EDR and ETR Valves

Instruction Manual

Form 5050

August 2006

3

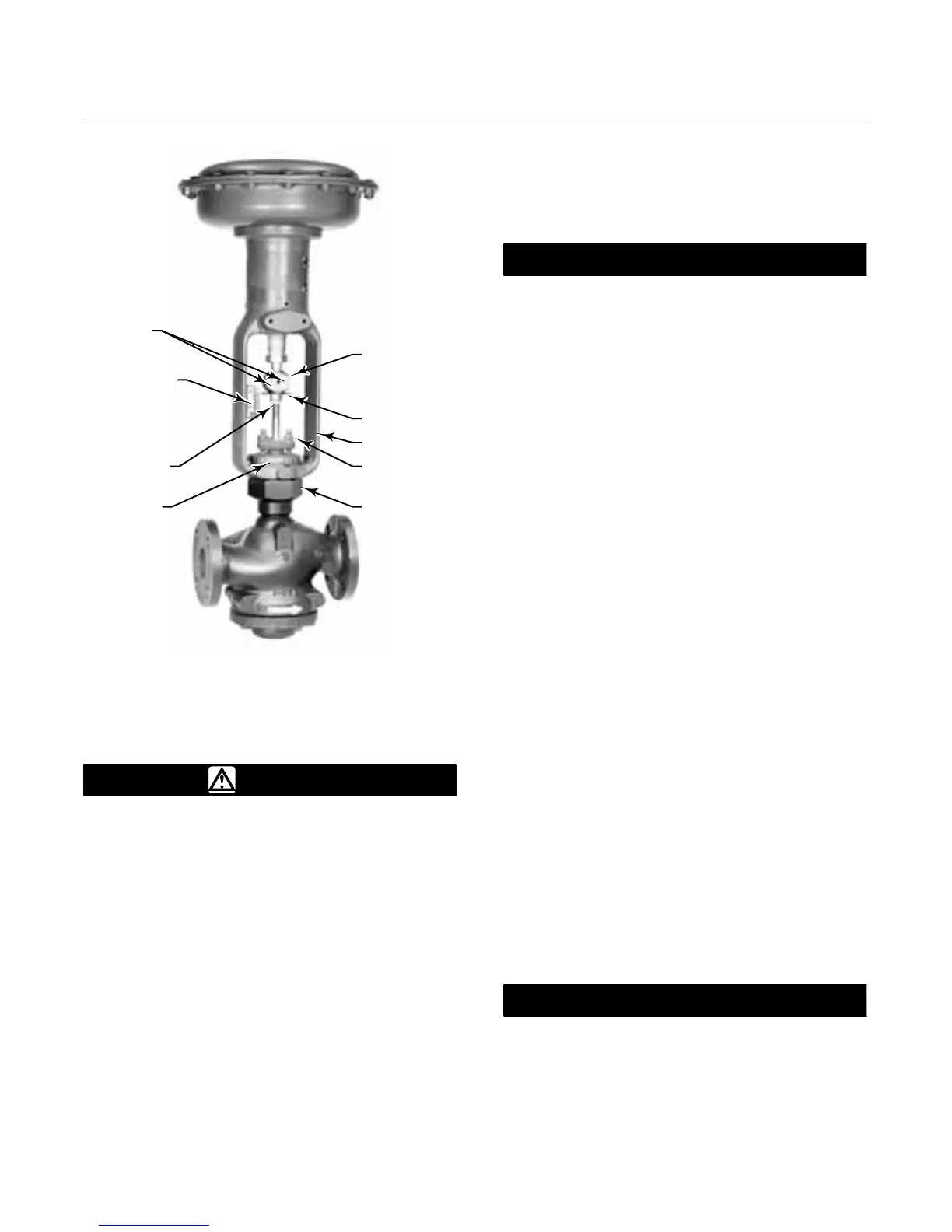

CAP SCREWS

INDICATOR SCALE

STEM LOCKNUTS

YOKE LOCKNUT

STEM

CONNECTOR

INDICATOR DISK

ACTUATOR

YOKE

PACKING

FLANGE

NUTS

BONNET

W2080-1 / IL

Figure 2. Actuator Mounting

Installation

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any installation operations.

To avoid personal injury or property

damage resulting from the sudden

release of pressure, do not install the

valve assembly where service

conditions could exceed the limits

given on the valve and actuator

nameplates. Use pressure-relieving

devices as required by accepted

industry, local, state, or Federal codes,

and good engineering practices.

Check with your process or safety

engineer for any other hazards that

may be present from exposure to

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

CAUTION

The valve configuration and

construction materials were selected

to meet particular pressure,

temperature, pressure drop, and

controlled fluid conditions. Because

some body/trim material combinations

are limited in their pressure drop and

temperature range capabilities, do not

exceed these conditions without first

contacting your Emerson Process

Management sales office.

Inspect the valve and pipelines to

ensure they are not damaged, are

clean, and free of foreign material.

1. Before installing the valve, inspect the valve and

associated equipment for any damage and any

foreign material.

2. Make certain the valve body interior is clean, that

pipelines are free of foreign material, and that the

valve is oriented so that pipeline flow is in the same

direction as the arrow (see figure 2) on the side of

the valve.

3. The control valve assembly can be installed in

any orientation unless limited by seismic criteria.

However, the normal method is with the actuator

vertical above the valve body (see figure 2). Other

positions may result in uneven valve plug and cage

wear, and improper operation. With some valves, the

actuator may also need to be supported when it is

not vertical. For more information, consult your

Emerson Process Management sales office.

4. Use accepted piping and welding practices when

installing the valve in the line. If a post-weld heat

treatment process is to be applied to the valve end

connections, and the valve has composition or

elastomer trim parts, remove the trim to avoid

damage to the soft parts.

CAUTION

Depending on valve body materials

used, post weld heat treating may be

required. If so, damage to internal

elastomeric and plastic parts, as well

as internal metal parts is possible.

Loading...

Loading...