Safety and operating instructions

52 © Construction Tools GmbH | 33905146 01 | 2019-09-05

Original Instructions

7.8 Checking the percussion

piston impact surface

n

Check the percussion piston impact surface when-

ever replacing the working tool, but at least once ev-

ery 100operating hours to make sure it is not

chipped and has no visible cracks.

n

Use an electric torch to illuminate the surface of the

dismantled working tool.

n

Do not use the hydraulic breaker again if you have

found the surface to be chipped or cracked.

n

Consult the Epiroc Customer Center / Dealer in your

area.

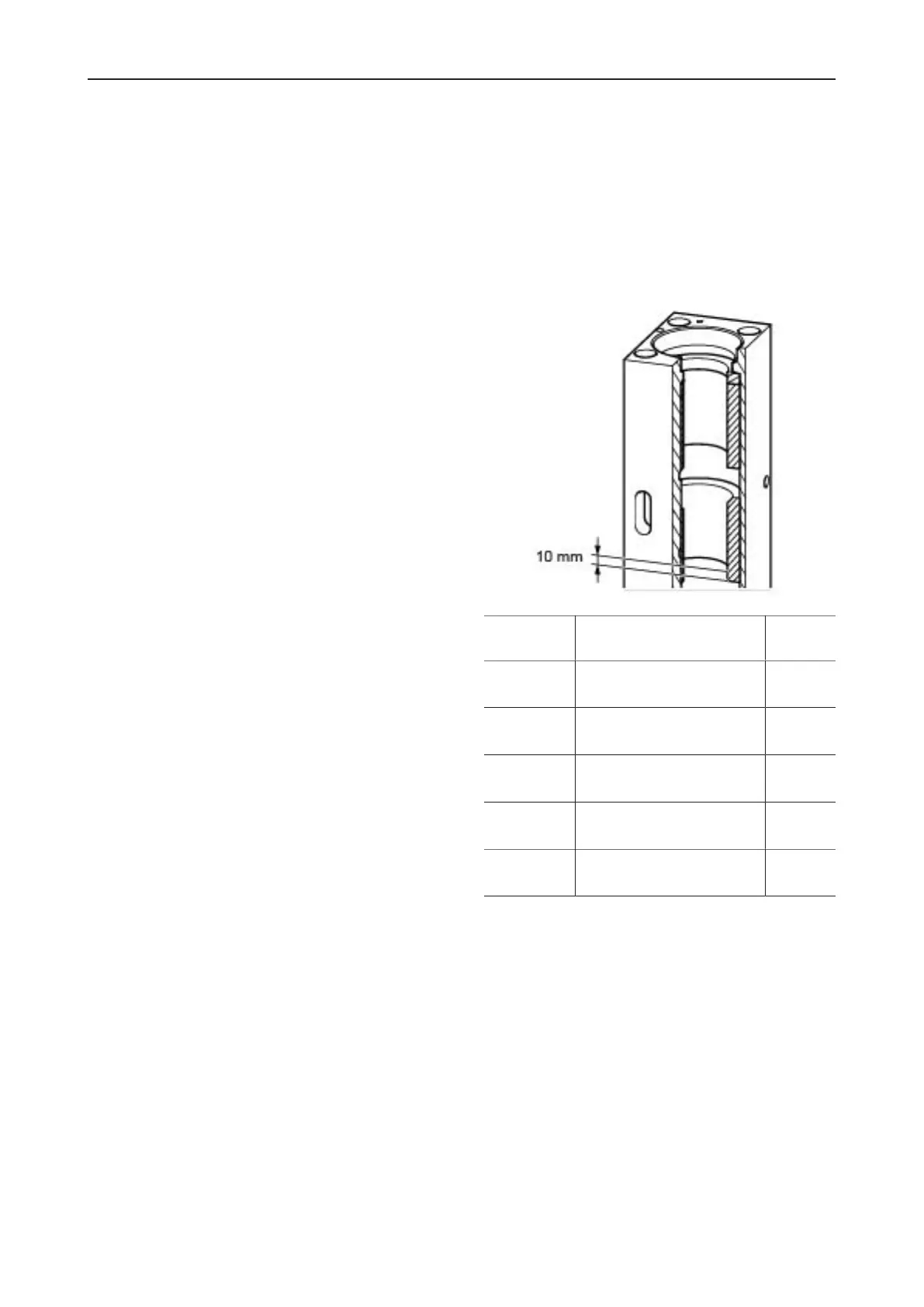

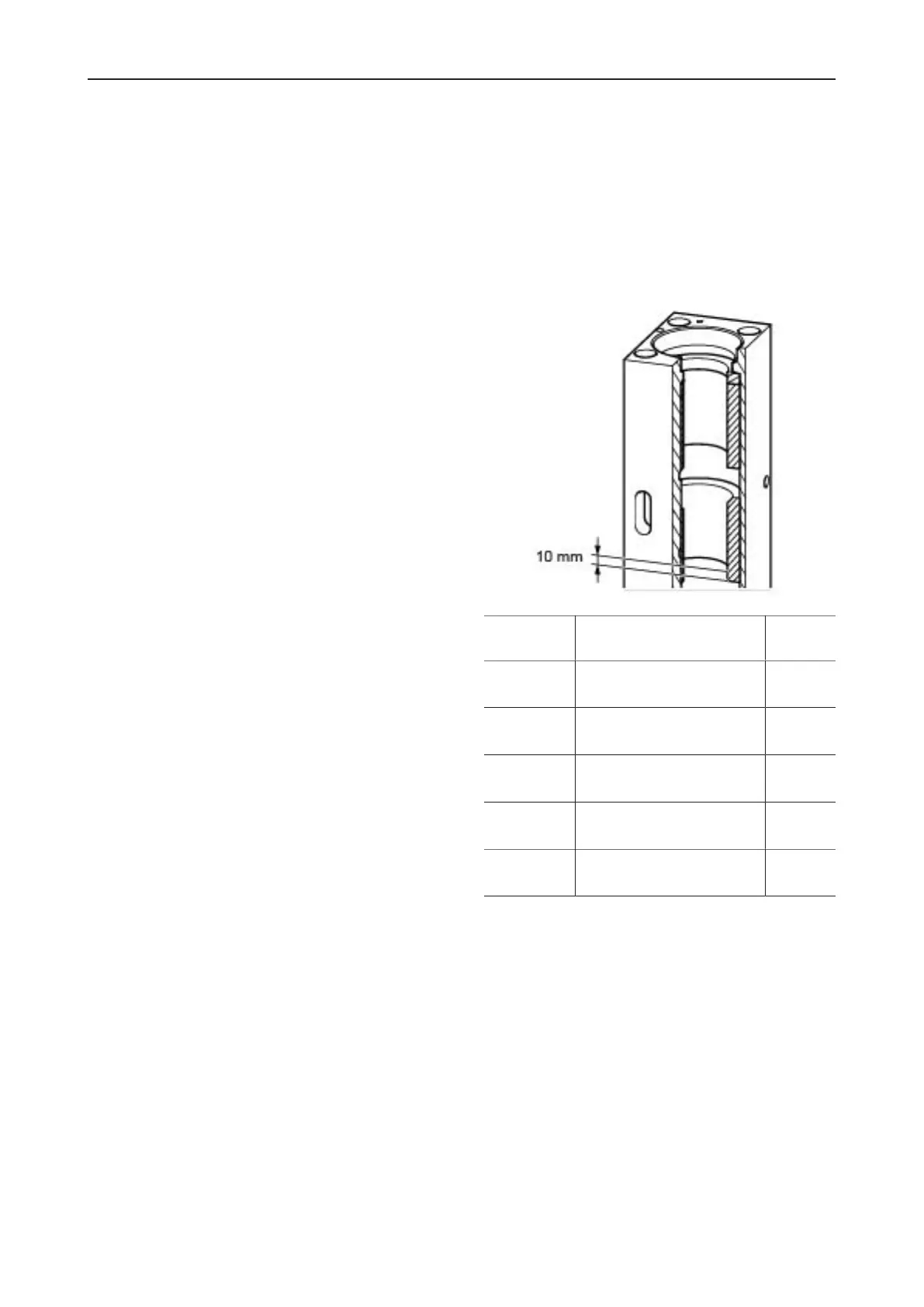

7.9 Checking the wear bushes

and impact ring

The wear bushes can be checked after removing the

working tool. You can check the diameter using the en-

closed test gauge. The diameter measured must not ex-

ceed the maximum permissible diameter D

max

(measur-

ing point see below).

Type Size information on test

gauge

D

max

EC 140T Ø140 (5.51in.) 145mm

(5.71in.)

EC 150T Ø150 (5.91in.) 155mm

(6.10in.)

EC 155T Ø155 (6.10in.) 160mm

(6.30in.)

EC 165T Ø165 (6.50in.) 170mm

(6.69in.)

EC 180T Ø180 (7.09in.) 185mm

(7.28in.)

n

Check the inside diameter of the lower and upper

wear bush whenever replacing the working tool, but

at least once every 100operating hours.

n

Clean the area around the impact ring to enable a

visual check.

The lower wear bush can be replaced on site. Consult

the Epiroc Customer Center / Dealer in your area.

n

Remove all remnants of lubricant from the inside of

the lower breaker part before installing new parts.

Loading...

Loading...