EDR and ETR Valves

Instruction Manual

Form 5050

August 2006

11

6. For spring-loaded PTFE V-ring packing,

tighten the packing flange nuts until the shoulder on

the packing follower (key 13, figure 4) contacts the

bonnet.

For graphite packing, tighten the packing flange

nuts to the maximum recommended torque shown in

table 4. Then, loosen the packing flange nuts, and

retighten them to the recommended minimum torque

shown in table 4.

For other packing types, tighten the packing flange

nuts alternately in small equal increments until one

of the nuts reaches the minimum recommended

torque shown in table 4. Then, tighten the remaining

flange nuts until the packing flange is level and at a

90-degree angle to the valve stem.

Note

If the valve has ENVIRO-SEAL

live-loaded packing installed (figure 9,

10, or 11), see the Fisher instruction

manual entitled ENVIRO-SEAL Packing

System for Sliding-Stem Valves for

packing instructions.

If the valve has HIGH-SEAL

Heavy-Duty live-loaded packing

installed (figure 8), see the Fisher

instruction manual entitled HIGH-SEAL

Live-Loaded Packing System for

packing instructions.

Packing Lubrication

WARNING

To avoid personal injury or property

damage resulting from fire or

explosion, do not lubricate packing

used in oxygen service or in

processes with temperatures over

260_C (500_F).

Packing used in oxygen service or in processes with

temperatures over 260_C (500_F) should not be

lubricated. If a lubricator or lubricator/isolating valve

(see figure 7) is required for the packing, install the

lubricator or lubricator/isolating valve into the

threaded hole in the side of the bonnet (see

figure 7). Use a good quality silicon-base lubricant.

To operate the lubricator, simply turn the cap screw

clockwise to force the lubricant into the packing box.

The lubricator/isolating valve operates the same way

except the isolating valve must first be opened and

then closed after lubrication is completed.

