WARNING: Sound reducing options are available. In case these options are not taken in consideration, the customer

must design the installation to comply with local sound requirements and legislation.

WARNING: In order to avoid excessive pressure, proper safety valves should be foreseen in the cooling installation.

These safety measures are not delivered by Evapco and are the responsibility of the customer/contractor.

The application of these safety measures has to be evaluated for the cooling system as a whole and not

limited to the partly completed machinery.

WARNING: Atmospheric corrosion and corrosion due to the use of corrosive media at the inside/or outside of the

coils is forbidden and voids the PED certification.

WARNING: Every handling that effects the integrity of the pressure vessel (example, but not limited to, welding,

grinding, drilling, ... ) is forbidden and voids the PED certification.

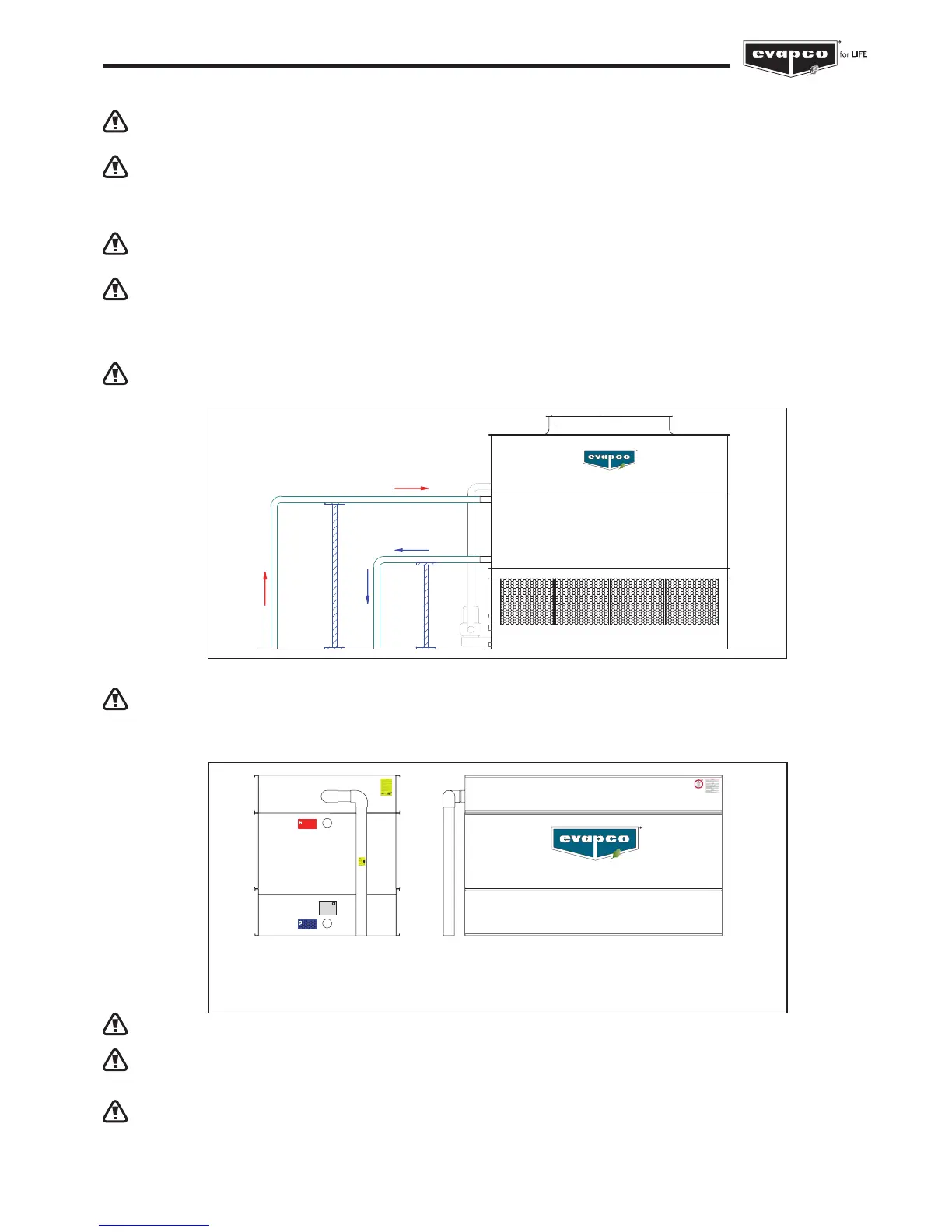

Installation Precautions

WARNING: The coil connections are not designed to support piping. The water / glycol / refrigerant piping always

need to be supported (by others). See also Bulletin 131-E “Piping Evaporative Condensers”.

Storage Precautions

WARNING: Never use plastic sheets or tarps to protect a unit during storage. This practice can trap heat inside the

unit and could potentially cause damage to plastic components.

