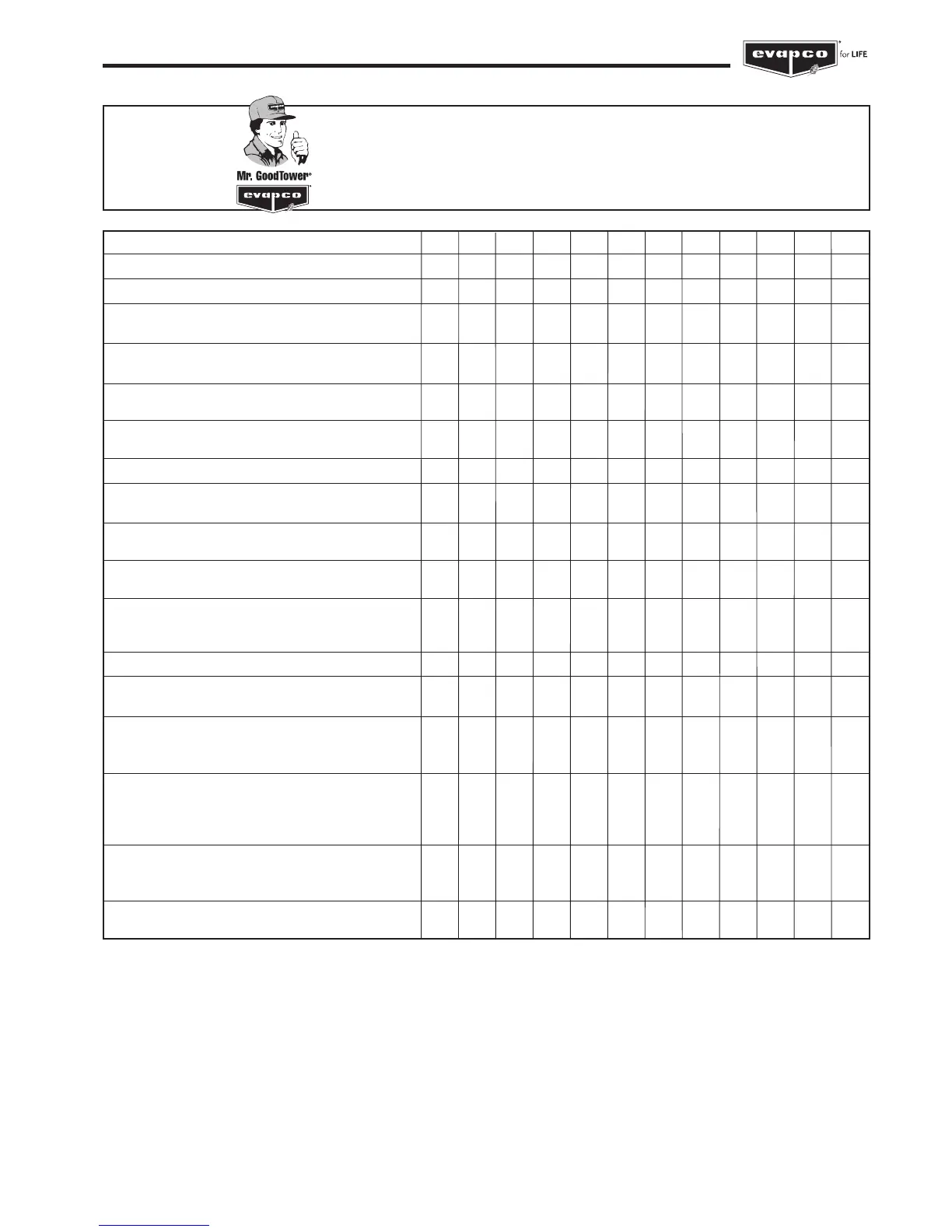

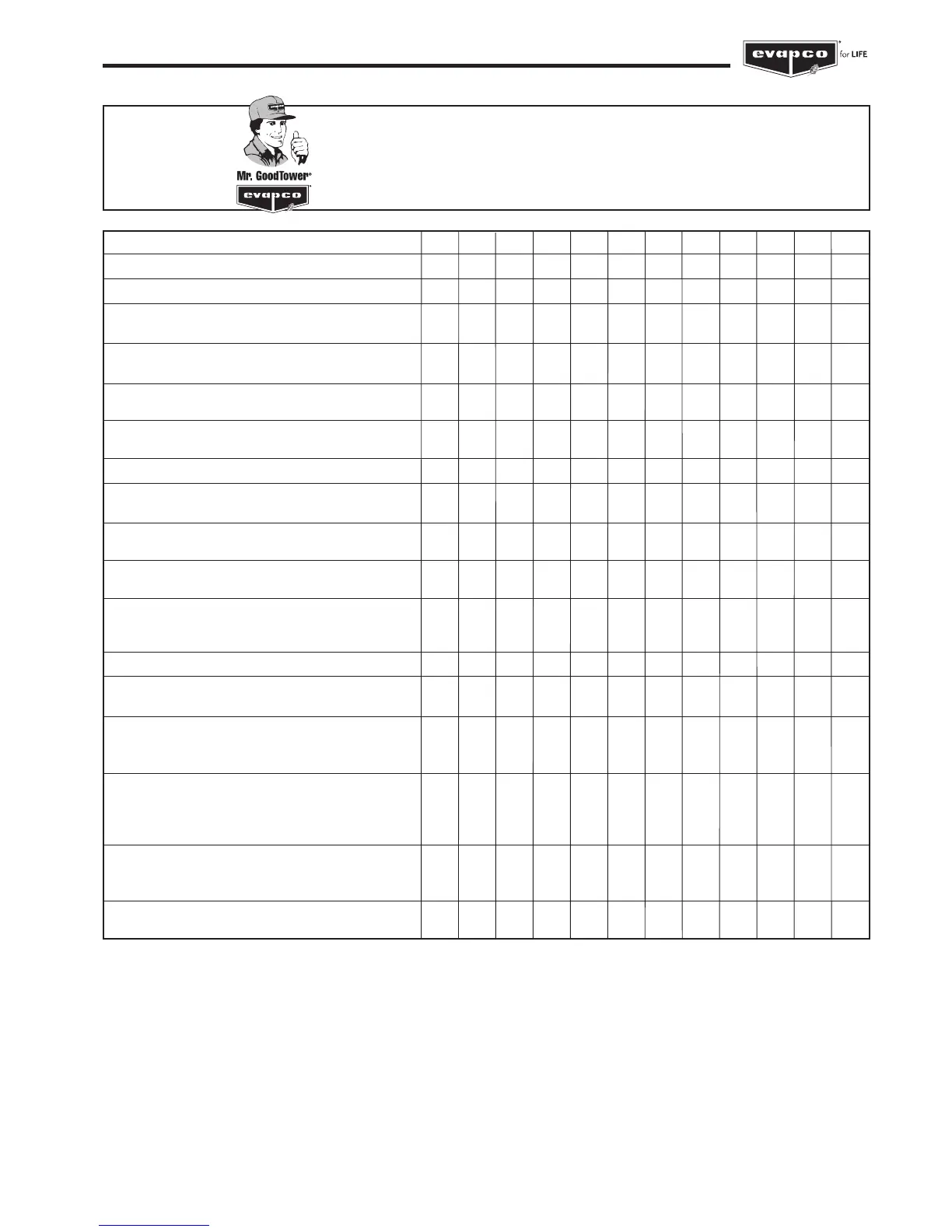

PROCEDURE

1. Clean pan strainer - monthly or as needed

2. Clean and flush pan* - quarterly or as needed

3. Check bleed-off valve to make sure it is

operative - monthly

4. Lubricate pump and pump motor according to

manufacturer’s instructions

5. Check operating level in pan and adjust float

valve if necessary - monthly

6. Check water distribution system and spray

pattern - monthly

7. Check drift eliminators - quarterly

8. Check the fan blades for cracks, missing

balancing weights, and vibrations - quarterly

9. Check sheaves and bushings for corrosion.

Scrape and coat with ZRC - annually

10. Lubricate fan shaft bearings - every 1000

hours of operation or every three months

11. Lubricate fan motor bearings - see mfg’s

instructions. Typically for non-sealed bearings,

every 2-3 years

12. Check belt tension and adjust - monthly

13. Inspect and grease sliding motor base -

annually or as needed

14. Check fan screens, inlet louvers, fans and

(dry) cooler coil. Remove any dirt or debris –

monthly

15. Inspect and clean protective finish - annually

- Galvanized: scrape and coat with ZRC

- Stainless: clean and polish with a

stainless steel cleaner.

16. Check water quality for biological contamination.

Clean unit as needed and contact a water

treatment company.

17. Check coil surface for scale and/or corrosion -

every 6 months

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

MAINTENANCE CHECKLIST

* Evaporative Cooling Equipment must be cleaned on a regular basis to prevent the growth of bacteria including Legionella Pneumophila.

Loading...

Loading...