10

Fan Shaft Sleeve Bearings – (1,2 m wide LSTE units only)

Lubricate the intermediate sleeve bearing(s) before unit start up. The reservoir should be checked

severaltimesduringtherstweektoensurethattheoilreserveisbroughttofullcapacity.After

therstweekofoperation,lubricatethebearing(s)every1.000hoursofoperationorevery

threemonths(whicheveroccursrst).Hightemperaturesorpoorenvironmentalconditionsmay

necessitate more frequent lubrication. The oil reservoir consists of a large felt packed cavity within

thebearinghousing.Itisnotnecessarytomaintaintheoillevelwithinthellercup.

Use one of the following industrial grade, non-detergent mineral oils. Do not use a detergent

based oil or those designated heavy duty or compounded. Different oils may be required

when operating at temperatures below -1°C continuously. Table 2 provides a short list of approved

lubricants for each temperature range. Most automotive oils are detergent based and may not be

used. Detergent oils will remove the graphite in the bearing sleeve and cause bearing failure.

Ambient Temp. Texaco Mobil Exxon Total

-32°C to 0°C - DTE Heavy - -

-17°C to 43°C - - - -

0 to 38°C Regal R&O 220 DTE Oil BB Teresstic 220 -

Table 2 - Sleeve Bearing Lubricants

Oil drippage may result from over-oiling or from using too light an oil. Should this condition persist

with correct oiling, it is recommended that the next heavier weight oil be used.

All bearings used on EVAPCO equipment are factory adjusted and self aligning. Do not disturb

bearing alignment by tightening the sleeve bearing caps.

Fan Belt Adjustment

Thefanbelttensionshouldbecheckedatstartupandagainaftertherst24hoursofoperation

to correct for any initial stretch. To properly adjust the belt tension, position the fan motor so that

thefanbeltwilldeectapproximately13mmwhenmoderatepressureisappliedmidwaybetween

the sheaves.

