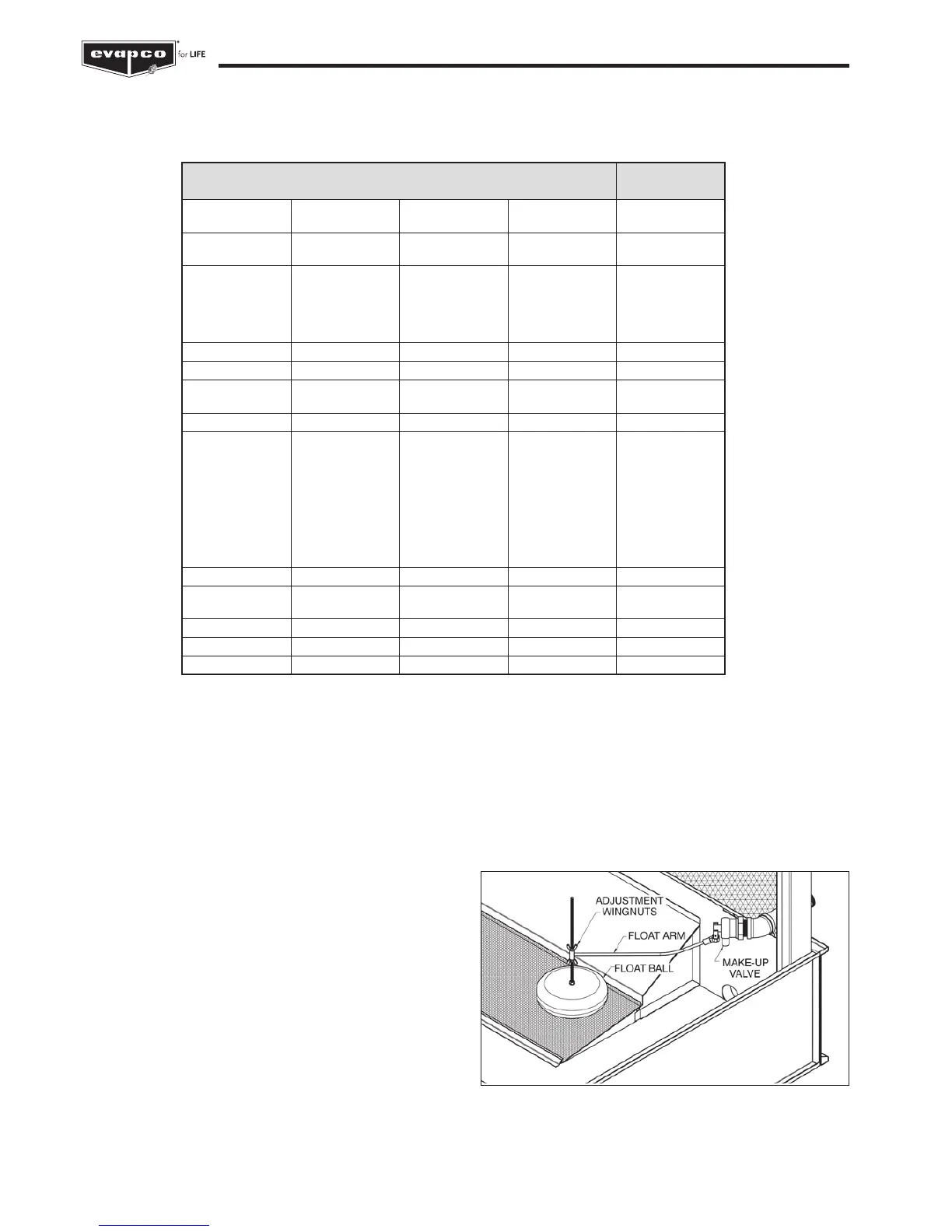

Operating Level of Water in Cold Water Basin

The operating level should be checked monthly to make sure the water level is correct. Refer to Table 3 for unit specific levels.

At initial start up or after the unit has been drained, the unit must be filled to the overflow level. Overflow is above the normal

operating level and accommodates the volume of water normally in suspension in the water distribution system and the riser piping.

The water level should always be above the strainer. Check by running the pump with the fan motors off and observing the water

level through the access door or remove the air inlet louver.

