaminants of various types, among them acids, will form

inside the system.

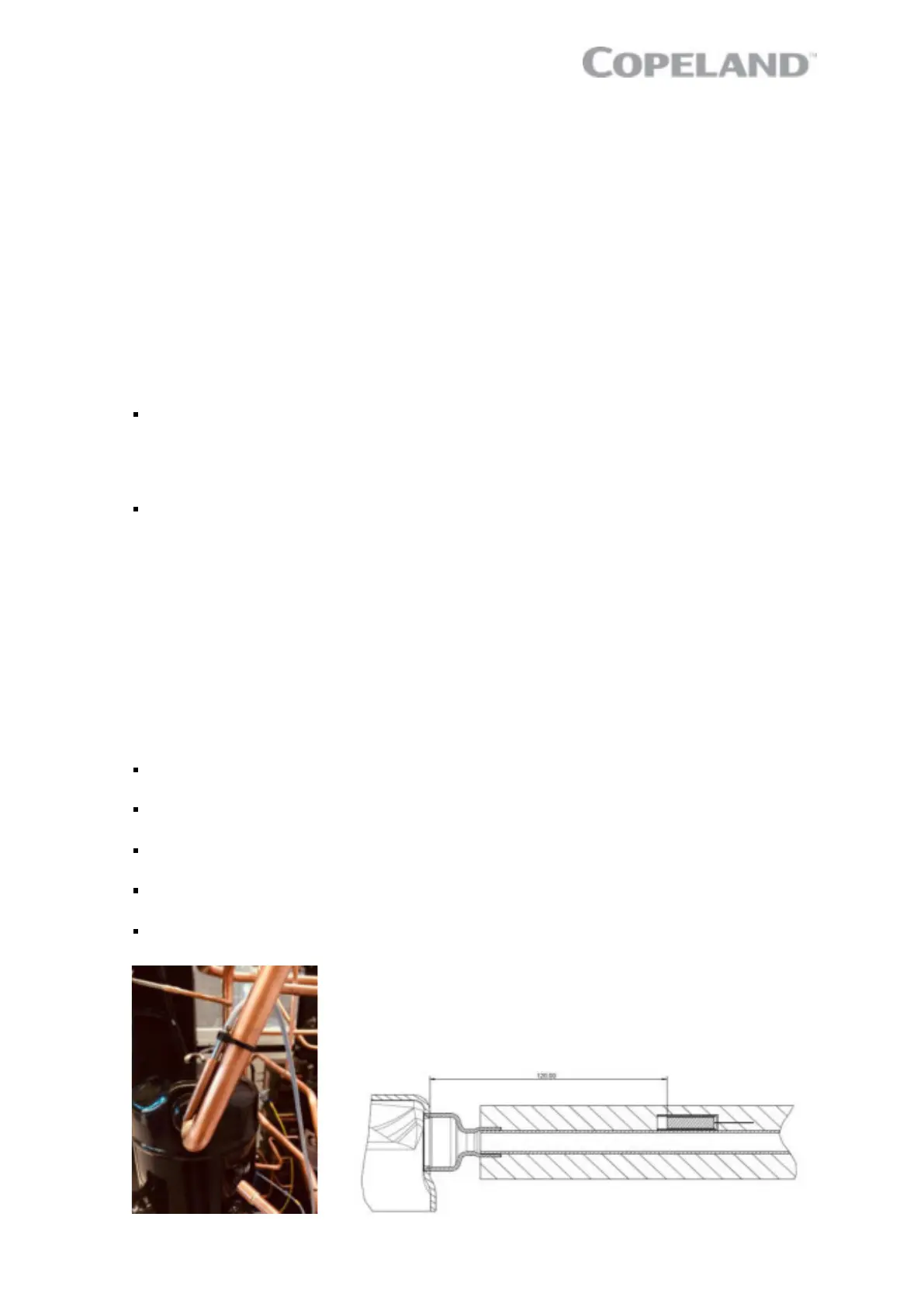

3.7.2 Discharge line temperature sensor

Variable-speed compressors need an external Discharge Line Temperature (DLT) sensor. The

correct reading of the sensor is fundamental for discharge line temperature control. The sensor must

ensure good accuracy and acceptable dynamic behaviour.

Please follow the recommendations below for sensor assembly:

The DLT sensor must be attached to the compressor discharge line at a distance of 120 mm from

the compressor discharge fitting.

The sensor must be installed in a copper sleeve, to improve response time and to reduce setoff.

The copper sleeve must be brazed on the surface of the pipe.

Use thermal compound to improve heat transfer from sleeve to sensor. The thermal compound

must be approved for the applied temperature ranges.

For best response and to reduce the impact of ambient temperature the pipe including the sensor

must be insulated.

Protect the sensor f rom being moved or removed from its position by transport, vibration or any

other incident.

Figure 16: Discharge temperature sensor mounting

Loading...

Loading...