EDR and ETR Valves

Instruction Manual

Form 5050

August 2006

2

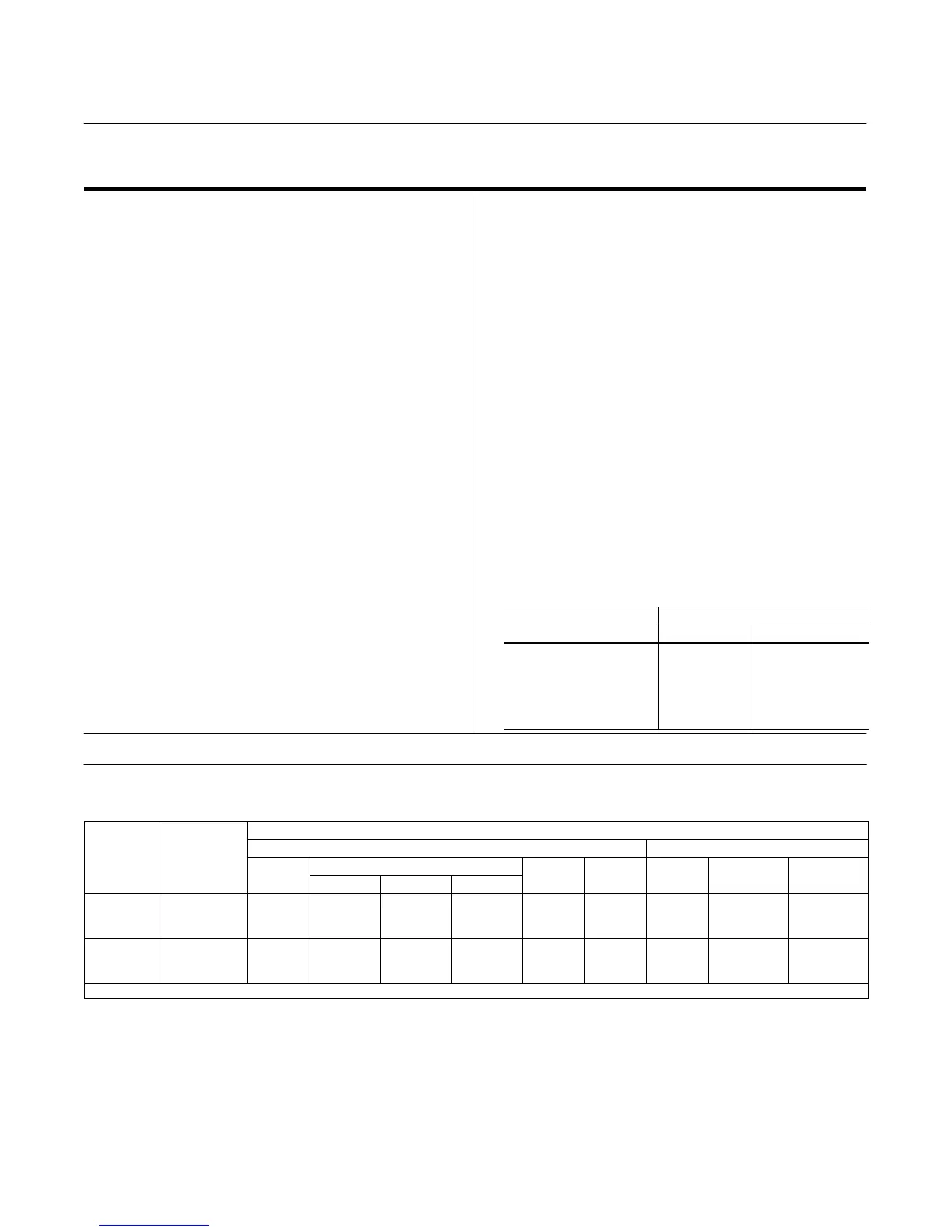

Table 1. Specifications

Available Valve Constructions

See table 2

End Connection Styles

Cast Iron Valves

Flanged: Class 125 flat-face or 250 raised-face

flanges per ASME B16.1

Screwed: Consistent with ASME B16.4

Steel and Stainless Steel Valves

Flanged: Class 150, 300, and 600 raised-face or

ring-type joint flanges per ASME B16.5

Screwed or Socket Welding: All available ASME

B16.11 schedules that are consistent with Class

600 per ASME B16.34

Buttwelding: Consistent with ASME B16.25

Maximum Inlet Pressure

(1)

Cast Iron Valves

Flanged: Consistent with Class 125B or 250B

pressure-temperature ratings per ASME B16.1

Screwed: Consistent with Class 250

pressure-temperature ratings per ASME B16.4

Steel and Stainless Steel Valves

Flanged: Consistent with Class 150, 300, and

600

(2)

pressure-temperature ratings per ASME

B16.34

Screwed or Welding: Consistent with Class 600

pressure-temperature ratings per ASME B16.34

Shutoff Classification

Design EDR: ANSI/FCI 70-2 and IEC 60534-4

Class II (standard); Class III for valves with a

graphite piston ring and 78 mm (3.4375 inch) or

larger port diameter

Design ETR: Standard air test

(0.05 mL/minute/psid/inch of port diameter) using

air at service pressure drop or 3.5 bar (50 psi),

whichever is lower; or ANSI/FCI 70-2 and

IEC 60534-4 Class V (optional) with PTFE seats;

Class IV or V (optional) with metal seats

Flow Characteristics

Linear (all cages), quick-opening, or equal

percentage

Flow Directions

Linear, Quick Opening, or Equal Percentage

Cage: Normally up,

Whisper Trimr I Cage: Always down

Approximate Weights

VALVE SIZE,

INCHES

WEIGHT

kg Pounds

1 & 1.25

1.5

2

2.5

3

4

14

20

39

45

54

77

30

45

67

100

125

170

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for the valve should not be exceeded.