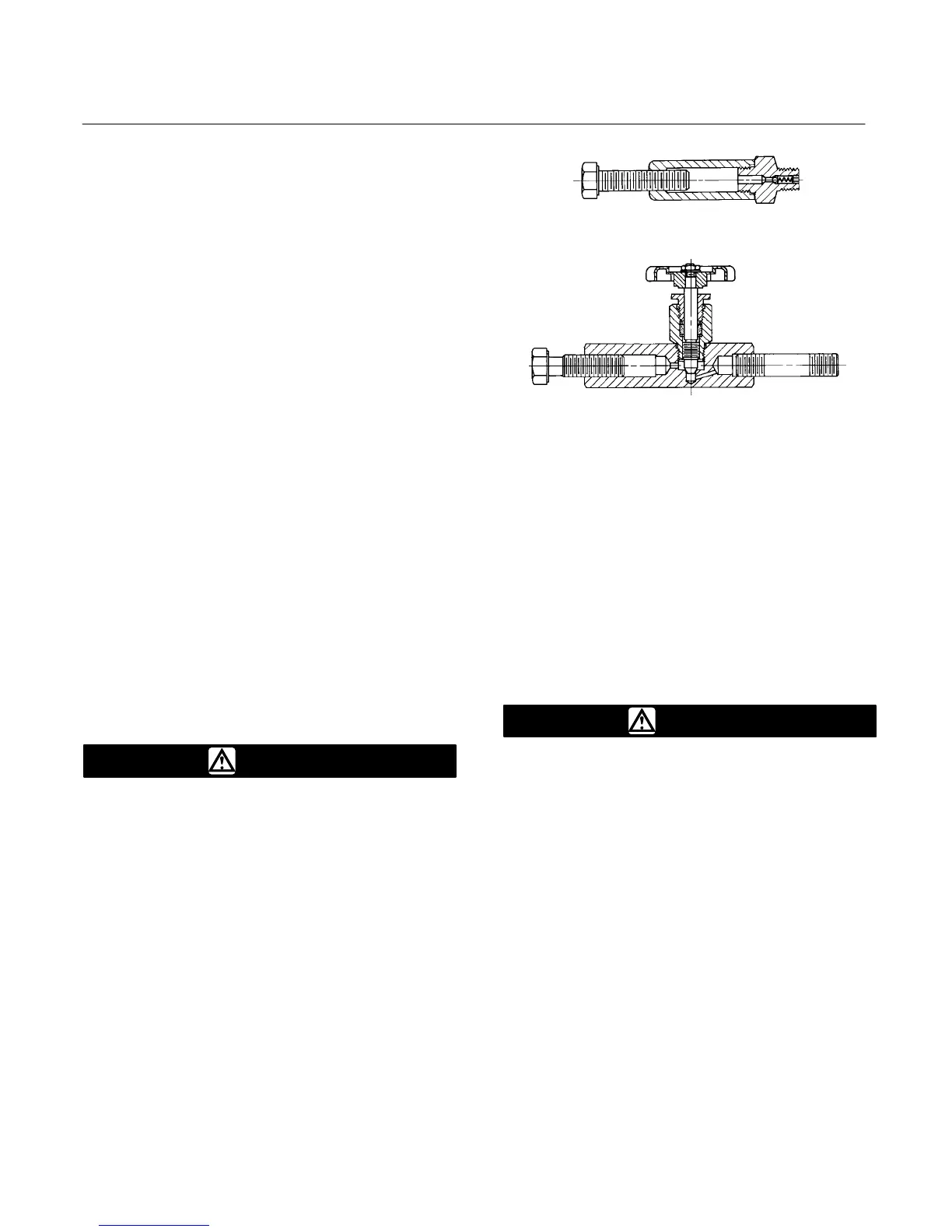

LUBRICATOR

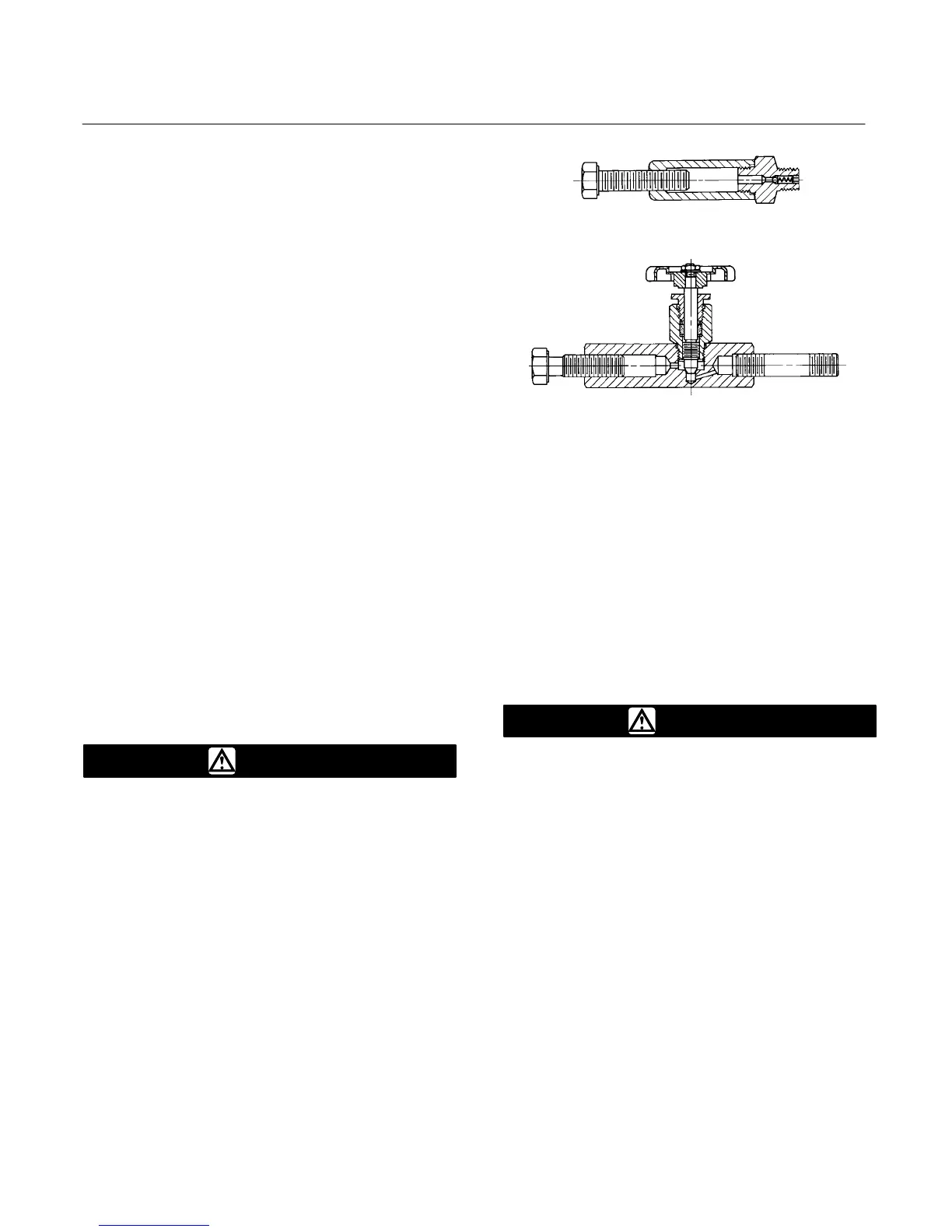

LUBRICATOR/ISOLATING VALVE

10A9421-A

AJ5428-D

A0832-2/IL

Figure 7. Lubricator and Lubricator/Isolating Valve

Parts Ordering

Each body-bonnet assembly is assigned a serial

number which can be found on the valve body. This

same number also appears on the actuator

nameplate when the valve is shipped from the

factory as part of a control valve assembly. Refer to

the serial number when contacting your Emerson

Process Management sales office for technical

assistance. When ordering replacement parts, refer

to the serial number and to the eleven-character part

number for each part required from the following

parts kit or parts list information.

WARNING

Use only genuine Fisher replacement

parts. Components that are not

supplied by Emerson Process

Management should not, under any

circumstances, be used in any Fisher

valve, because they will void your

warranty, might adversely affect the

performance of the valve, and might

jeopardize worker and workplace

safety.

Note

Neither Emerson, Emerson Process

Management, Fisher, nor any of their

affiliated entities assumes

responsibility for the selection, use

and maintenance of any product.

Responsibility for the selection, use,

and maintenance of any product

remains with the purchaser and

end-user.

Loading...

Loading...