8

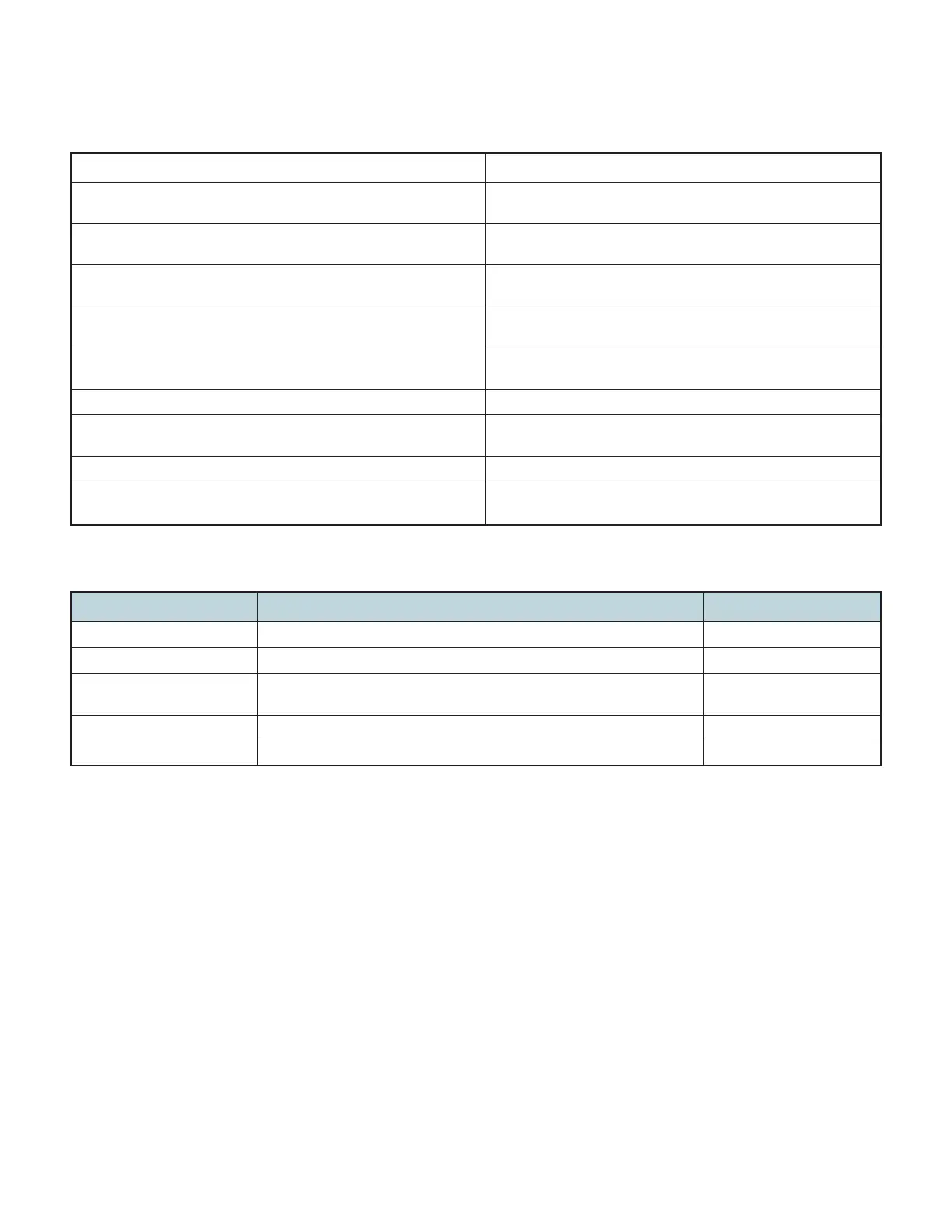

9. Heater – Inspect elements for scale build-up Quarterly

10. Electronic Water Level Controller – Inspect junction box Semi-annually

for loose wiring and moisture

11. Electronic Water Level Controller – Clean probe ends Quarterly or as needed

of scale build-up

1

2. Electronic Water Level Controller – Clean inside Annually

the standpipe

13. Solenoid Make-up Valve – Inspect and clean valve and As needed

strainer of debris

14. Vibration Switch (mechanical) – Inspect enclosure for One month aer start-up and monthly

loose wiring and moisture

15. Vibration Switch – Adjust the sensitivity During start-up and annually

16. Sump Sweeper Piping – Inspect and clean piping Semi-annually

