Safety and operating instructions

70 © Construction Tools GmbH | 33905146 01 | 2019-09-05

Original Instructions

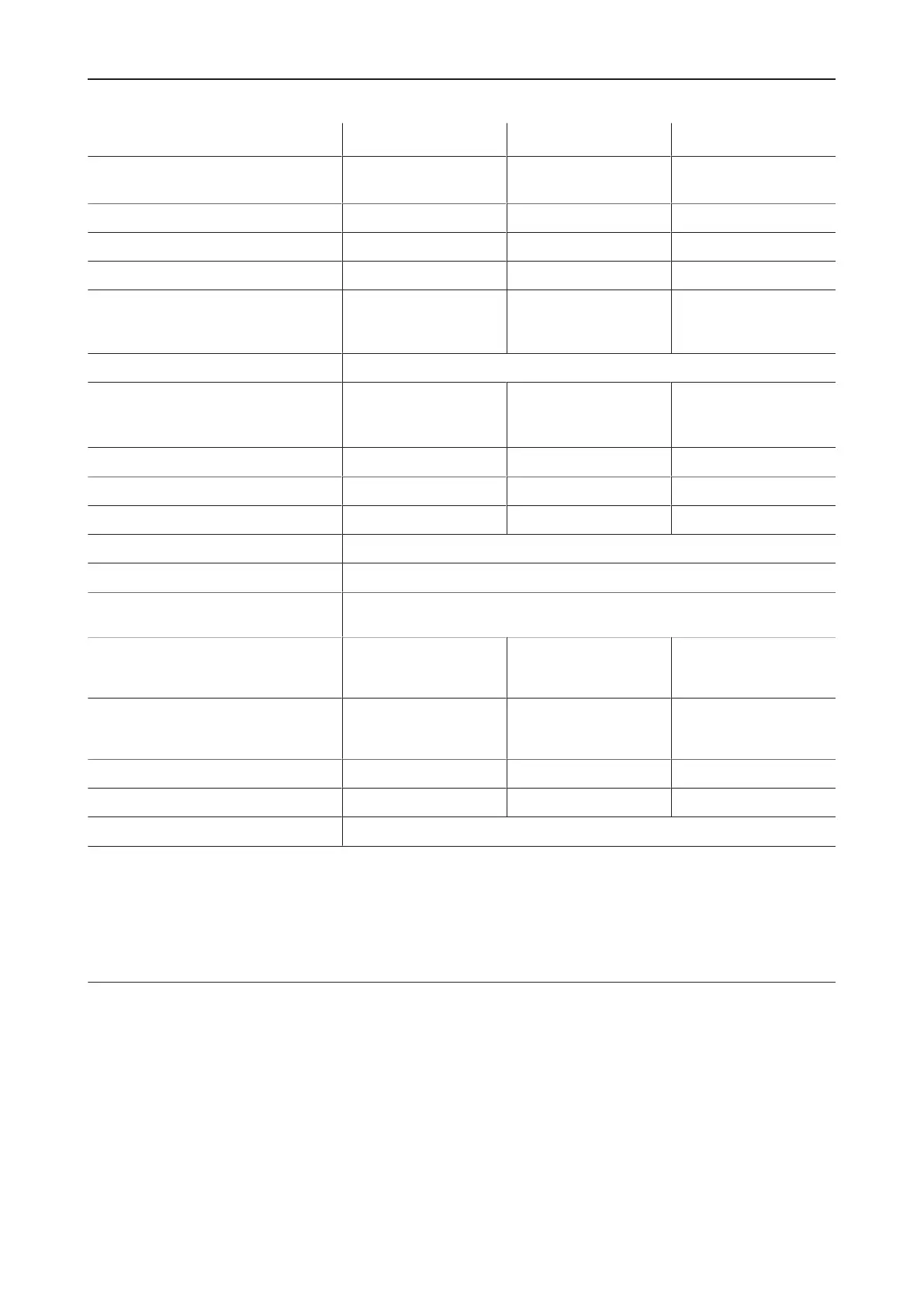

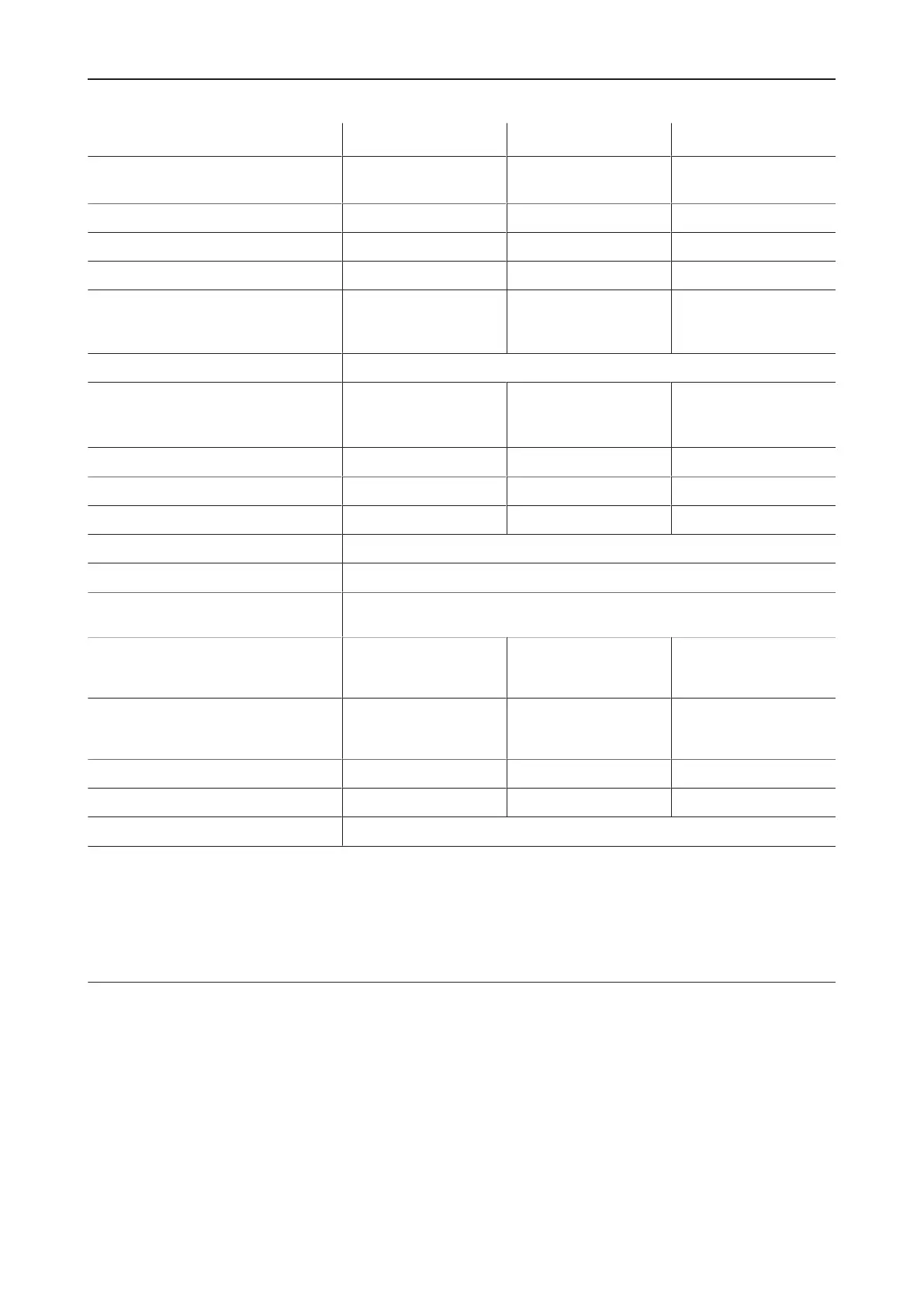

EC 155T EC 165T EC 180T

Carrier weight class

1)

30 - 45 t

(66100 - 99200 lbs)

35 - 55 t

(77200 - 121300 lbs)

45 - 70 t

(99000 - 154000 lbs)

Service weight

2)

2600 kg (5730 lbs) 3000 kg (6610 lbs) 4200 kg (9300 lbs)

Delivery weight

4)

2026 kg (4467 lbs) 2488 kg (5485 lbs) 3306 kg (7289 lbs)

Delivery weight

4)

(with ContiLube

®

II) 2032 kg (4480 lbs) 2494 kg (5498 lbs) 3312 kg (7302 lbs)

Oil flow rate 180 - 220 l/min

(47.6 - 58.1 gal (US)/

min)

220 - 270 l/min

(58.1 - 71.3 gal (US)/

min)

250 - 320 l/min

(66.0 - 84.5 gal (US)/

min)

Operating pressure 160 - 180 bar (2320 - 2610 psi)

Impact rate

Impact rate AutoStop

Impact rate AutoStart

adjustable

380 - 590 blows/min

530 - 800 blows/min

adjustable

380 - 580 blows/min

540 - 800 blows/min

adjustable

380 - 570 blows/min

550 - 800 blows/min

Working tool diameter 155 mm (6.11 in.) 165 mm (6.50 in.) 180 mm (7.09 in.)

Working length of working tool 655 mm (26 in.) 690 mm (27 in.) 765 mm (30 in.)

Max. hydraulic input power 66 kW (89 hp) 81 kW (109 hp) 96 kW (129 hp)

