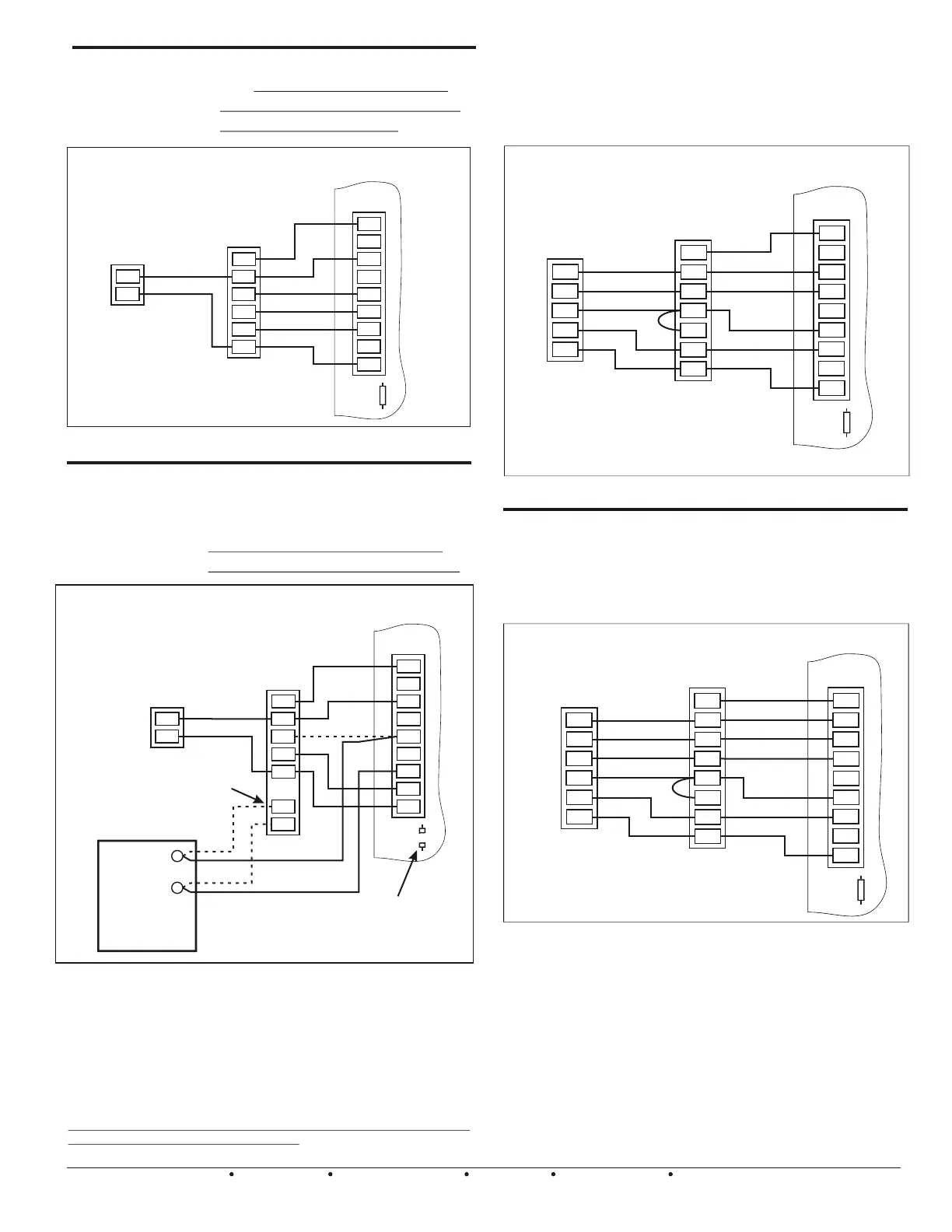

SYSTEM WIRING

Typical gas or Electric Furnace with

A/C. Note the common “C” wire is

connected to the SYSTEM terminal

block of the BMPlus 3000.

