DVC5000 Series

November 1999

3-4

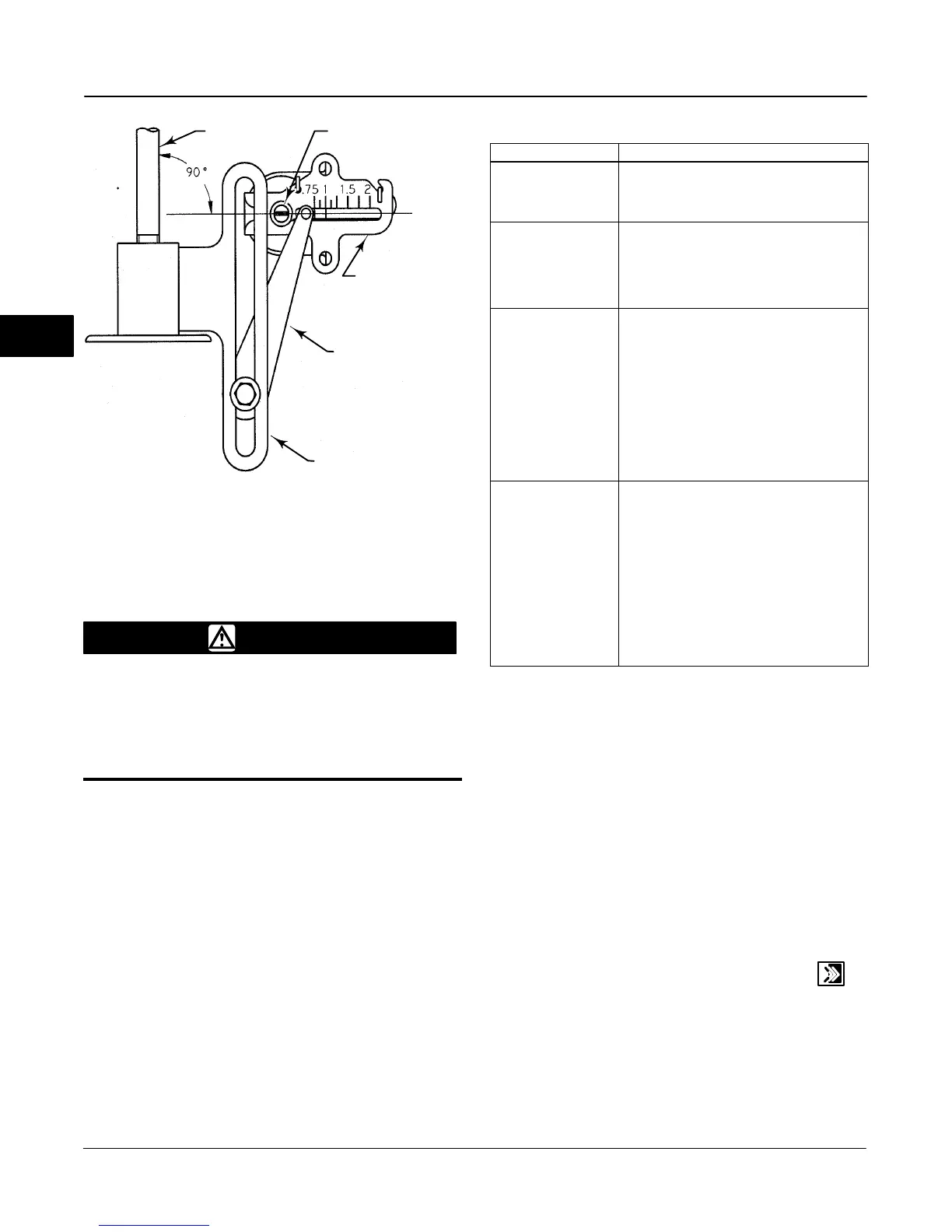

A6536 / IL

Figure 3-4. Crossover Point

ACTUATOR

STEM

TRAVEL SENSOR SHAFT

FEEDBACK ARM

CONNECTOR ARM

ADJUSTMENT ARM

Auto Calibrate Travel

WARNING

During calibration the valve will move

full stroke. To avoid personal injury

and property damage caused by the

release of pressure or process fluid,

provide some temporary means of

control for the process.

Select Auto Calib Travel then follow the prompts on

the HART Communicator display to automatically

calibrate travel.

1. If the Feedback Connection is Sliding-Stem

Standard, the HART Communicator prompts you to

select the method of crossover adjustment: manual,

last value, or default. Manual adjustment is

recommended for initial travel calibration.

2. When prompted by the HART Communicator,

make the crossover adjustment by adjusting the

current source until the feedback arm is 90° to the

actuator stem, as shown in figure 3-4.

3. The remainder of the auto-calibration procedure is

automatic. After completing auto travel calibration, the

HART Communicator prompts you to place the

instrument In Service and verify that the travel

properly tracks the current source.