2. Certain bonnet bolting material selections may require a Class 600 easy-e valve assembly to be derated. Contact your Emerson Process Management sales office.

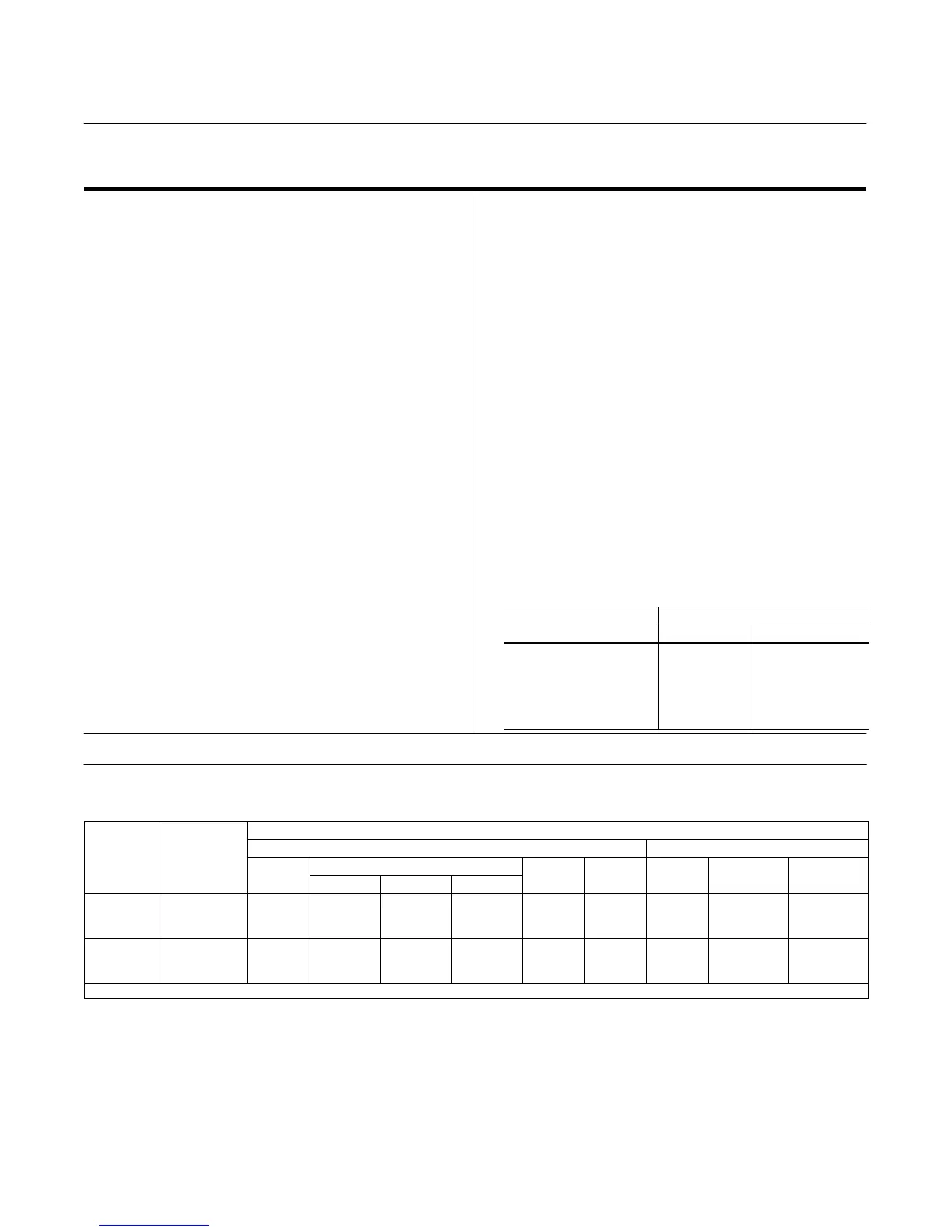

Table 2. Available Valve Constructions

DESIGN

VALVE

SIZE,

INCHES

VALVE MATERIAL AND END CONNECTION STYLE

Carbon Steel, Alloy Steel, or Stainless Steel Valve Cast Iron Valve

Screwed

RF or RTJ Flanged

Butt-

welding

Socket

Weld

Screwed

Class 125B

FF Flanged

Class 250B

RF Flanged

Class 150 Class 300 Class 600

EDR

1, 1.5, or 2

1.25

2.5, 3, or 4

X

X

- - -

X

- - -

X

X

- - -

X

X

- - -

X

X

- - -

X

X

- - -

- - -

X

X

- - -

X

- - -

X

X

- - -

X

ETR

1, 1.5, or 2

1.25

2.5, 3, or 4

X

X

- - -

X

- - -

- - -

X

- - -

- - -

X

- - -

- - -

X

- - -

- - -

X

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

X = Available Construction

Loading...

Loading...