of debris

17. Water Level Indicator – Inspect and clean Annually

18. SUN Solar Panels – Inspect for damage and clean with Semi-annually

hose and so brush

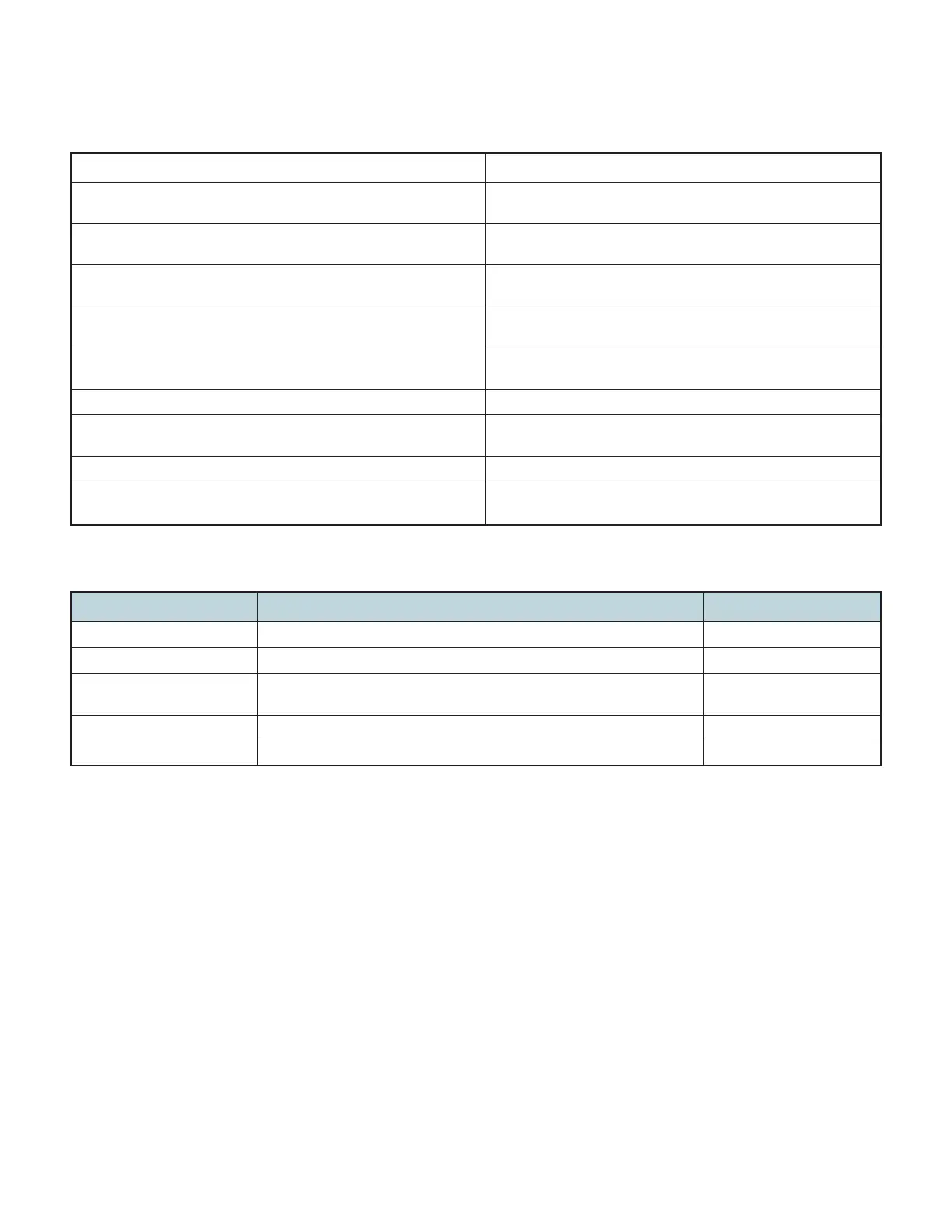

Idle Period Recommended Action Frequency

Two or More Days Energize motor space heaters

-or run motors for 10 minutes Twice daily

Few Weeks Run gear reducer for 5 minutes Weekly

Several Weeks

Completely fill gear reducer with oil.

Once

Drain to normal level prior to running.

One Month or Longer

Rotate motor sha/fan 10 turns Bi-weekly

Megger test motor windings Semi-annually

R

ecommended Maintenance Schedule

(continued)

OPTIONAL ACCESSORIES:

DURING IDLE PERIODS:

Loading...

Loading...