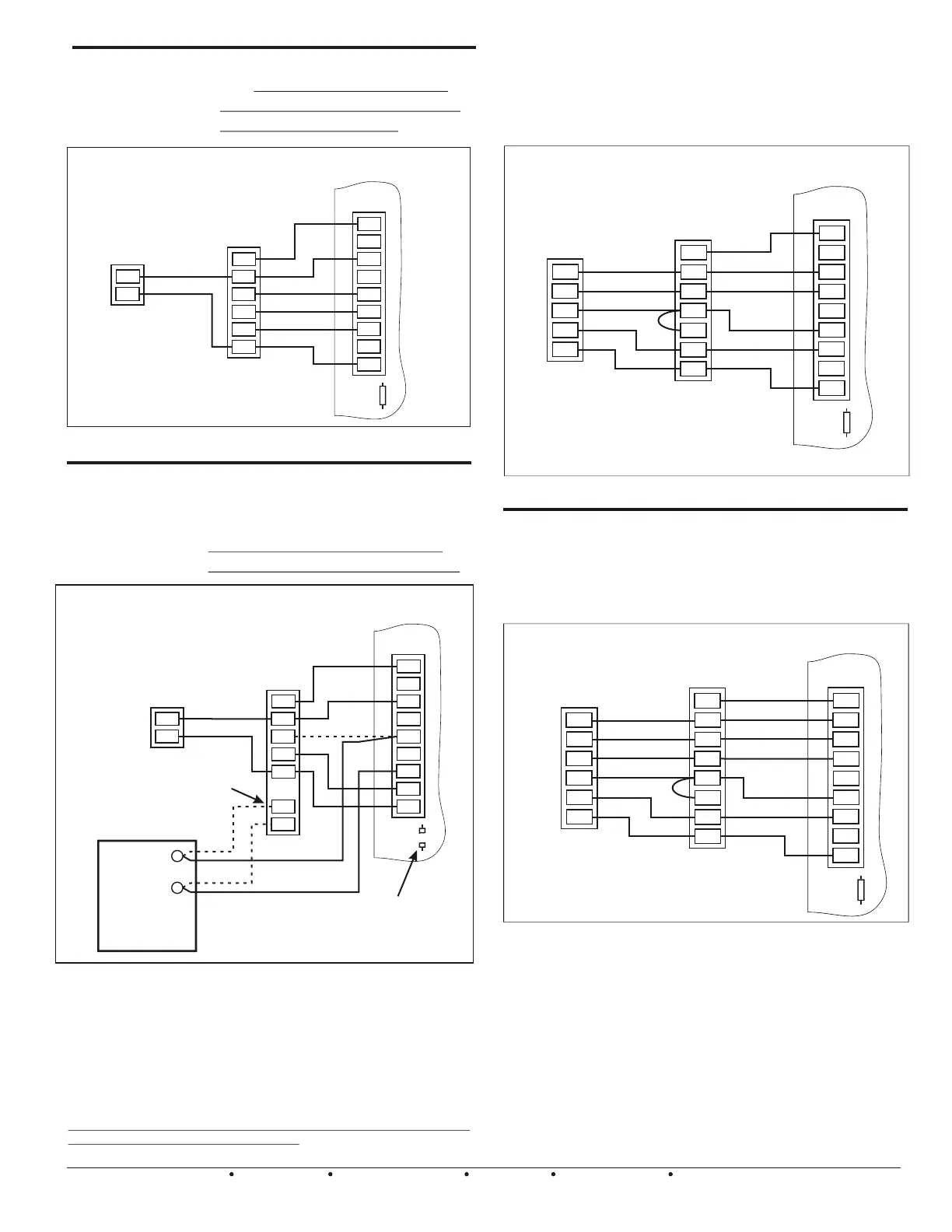

Typical heat pump system wiring with electric resistance or

Gas backup heat (No Dual Fuel kit required). This diagram

applies to air cooled or geothermal / ground source

systems.

Wiring diagram for a typical oil burner,

hydronic zone / Air handler with A/C.