Back pressure acceptance

8)

30bar (435 psi)

Gas pressure HP-accumulator (20°C) 60 bar (870 psi)

Max. static pressure (pressure relief

valve on carrier)

200 bar (2900 psi)

Piston accumulator gas pressure

(min., at operating temperature

60-70°C)

7)

13.5 bar

(196 psi)

14.2 bar

(206 psi)

10.8 bar

(157 psi)

Piston accumulator gas pressure

(max. (optimum), at operating temper-

ature 60-70°C)

7)

16.0 bar

(232 psi)

16.7 bar

(242 psi)

13.3 bar

(193 psi)

Hose inside diameter »P« 25 mm (1 in.) 32 mm (1.3 in.) 32 mm (1.3 in.)

Hose inside diameter »T« 25 mm (1 in.) 32 mm (1.3 in.) 32 mm (1.3 in.)

Start up mode Stroke control

1)

Weights apply to standard carriers only. Any variances must be agreed with Epiroc and/or the carrier manufacturer

prior to attachment.

2)

Hydraulic breaker incl. breaker box, working tool, and adapter plate of medium size.

Please note that the service weight can be considerably higher, depending on the adapter plate.

4)

Hydraulic breaker, breaker box without working tool and adapter plate

7)

Hydraulic breaker in horizontal position, no pressure applied to working tool

8)

Back pressure acceptance when breaker still runs regular but at significant reduced performance (oil flow)

Loading...

Loading...