25

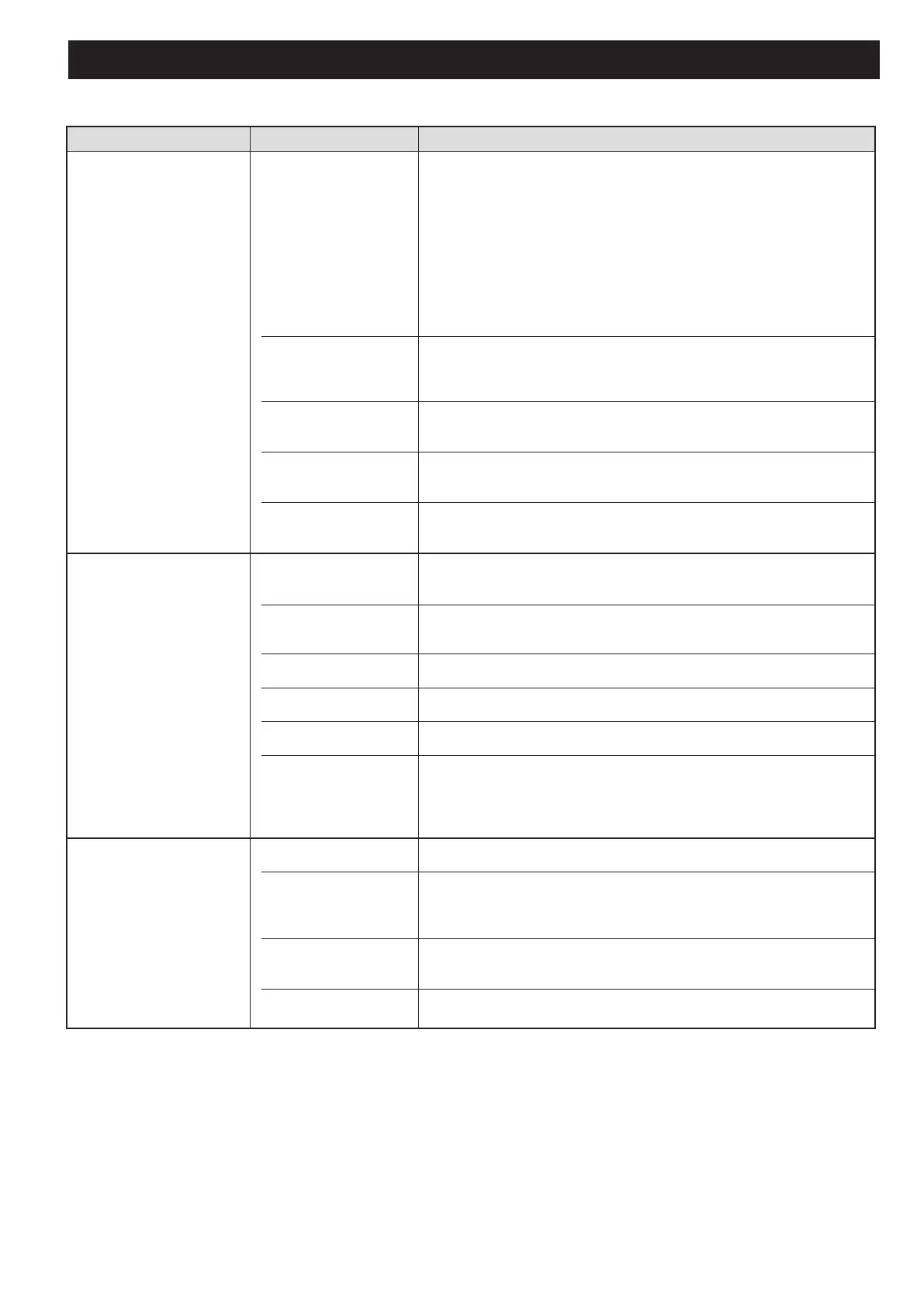

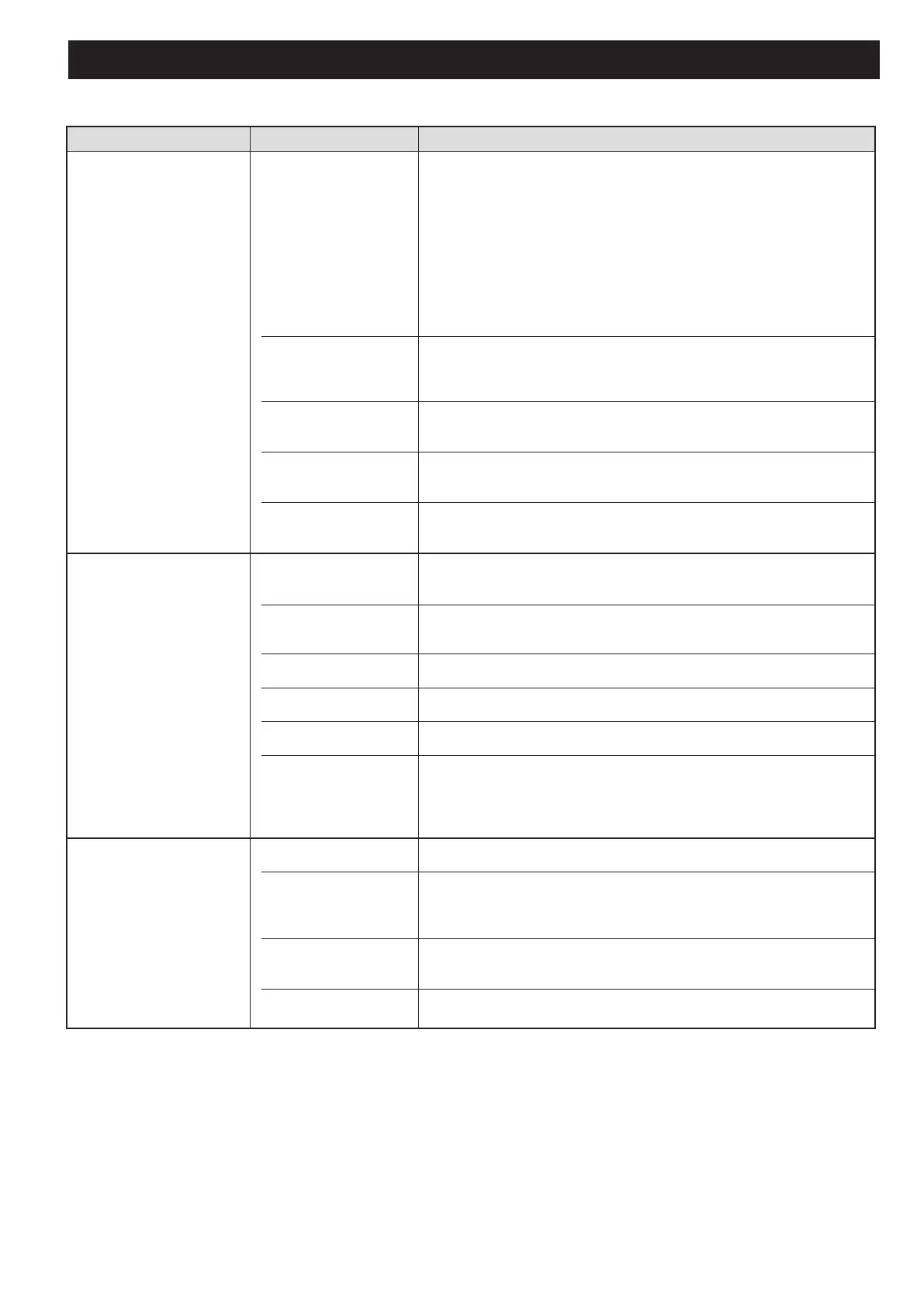

Troubleshooting

Problem Possible Cause Remedy

Reduction in air static

pressure

Electrical issue

Fan rotation

Mechanical failure

Belt tension

Motor running single-

phase

Motor leads connected

incorrectly

Bad bearings

Electrical unbalance

Air gap not uniform

Rotor unbalance

Cooling fan hitting end

bell guard

Nozzles clogged

Pump running

backwards (remote

sump)

Inadequate pump flow

for remote sump

Strainer clogged

1. On a forced draft unit verify that the pump is on, and water is

flowing over the coil. If the pump is off, and the unit was not sized

for dry operation, the motor may over-amp.

2. If the forced draft unit is ducted, verify that the design ESP

matches the actual ESP.

3. Verify the correct pump rotation direction. If the pump is rotating

incorrectly, it will result in less water flow, and therefore less overall

static pressure.

4. Check the basin water level against the recommended level.

Note: Air density directly affects AMP reading.

1. Check voltage across all three legs of the motor.

2. Verify that the motor is wired per the wiring diagram, and

connections are tight.

Verify that the fan is rotating in the correct direction. If not, switch the

leads so it runs correctly.

Verify that the fan and motor turn freely by hand. If not, there may be

damage to the internal motor components or bearings.

Check for proper belt tension. Extreme belt tension can cause the

motor to overamp.

Stop motor and attempt to start it. Motor will not start again if single

phased. Check wiring, controls and motor.

Check motor connections against wiring diagram on motor.

Check lubrication. Replace bad bearings.

Check voltage and current of all three lines. Correct if required.

Check and correct bracket fits or bearing.

Rebalance.

Reinstall or replace fan.

Remove nozzles and clean. Flush water distribution system.

Visually verify pump rotor rotation by turning pump off and then on.

Verify amp draw.

Confirm inlet pressure at header meets recommended valves.

Remove strainer and clean

Overamping Fan Motors

Unusual Motor Noise

Incomplete Spray

Pattern

Loading...

Loading...