Cut the Rc / Rh link on the BMPlus

Panel for systems requiring isolation.

Single

Transformer

Gas or Electric

Furnace & A/C

1 or 2 Stage Heat

Conventional or Dual Fuel 2 Heat / 1 Cool Heatpump

with O (Cool) Type Reversing Valve

Two

Transformer

Systems

Figure 7 Single transformer Conventional system.

Figure 9 -- 2 Heat / 1 Cool Heat Pump System

Figure 8 Two transformer Oil or Hydronic / A/C system.

Conventional or

Dual Fuel 3 Heat /

2 Cool Heat Pump

with O (Cool) Type

Reversing Valve

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

Y

R

C

T

T

Y

W

G

C

Figure 10 – 3 Heat / 2 Cool Heatpump System

HEAT PUMP

2 STAGE

BMPlus 3000

**Note that a Conventional & Dual fuel heat pump wire up more or less the

same. The difference is how auxiliary heat operates. In a Conventional

system, the indoor fan & the compressor continues to run when auxiliary

energizes. In a Dual Fuel system, the indoor fan & the compressor shuts

down when auxiliary energizes. The BMPlus 3000 will perform these

functions automatically. All you have to do is set the dip switches to the

correct settings. Select CONV or DF at dip switch #2. Install regular

Heat/Cool thermostats and choose to activate auxiliary heat by TIMER or by

OUTSIDE AIR TEMPERATURE. (Optional Sensor required). Or you may

choose to install Heat Pump Thermostats on all zones. When the thermostat

auxiliary heat demand is satisfied, the BMPlus 3000 will stage down, unless

DF or OAS has been selected and the outdoor temperature is lower than the

OAS changeover setting. In that case the system will continue in FUEL

mode, until all current heating demands are satisfied.

* Note: Your Air Handler may include a W terminal. That means

it may have it’s own isolation circuit. If you can confirm this,

simply connect the W1/B terminal to the W terminal on the air

handler. Do not cut the Rc/ Rh jumper. Wire up your Oil Burner,

Circulator relay, or Hydronic Zone valve to the isolation

contacts or wires provided in the air handler. The fan is

controlled via the time delay relay inside the air handler.

Don’t worry if you accidentally cut the Rc/Rh link. Just install your

own jumper across the Rc/Rh terminals!

AIR HANDLER

OR 1 0R 2 STAGE

GAS FURNACE

HEAT PUMP

1 STAGE

BMPlus 3000

Conventional or Dual Fuel Heat Pump wiring

with 3 Heat / 2 Cool. With electric or Gas

Furnace Backup (No dual fuel kit is required).

This diagram applies to air cooled or

geothermal / ground source systems.

EWC Controls Inc. 385 Highway 33 Englishtown, NJ 07726 800-446-3110 FAX 732-446-5362 E-Mail- info@ewccontrols.com

6

You may need

to Cut the

RC/RH Link

Boiler Control

OR

Zone Valve Control

OR

Circulator Control

OIL

BURNER

PRIMARY

CONTROL

OR

TYPICAL FAN

CENTER

TERMINAL

BLOCK

OUTDOOR

CONDENSING

UNIT

T

T

ISOLATION

TERMINALS

OR WIRES

BMPlus 3000

Y

C

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

Y

W1

W2

R

C

G

BMPlus 3000

GAS or Electric

Furnace

1or2 STAGE

OUTDOOR

CONDENSING

UNIT

To make troubleshooting

easier, connect the “C”

Common from the Furnace

to the BMPlus. If you don’t

connect it, it’s OK.

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

O

X/W

R

C

Y

O

W1

W2

R

C

G

Y

SYSTEM

O

W1/B

G

Y2

Y1

RH

RC

C

W2/E

RC/RH

LINK

O

X/W

R

C

O

W1

W2

R

C

G

Y1

*

Y2

Y1

Y2

AIR HANDLER

OR 1 0R 2 STAGE

GAS FURNACE

Loading...

Loading...