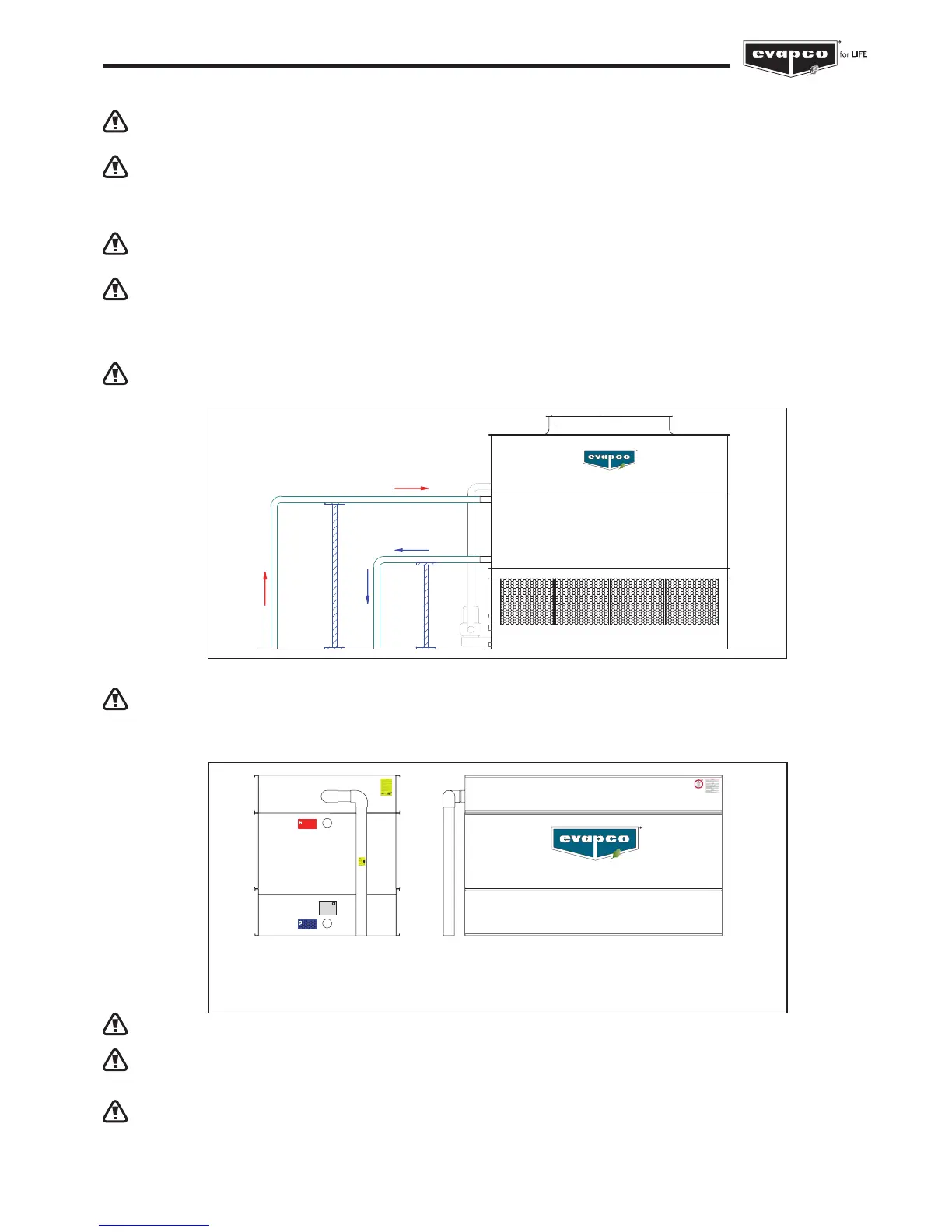

Label on the coil section(s)

WARNING: Do not operate the pressure vessel at service conditions outside of the PED nameplate located

at the coil connection. See position 1 for the location of the PED nameplate.

WARNING: Maximum working temperature of the pressure vessel as mentioned on the PED nameplate exceeds

the nominal operating temperature of the unit. Never apply pressure vessel temperatures above 65°C

or consult the factory for approval.

WARNING: Legal periodic controls of the pressure vessel need to be performed according to the legal requirements

of the country.

TEST bar DATE

PRESSURE

TEMPERATURE -10°C / +120°C

WORKING

DESIGN TEMPERATURE -20°C / +140°C

FLUID

VOLUME

INDUSTRIETERREIN OOST 4010

EUROPE N.V.EVAPCO

DWG.

S.N.

MODEL

YEAR

0036

BELGIUM

B-3700 TONGEREN

MAX WORKING PRESSURE bar

FLUID OUT

SORTIE DU FLUIDE

FLUESSIGKEIT AUS

USCITA FLUIDO

12A

FLUID IN

ENTREE DU FLUIDE

FLUESSIGKEIT EIN

ENTRATA FLUIDO

11A

2A

(2)

2 (2)

35

17A

1

12A

11A

34

1.

PED NAMEPLATE/SERVICE CONDITIONS

2. EVAPCO LOGO (both sides)

2A. RIGGING INSTRUCTIONS (both ends)

11A. FLUID IN

12A. FLUID OUT

17A. WARNING ELIMINATORS

34. WARNING PVC PIPE

35. DO NOT COVER ELIMINATORS

Loading...

Loading...