7

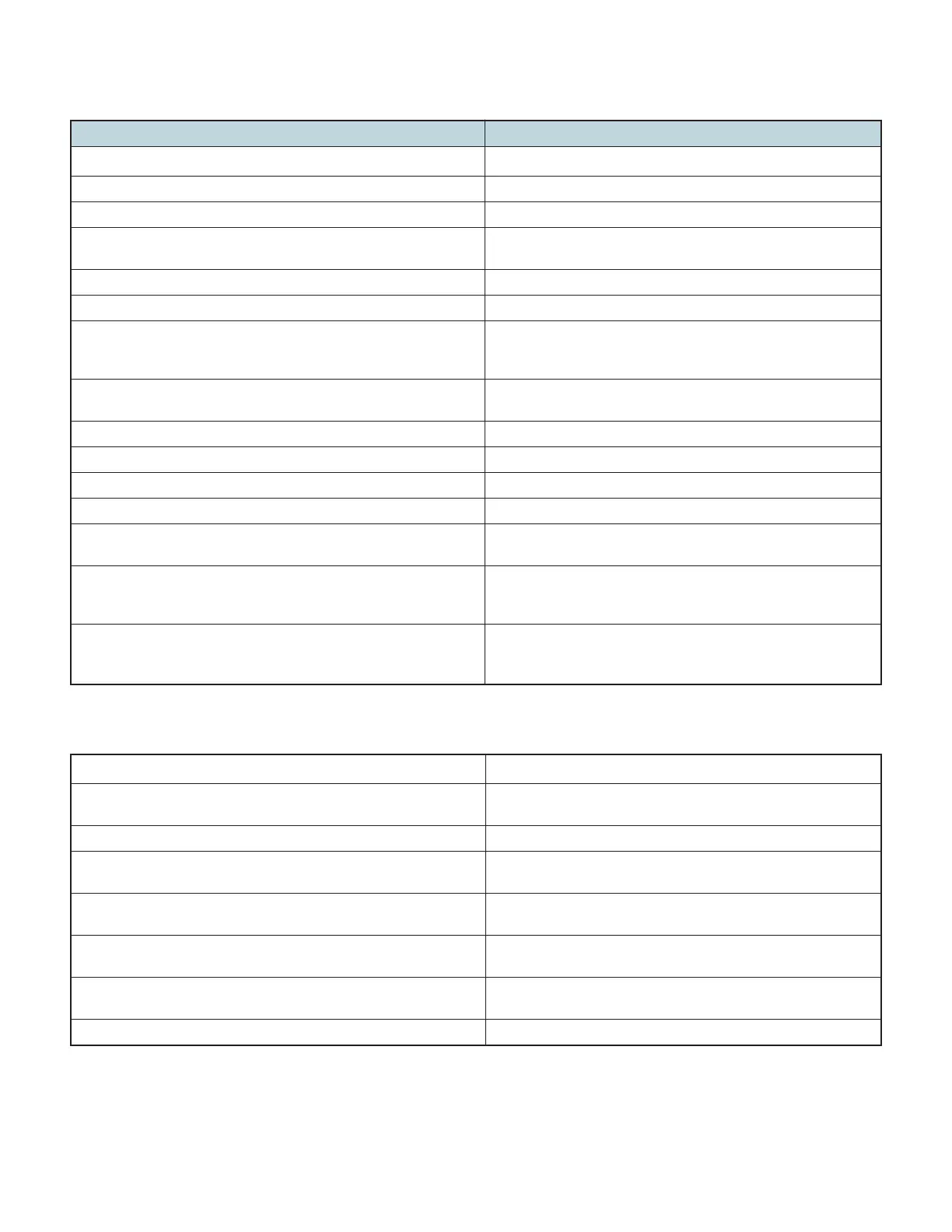

1. Gear Reducer – Check oil level with unit stopped 24 hours aer start-up & monthly

2. Gear Reducer/Piping – Do visual inspection for oil leaks, Monthly

auditory inspection for unusual noises and vibrations

3. Gear Reducer – Replace oil Semi-annually

4. Oil Pump – Do visual inspection for leaks and Monthly

proper wiring

5. Gear Reducer/Coupling – Check alignment of 24 hours aer start-up & monthly

the system

6. Coupling/Sha – Inspect flex elements and hardware Monthly

for tightness, proper torque & crack/deterioration

7. Heater Controller – Inspect controller and Quarterly

clean probe ends

8. Heater – Inspect junction box for loose wiring and moisture One month aer start-up and semi-annually

PROCEDURE

FREQUENCY

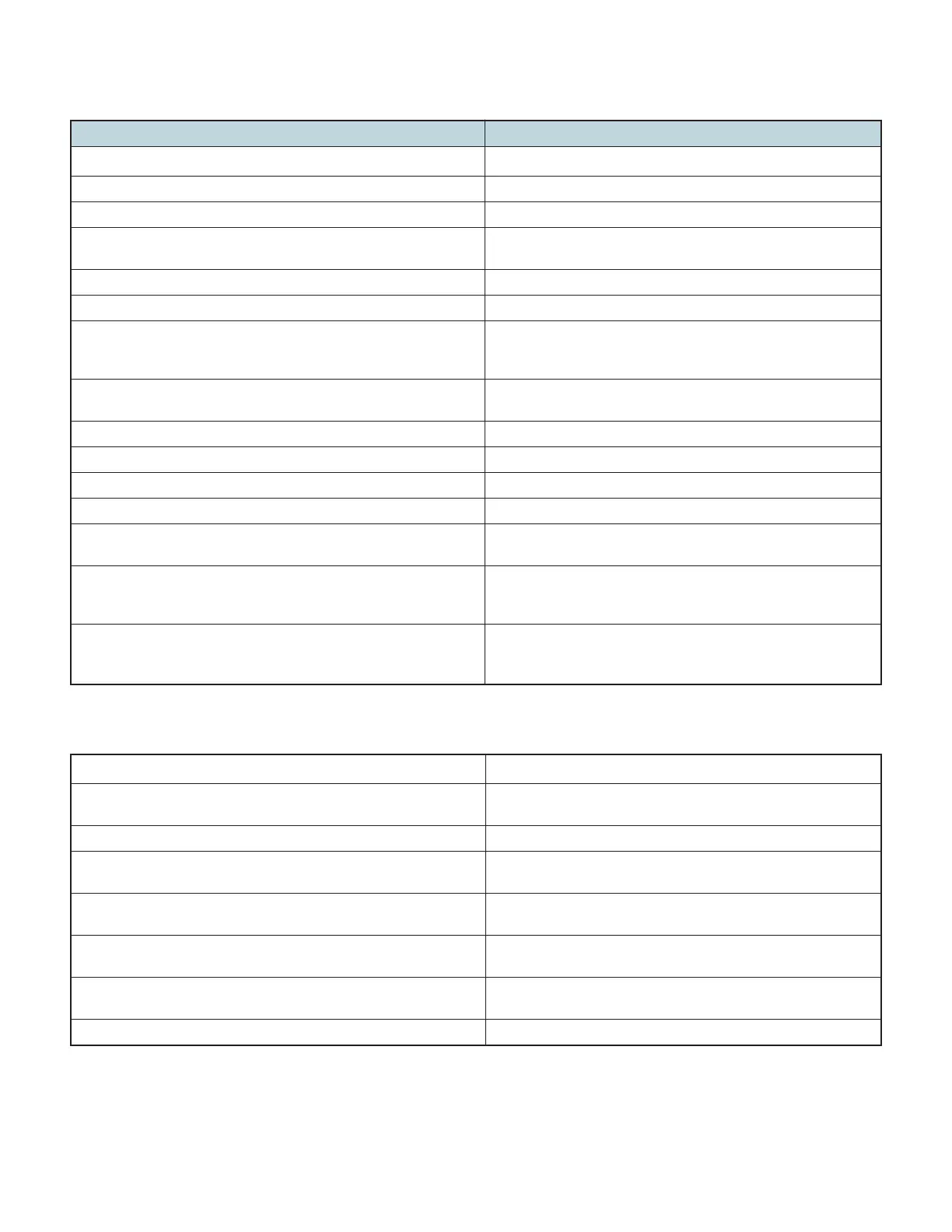

1. Clean pan strainer Monthly or as needed

2. Clean and flush pan** Quarterly or as needed

3. Check bleed-off valve to make sure it is operative Monthly

4. Check operating level in pan and adjust float valve Monthly

if necessary

5. Check water distribution system and spray pattern Monthly

6. Check dri eliminators Quarterly

7. Check the fan blades for cracks, missing balancing weights Quarterly

loose weight port caps and open drain holes

(Super Low Sound Fans) and vibrations

8. Check sheaves, bushings, fan shas and fan hubs Annually

for

corrosion. Scrape and coat with ZRC

9. Inspect lubrication lines to bearings Quarterly

10. Lubricate fan sha bearings* Every 1000 hours of operation (or every three months)

11. Check belt tension and adjust Monthly

12. Sliding motor base – Inspect and grease Annually or as needed

13. Check fan screens, inlet louvers and fans. Monthly or as needed

Remove any dirt or debris

14. Inspect and clean protective finish Annually

- Galvanized: scrape and coat with ZRC

- Stainless: clean and polish with a stainless steel cleaner.

15. Check water quality for biological contamination. Regularly

Clean unit as needed and contact a water treatment

company for recommended water treatment program**

OPTIONAL ACCESSORIES:

* See maintenance manual for start-up instructions and lubrication recommendations.

** Cooling Towers must be cleaned on a regular basis to prevent the growth of bacteria including Legionella Pneumophila.

R

ecommended Minimum Maintenance Schedule

Loading...

Loading...