15

8. Slowly pour new oil into the reservoir through the oil drain/

fill port. Continue pouring until excess oil begins flowing

from the concentric vents around the oil drain/fill port. This

indicates that the reservoir is full.

9. After adding oil, wipe the oil drain/fill plug with a clean rag

and reinstall it. Torque to 13-16 ft-lb [17.6-21.7 Nm].

10. Place the pump in the normal (horizontal) operating position,

with the carrying handle facing up.

11. Check the oil level indicator. Verify that the oil level is up to

the FULL mark and that the reservoir is not overfilled. Refer

to Figure 8.

• If the pump was previously operated with a very low oil level or

run until the reservoir was emptied, perform the pump priming/

air purging procedure before using the pump. Refer to Section

11.5.

• If reservoir is accidentally overfilled (oil level above full mark),

drain excess oil before using the pump.

11.4 Oil Change

1. Be sure that hydraulic torque wrench is fully retracted.

2. Be certain that pump is o and that all hydraulic pressure is

fully relieved. Refer to Section 10.0 for additional information.

3. Disconnect pump AC power cord from electrical outlet.

4. Disconnect hydraulic hoses from pump.

5. Place the pump on a on a stable and level work surface.

6. Place a suitable pan or container of appropriate capacity

under the oil drain/fill plug.

• Pump total oil capacity (including reservoir and pump element

housing) is approximately 1.14 gallons [4.33 liters]. Be sure the

pan or container used is large enough to hold all the drained

oil.

• DO NOT operate the pump motor to drain the oil. Serious

permanent damage to pump internal components may result.

Such damage is not covered under warranty.

• Remove and dispose of used hydraulic oil in accordance with

all applicable laws and regulations.

7. Remove the oil drain/fill plug. Allow all used oil to drain

completely from the reservoir into the pan or container. It

may be necessary to tilt the pump slightly forward to drain

all the used oil.

8. Refill the reservoir with new hydraulic oil as described in

Section 11.3.

9. Perform the pump priming/air purging procedure. Refer to

the instructions in Section 11.5.

11.5 Pump Priming/Air Purging

Always perform the pump priming/air purging procedure after

completing an oil change.

This procedure should also be performed if the pump reservoir

has been refilled with oil after being accidentally run dry (with

little or no oil remaining in reservoir).

The pump will typically make a slapping, sloshing or

whirring noise if air pockets are present inside the pump element

housing. If the pump is not primed, there will be either very little

noise or an erratic sounding noise.

Perform the pump priming/air purging procedure as described in

the following steps:

1. Be certain that pump is o and that all hydraulic pressure is

fully relieved. Refer to Section 10.0 for additional information.

2. Disconnect hydraulic hoses from pump couplers.

3. With hoses disconnected, start and run the pump for

approximately 10 seconds at a pressure setting of 3,250 psi

[225 bar] or higher. This will remove any air trapped in the

pump element housing.

4. Stop the pump. Verify that hydraulic pressure gauge

indicates zero (0) psi/bar.

5. Repeat steps 3 and 4 as needed (typically 2-3 times).

6. Reconnect hydraulic hoses. Verify that pump operates

without making abnormal noises and that torque wrench

movement is smooth.

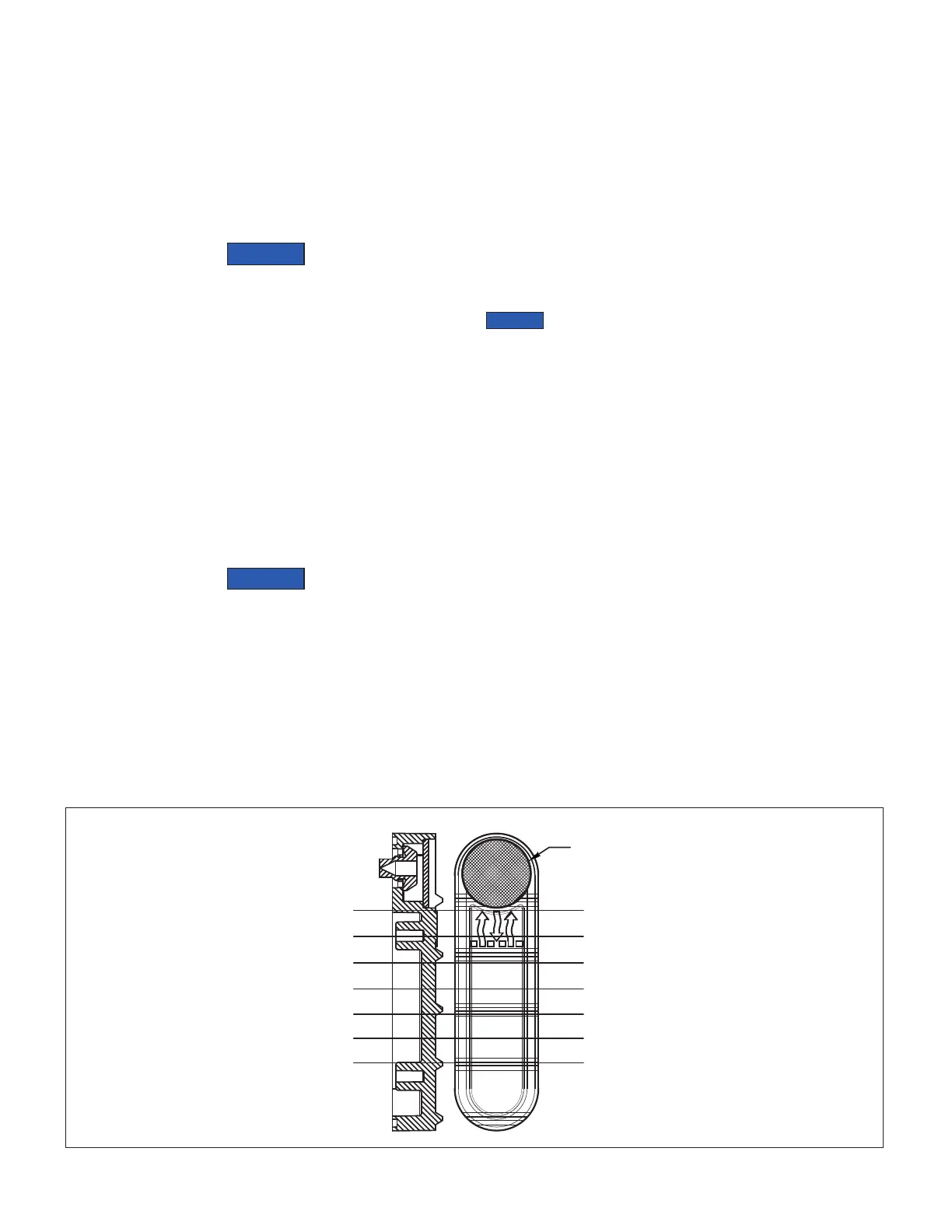

FULL (Up to bottom of air breather)

RESERVOIR AIR BREATHER

ADD 0.47 LITERS

ADD 0.95 LITERS

ADD 1.42 LITERS

ADD 1.89 LITERS

ADD 2.37 LITERS

ADD 2.84 LITERS - EMPTY

(Up to bottom of air breather) FULL

ADD 0.5 QUARTS

ADD 1.0 QUARTS

ADD 1.5 QUARTS

ADD 2.0 QUARTS

ADD 2.5 QUARTS

EMPTY - ADD 3.0 QUARTS

Figure 10, Reservoir Oil Fill Guide

Loading...

Loading...