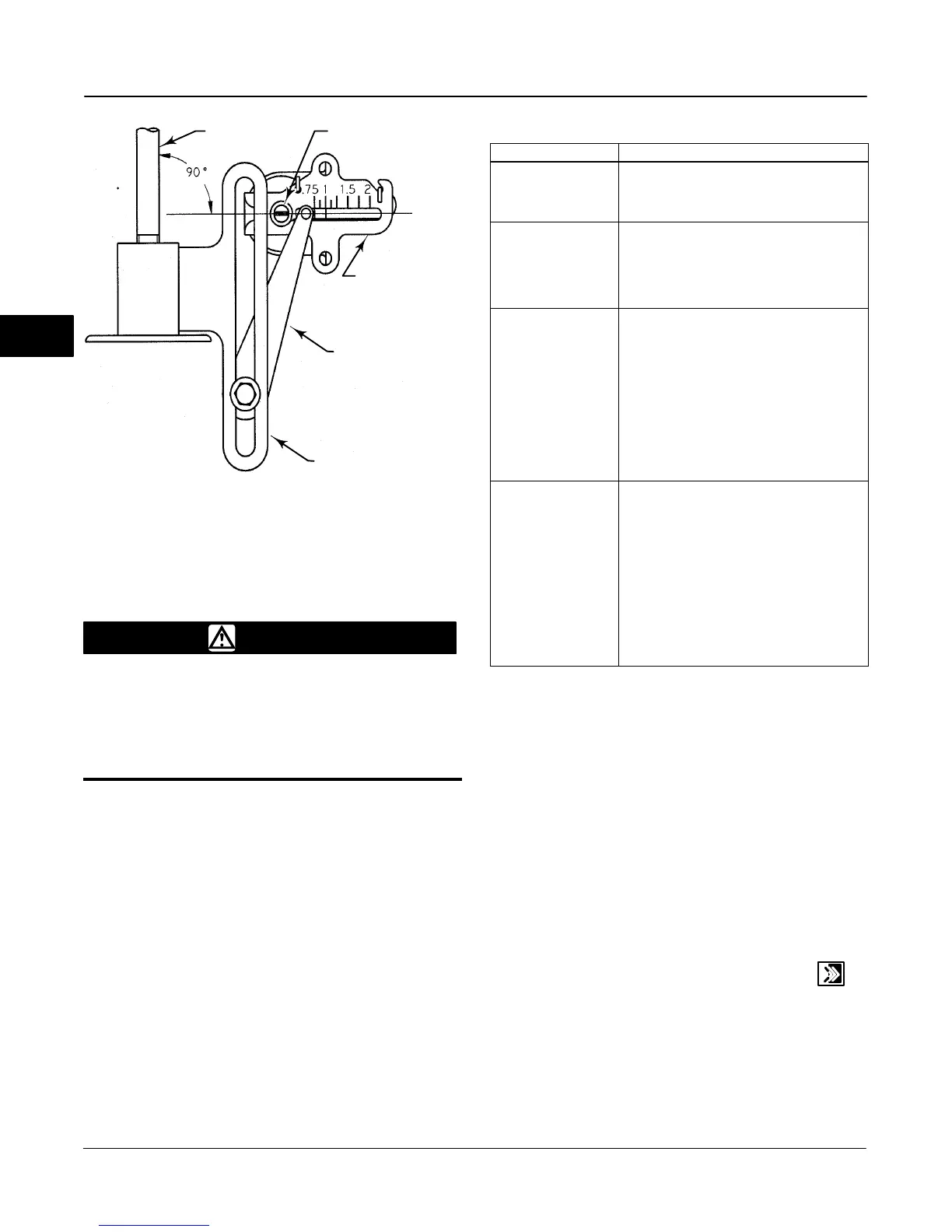

Table 3-3. Auto Calibrate Travel Error Messages

Error Message Possible Problem and Remedy

Input current must

exceed 3.8 mA for

calibration.

The analog input signal to the instrument

must be greater than 3.8 mA. Adjust the

current output from the control system or the

current source to provide at least 4.0 mA.

Place Out Of Service

and ensure Calibrate

Protection is disabled

before calib.

The Instrument Mode must be Out of Service

and the Protection must be None before the

instrument can be calibrated. For information

on changing instrument mode and protection,

see Instrument Mode and Configuration

Protection in this section.

Calibration Aborted.

An end point was not

reached.

The problem may be one or the other of the

following:

1. The tuning set selected is too low and the

valve does not reach an end point in the

allotted time. Press the Hot Key, select

Stabilize/Optimize then Increase Response

(selects next higher tuning set).

2. The tuning set selected is to high, valve

operation is unstable and does not stay at an

end point for the allotted time. Press the Hot

Key, select Stabilize/Optimize then Decrease

Response (selects next lower tuning set).

Invalid travel value.

Check travel sensor

and feedback arm

adjustments, and inst

supply press. Then,

repeat Auto Calib.

Verify proper mounting by referring to the

appropriate mounting instructions.

Verify instrument supply pressure by referring

to the specifications in the appropriate

actuator instruction manual.

Verify travel sensor adjustment by performing

the appropriate Travel Sensor Adjust

procedure in the FIELDVUE DVC5000 Series

Digital Valve Controller Instruction Manual –

Form 5335.

Making the crossover adjustment with the

valve positioned at either end of its travel will

also cause this message to appear.

If the unit does not calibrate, refer to table 3-3 for error

messages and possible remedies.

If after completing auto setup and auto calibration the

valve cycles or overshoots, or is unresponsive, you

can improve operation by selecting Stabilize/Optimize

from the Auto Setup menu. For additional information,

refer to Stabilizing or Optimizing Valve Response in

this section.

Stabilizing or Optimizing Valve

Response

If after completing initial setup and auto calibration the

valve seems slightly unstable or unresponsive, you

can improve operation by pressing the Hot Key

and selecting Stabilize/Optimize, or select

Stabilize/Optimize from the Auto Setup menu.

To stabilize valve operation, select Decrease

Response. This selects the next lower tuning set (e.g.,

F to E). To make the valve more responsive, select

Increase Response. This selects the next higher

tuning set (e.g., F to G).

3

Loading...

Loading...