AGL_HP_VS_YHV_RG_RT_EN_Rev00 35

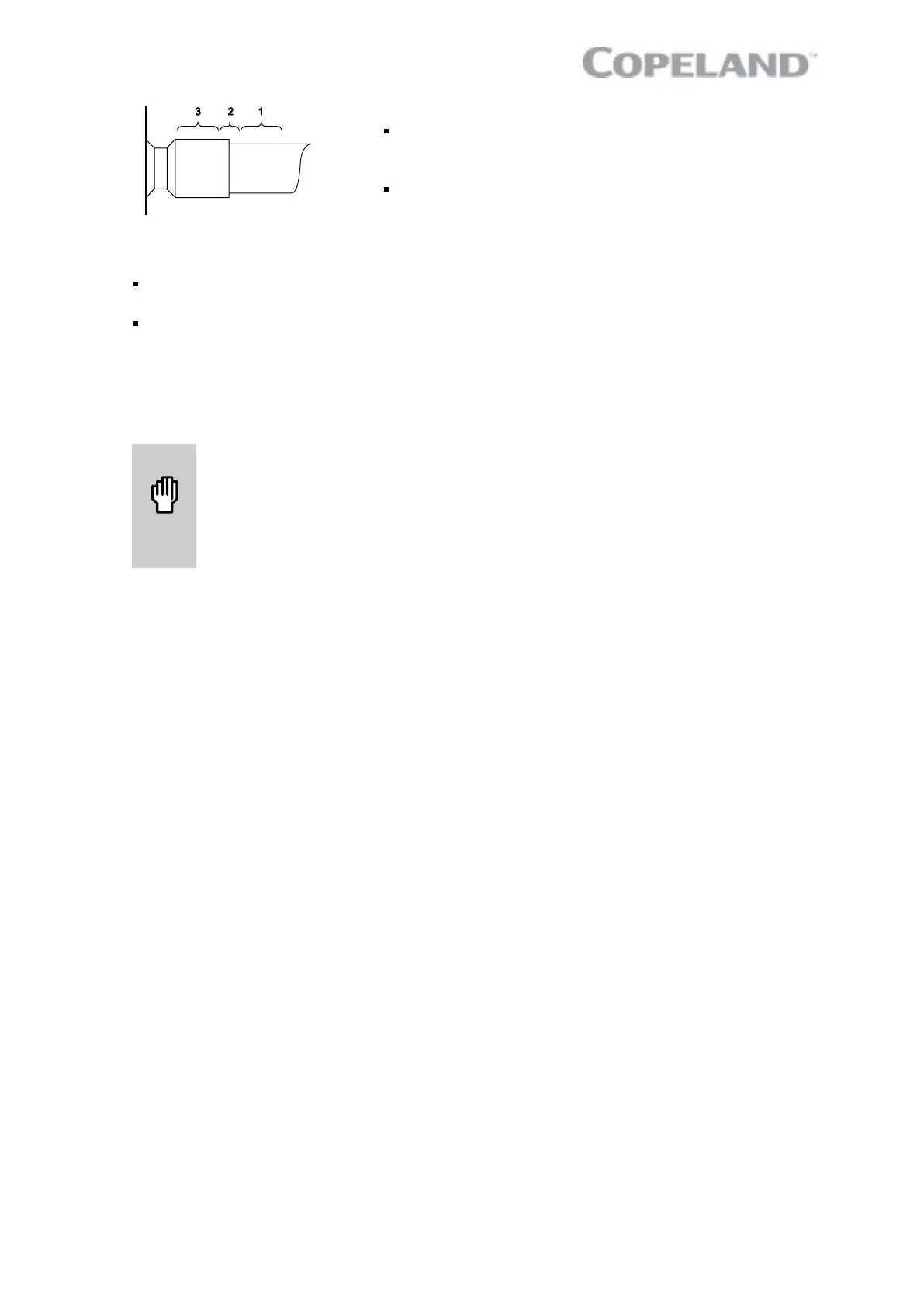

To disconnect:

Using a pipe cutting tool, cut off the suction and discharge

lines in such a manner that the new compressor can easily be

re-connected into the system.

Heat joint areas 2 and 3 slowly and uniformly until the braze

material sof tens and the tube end can be pulled out of the

fitting.

To reconnect:

Recommended brazing material: Silfos with minimum 5 % silver or silver braze used on other

compressors.

Due to the different thermal properties of steel and copper, brazing procedures may have to be

changed from those commonly used.

NOTE: Since the discharge stub contains a check valve, care must be taken not to overheat

it to prevent brazing material from flowing into it.

6.5 Replacing a compressor

CAUTION

Inadequate lubrication! Bearing destruction! For systems with a

accumulator, exchange the accumulat

or after replacing a compressor with a

burned-

out motor. The accumulator oil return orifice or screen may be plugged

with debris or may become plugged. This will result in starvation of oil to the

new compressor and a second failure.

oil completely from the replaced compressor.

6.5.1 Compressor replacement

In the case of A2L- or A3-refrigerant compressor replacement, the oil has to be drained out of the

compressor and the compressor should be flushed with dry nitrogen. DO NOT close the stubs with

plugs.

In the case of a motor burnout, the majority of contaminated oil will be removed with the compressor.

The rest of the oil is cleaned through the use of suction and liquid line filter dryers. A 100 % activated

alumina suction line filter dryer is recommended but must be removed after 72 hours.

It is highly recommended that the suction accumulator be replaced if the system contains

one. This is because the accumulator oil return orifice or screen may be plugged with debris or may

become plugged shortly after a compressor failure. This will result in starvation of oil to the

replacement compressor and a second failure. When a compressor is exchanged in the field, it is

possible that a major portion of the oil may still be in the system. While this may not affect the

reliability of the replacement compressor, the extra oil will add to rotor drag and increase power

usage.

6.5.2 Start-up of a new or replacement compressor

Rapid charging only on the suction side of a scroll-equipped system can occasionally result in a

temporary no-start condition for the compressor. The reason for this is that, if the flanks of the scrolls

happen to be in a sealed position, rapid pressurisation of the low side without opposing high-side

pressure can cause the scrolls to seal axially. As a result, until the pressures eventually equalise,

the scrolls can be held tightly together preventing rotation. The best way to avoid this situation is to

charge on both the high and low sides simultaneously at a rate which does not result in axial loading

of the scrolls.

A minimum suction pressure specified in the published operating envelope must be maintained

during charging. Allowing the suction pressure to drop below that value may overheat the scrolls and

cause early drive bearing and moving parts damage. Never install a system in the field and leave it

unattended when it has no charge, a holding charge, or with the service valves closed without

securely electrically locking out the system. This will prevent unauthorised pers onnel from

accidentally operating the system and potentially ruining the compressor by operating with no

ref rigerant. Do not start the compressor while the system is in a deep vacuum. Internal arcing

may occur when a scroll compressor is started in a vacuum causing burnout of the internal lead

connections.

Figure 25: Tube connecting areas

Loading...

Loading...