15

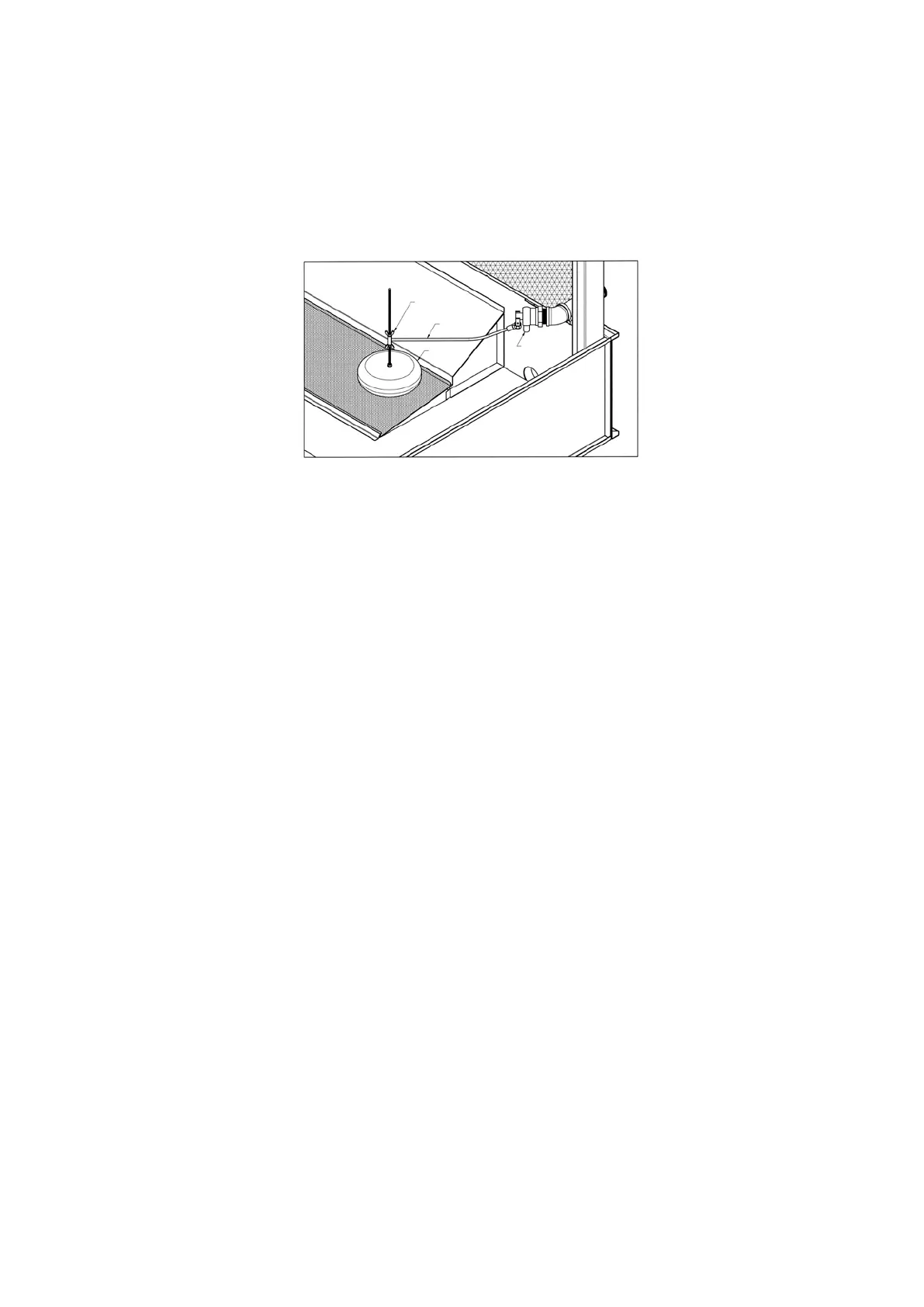

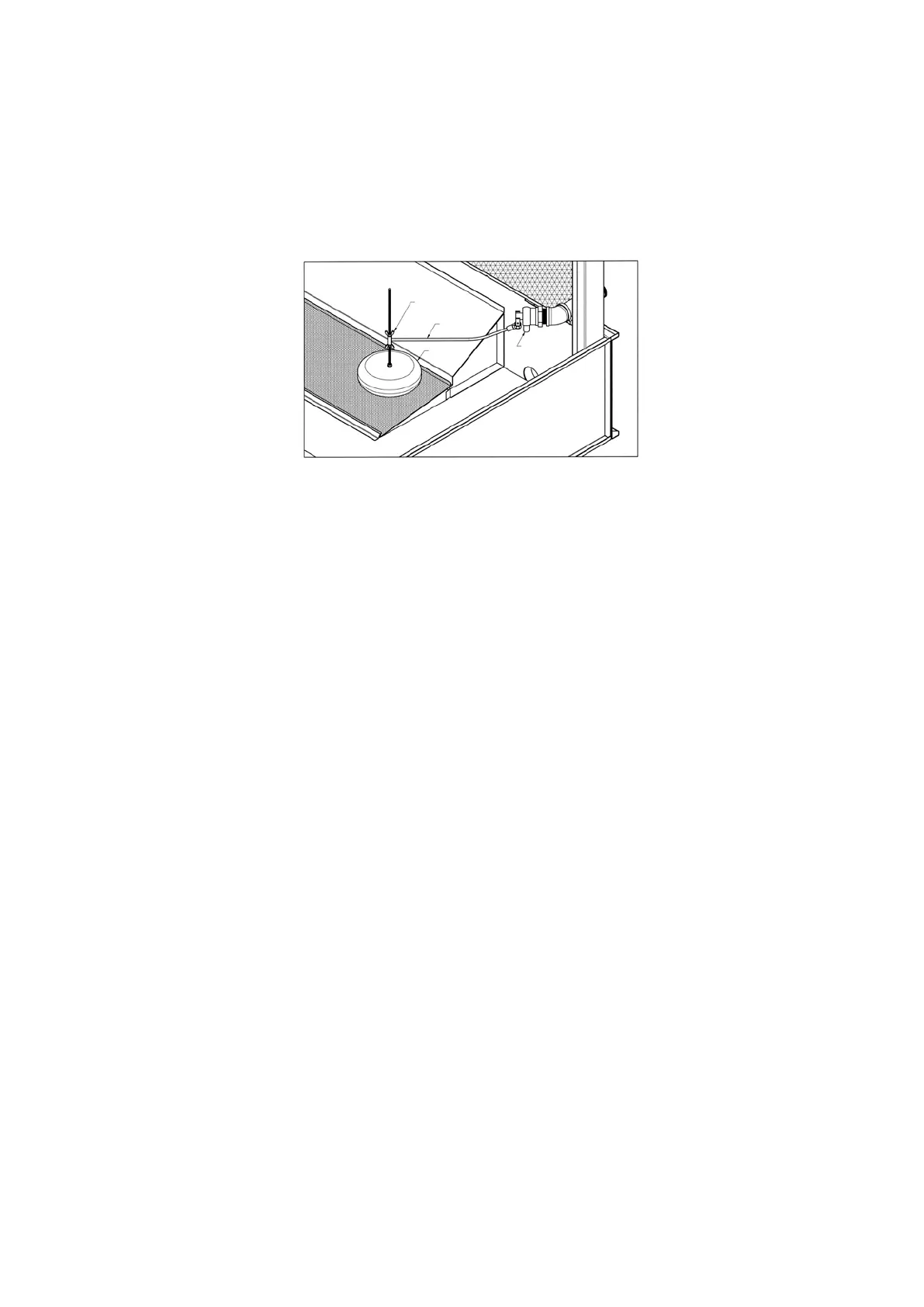

Water Make Up Valve

Amechanicaloatvalveassemblyisprovidedasstandardequipmentontheevaporativecooling

unit (unless the unit has been ordered with an optional electronic water level control package

or the unit is arranged for remote sump operation). The make up valve is easily accessible from

outside the unit through the access door or removable air inlet louver. The make up valve is a

bronzevalveconnectedtoaoatarmassemblyandisactivatedbyalargefoamlledplastic

oat.Theoatismountedonanallthreadrodheldinplacebywingnuts.Thewaterlevelinthe

basinisadjustedbyrepositioningtheoatandallthreadusingthewingnuts.RefertoFigure12

for details.

Figure 12 – Mechanical Water Make Up Valve

The make up valve assembly should be inspected monthly and adjusted as required. The valve

should be inspected annually for leakage and if necessary, the valve seat should be replaced.

The make up water pressure should be maintained between 140 and 340 kPa.

Drift Eliminators

Check the drift eliminators quarterly to make sure the drift eliminators are still in the correct

position and not clogged by any debris.

If required after inspection, drift eliminators must be removed, cleaned and reinstalled correctly.

On forced draft models, the worker must use personal precautions and adequate safety

measures against the risk of a fall, in accordance with local regulations. Remove one or two