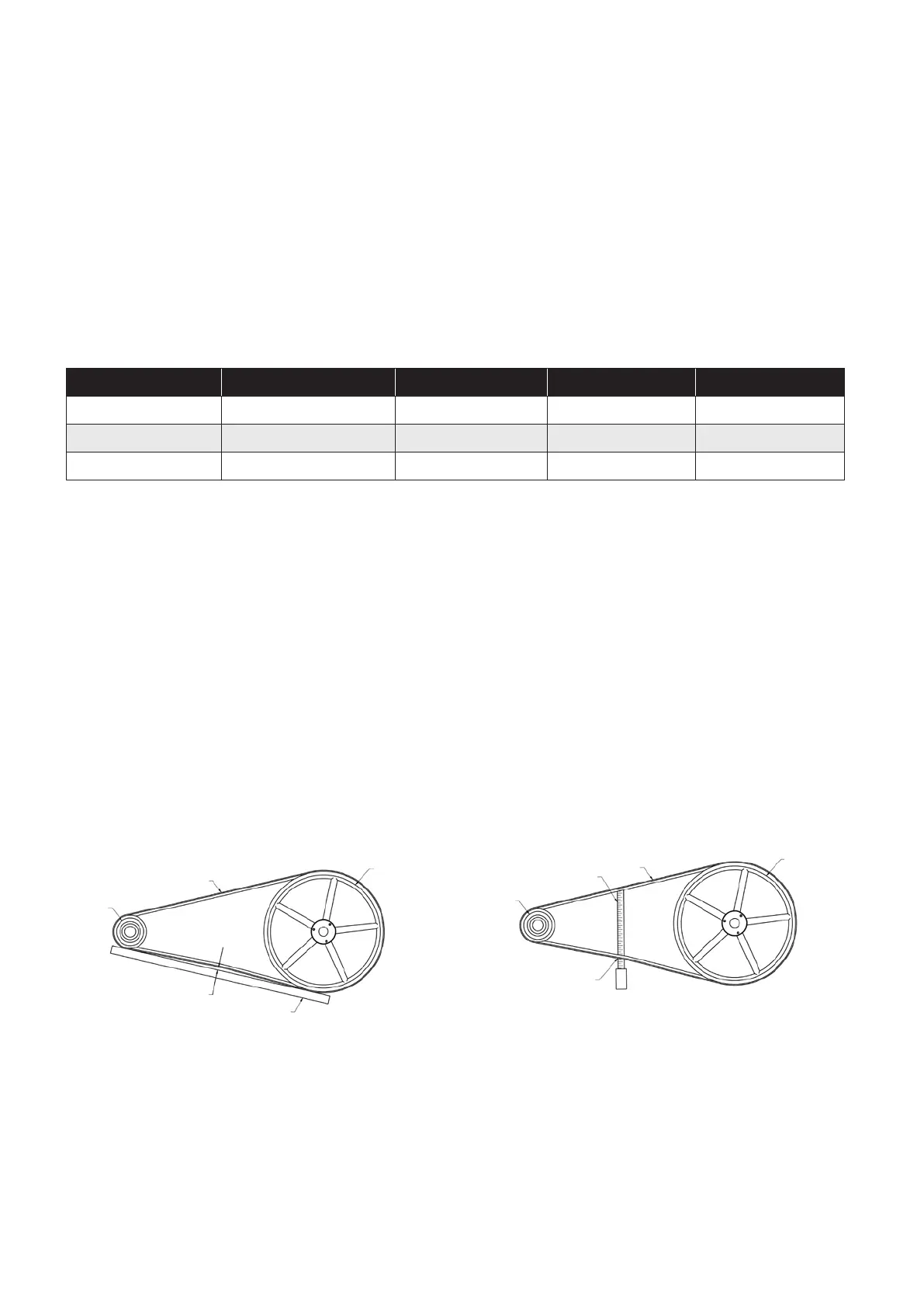

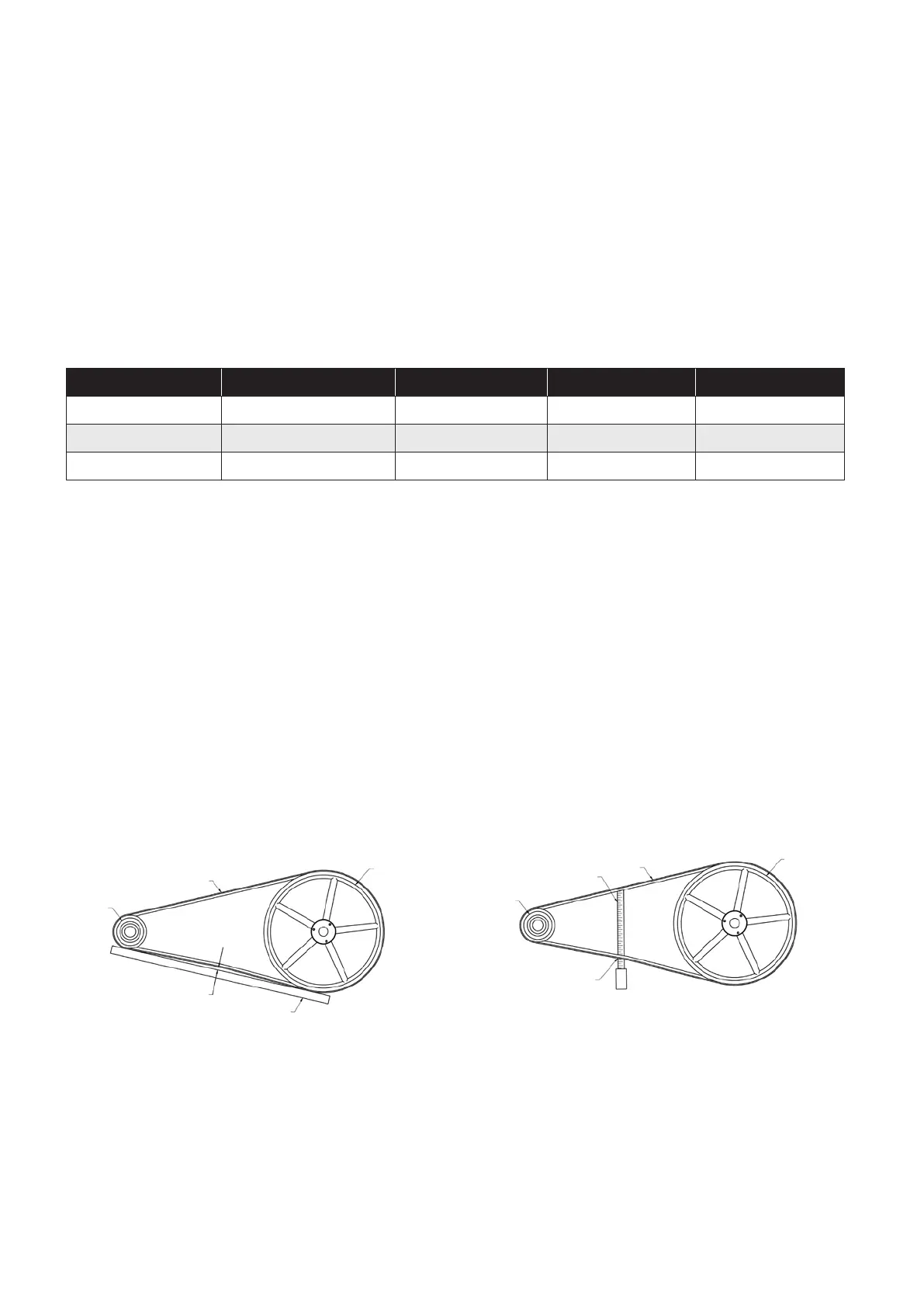

Figure1andFigure2showtwowaystomeasurethisdeection.Belttensionshouldbecheckedon

a monthly basis. A properly tensioned belt will not “chirp” or “squeal” when the fan motor is started.

Figure 1 – Method 1 Figure 2 – Method 2

BELT

DRIVER

SHEAVE

DRIVEN

SHEAVE

STRAIGHT EDGE

13 mm DEFLECTION =

PROPER BELT TENSION

BELT

DRIVER

SHEAVE

DRIVEN

SHEAVE

TAPE MEASURE

13 mm DEFLECTION =

PROPER BELT TENSION

Loading...

Loading...