7. Attach electrical output wiring from both pickoffs to terminal connection TB2 and

TB3.

8. Attach electrical output wiring from electrical accessories (conduit wiring) to

terminal connection TB1, number 3 for channel A, and number 5 for channel B.

9. Secure all electrical wiring.

10. Secure screws of preamplifier bracket in to the enclosure.

11. Return cover and secure.

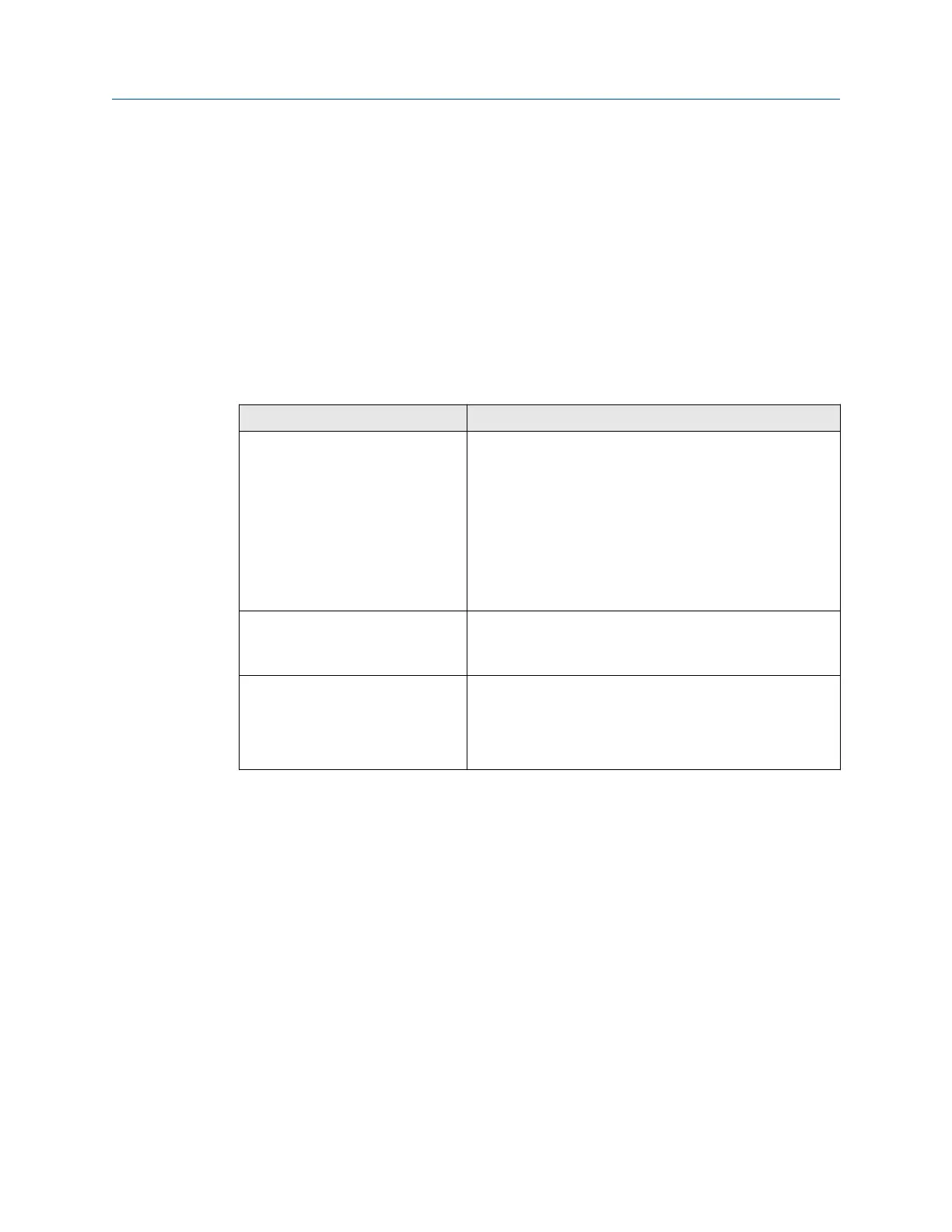

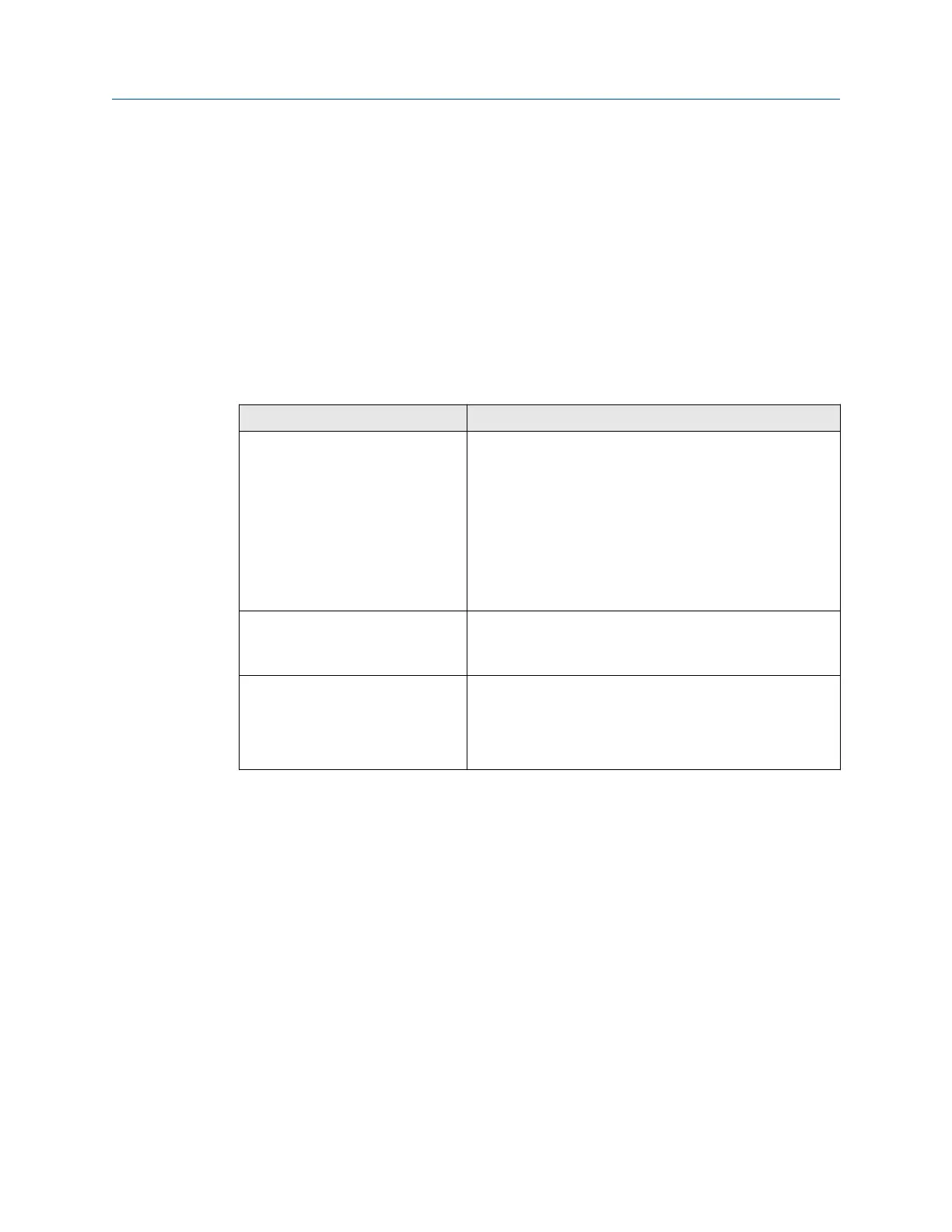

9.8 Planned maintenance tasks

Table 9-2: Planned maintenance tasks

Task Recommended action

Inspect Implement a periodic inspection program to ensure all parts

are free from damage due to process, ambient or other

abnormal conditions.

• Internal components: rotor, upstream to downstream

cone, etc.

• Meter body housing, external flanges, flamepath.

• Bolting

• Electrical connections.

Clean Use a non-toxic metal cleaning solvent.

Do not use common petrochemical solvents like Benzene,

Toluene or Xylene as they can pose potential health hazards.

Monitor corrosion / erosion / wear A careful review of turbine meter proving history, such as

turbine meter factor control charts, can reveal potential

problems with turbine meter measurements. Examples

include bearing drag due to wear or an increased internal

cross-sectional area due to erosion.

Planned maintenance User manual

March 2019 P/N 3-9008-515

98 Daniel Series 1500 Liquid Turbine Meter, NPS 3-24

Loading...

Loading...