eliminatorsectionsfromthetopoftheunit,protectthellbyuseofahardboardbeforeentering

theunitandwalkingonthell.Neverwalkontheeliminators!Oncestandingonthell,the

remaining drift eliminators can be removed.

On induced draft models, lifting handles are provided along the top layer of eliminators. Remove

oneortwoeliminatorsections,protectthellbyuseofahardboardbeforeenteringtheunitand

walkingonthell.Neverwalkontheeliminators!Oncestandingonthell,theremainingdrift

eliminators can be easily removed through the access door.

Pressurized Water Distribution Systems

AllEVAPCOcoolingtowersaresuppliedwithwideoricewaterdiffusers.Thewaterdistribution

system should be checked monthly to make sure it is operating properly. Always check the spray

system with the pump on and the fans off (locked and tagged out).

On forced draft units (LSTE, LPT and PMTQ models), remove one or two eliminator sections from

the top of the unit and observe the operation of the water distribution system.

On induced draft units (AT and UAT models), lifting handles are provided on several sections of

eliminators within reach of the access door. Eliminators can be easily removed from outside of

the unit to observe the water distribution system. The diffusers are essentially non-clogging and

should seldom need cleaning or maintenance.

FLOAT BALL

MAKE-UP VALVE

FLOAT ARM

ADJUSTMENT

WINGNUTS

Loading...

Loading...