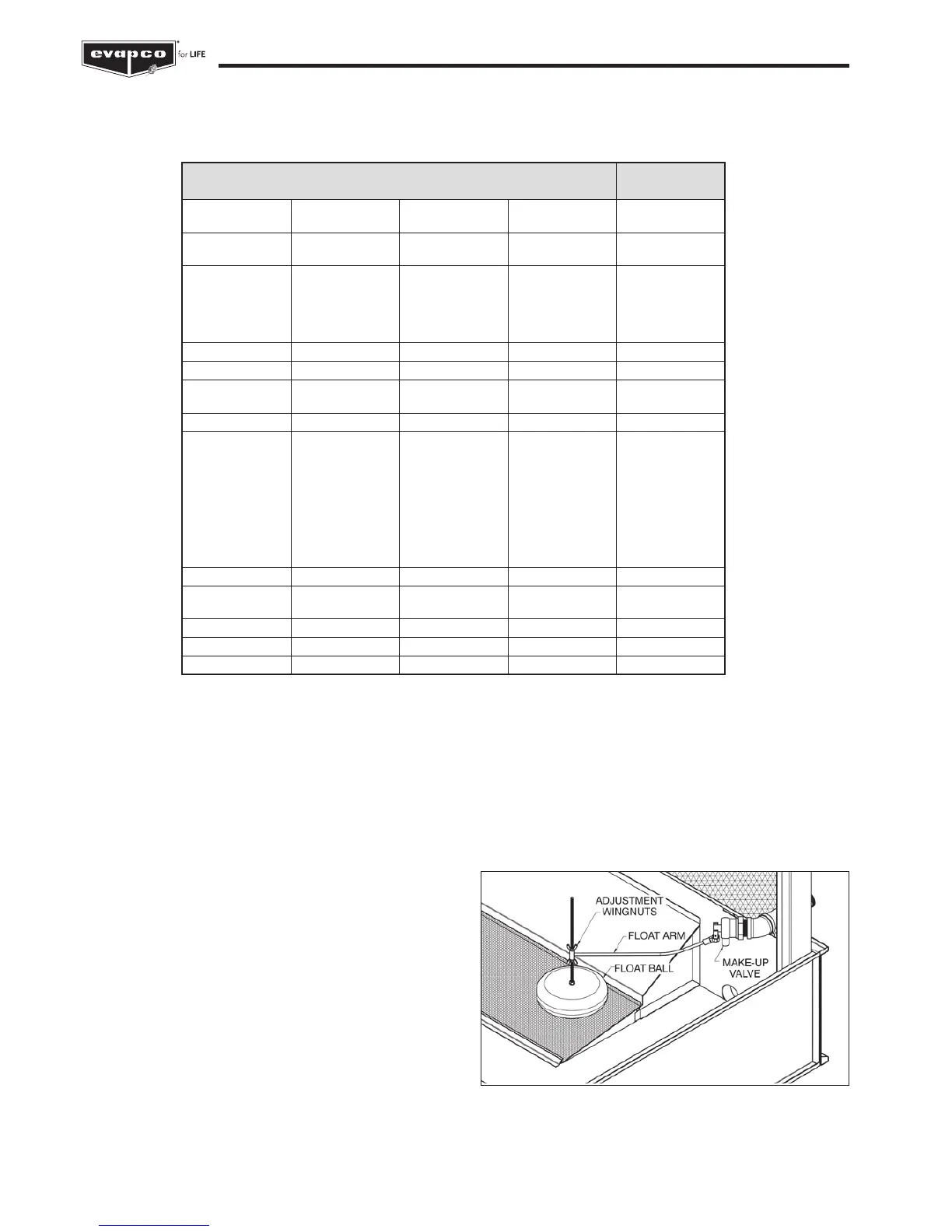

Water Make Up Valve

A mechanical float valve assembly is provided as standard

equipment on the evaporative cooling unit (unless the unit has

been ordered with an optional electronic water level control

package or the unit is arranged for remote sump operation). The

make up valve is easily accessible from outside the unit through

the access door or removable air inlet louver. The make up valve

is a bronze valve connected to a float arm assembly and is

activated by a large foam filled plastic float. The float is mounted

on an all-thread rod held in place by wing nuts. The water level

in the basin is adjusted by repositioning the float and all-thread

using the wing nuts. Refer to Figure 12 for details.

The make up valve assembly should be inspected monthly and

adjusted as required. The valve should be inspected annually

for leakage and if necessary, the valve seat should be replaced.

The make up water pressure for the mechanical valve should be

maintained between 140 and 340 kPa.

* Measured from lowest point on basin floor.

Table 3 - Recommended Operating Water Level

Figure 12 – Mechanical Water Make Up Valve

Model Number Operating

Level

ATW

ATW

9

64

through

through

48

866

230 mm

280 mm

ESWA

ESWA

72

144

through

through

142

216

280 mm

280 mm

LSWA

LSWA

LSWA

LSWA

LSWA

20

91

116

135

174

through

and

and

and

and

87

182

232

270

348

280 mm

300 mm

300 mm

380 mm

380 mm

LRW 18 through 379 200 mm

C-ATW 67-3H through 133-6J 280 mm

eco-ATW

eco-ATW

0,9 m wide

2,3 m wide

and

through

1,2 m wide

7,3 m wide

230 mm

280 mm

eco-ATWE 2,3 m wide through 7,3 m wide 280 mm

LSCE

LSCE

LSCE

LSCE

LSCE

LSCE

LSCE

LSCE

LSCE

36

281

591

400

800

410

820

550

1100

through

through

through

through

through

through

through

through

through

385

386

770

515

1030

560

1120

805

1610

280 mm

300 mm

300 mm

300 mm

300 mm

380 mm

380 mm

380 mm

380 mm

LRC 25 through 379 200 mm

ATC

ATC

50E

M170E

through

through

165E

3714E

230 mm

280 mm

C-ATC 181 through 504 280 mm

PMCQ 316 through 1786 360 mm

eco-ATC 176 through 4086 280 mm

Loading...

Loading...