DVC5000 Series

November 1999

4-6

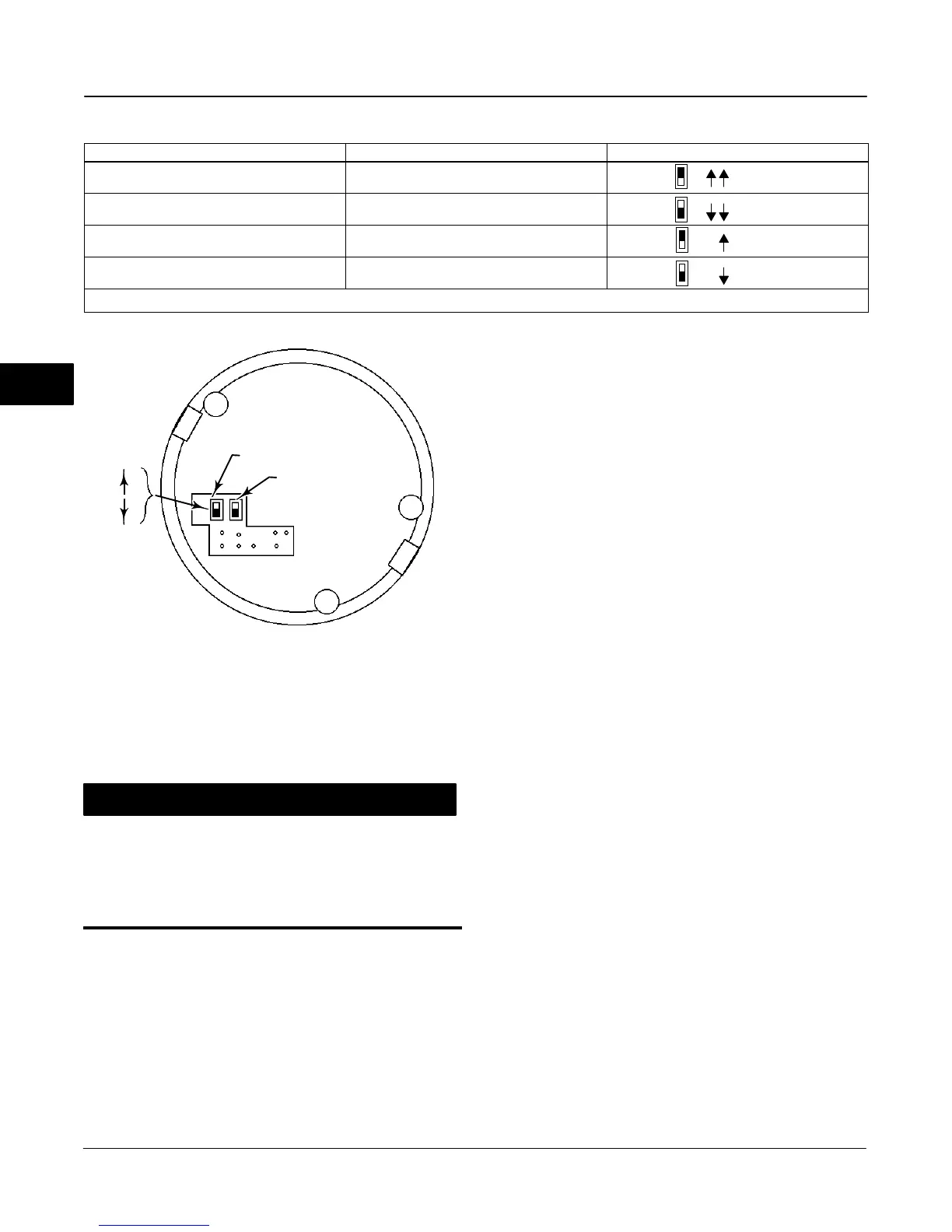

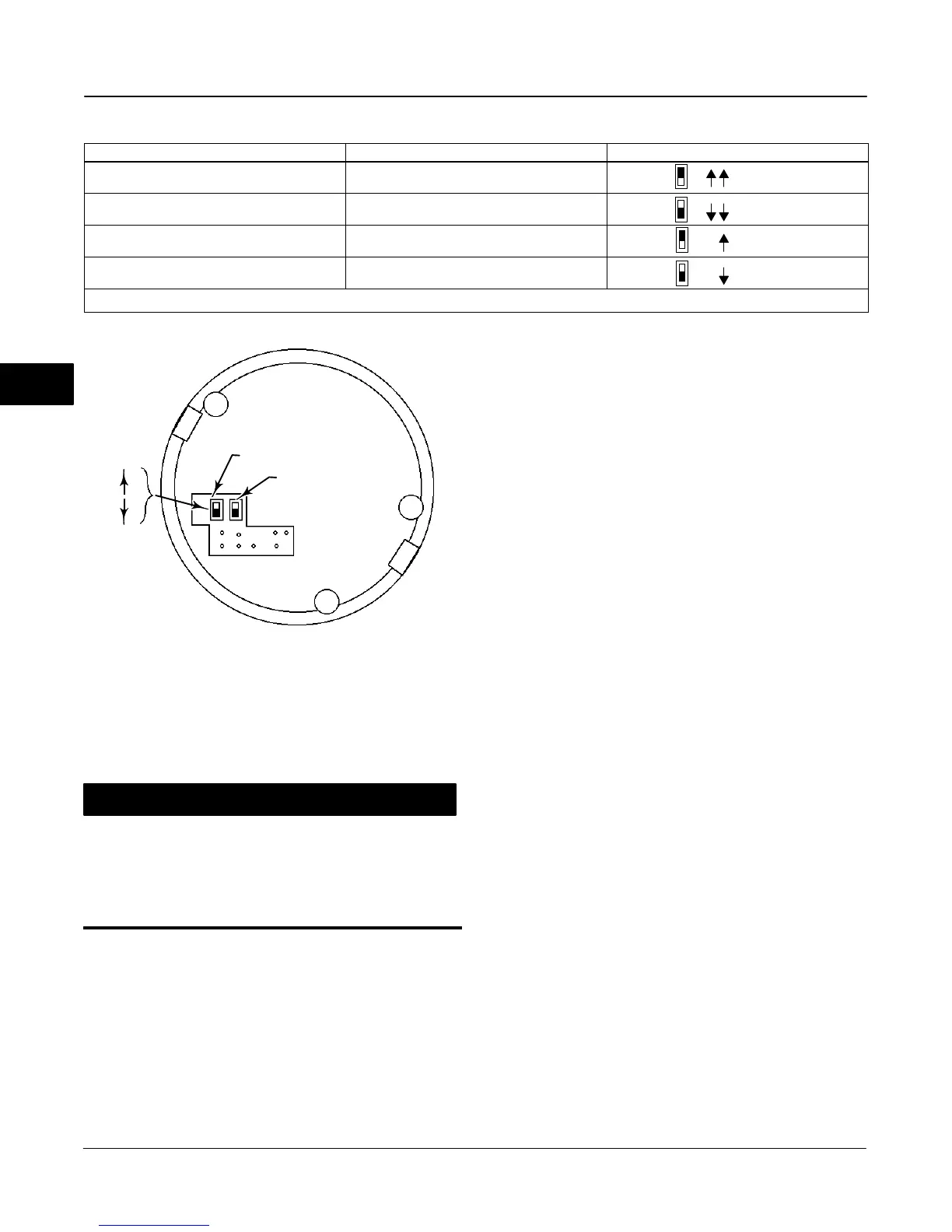

Table 4-1. DIP Switch Configuration

(1)

DIP SWITCH FUNCTION SWITCH SWITCH POSITION

Multidrop Loop Multi-drop

UP

Point-to-Point Loop Multi-drop

DOWN

Auxiliary Terminal, Transmitter Auxiliary

UP (2)

Auxiliary Terminal, Switch Auxiliary

DOWN

1. Refer to figure 4-6 for switch location..

2. Auxiliary terminal, transmitter is available only with the Process PID option.

Figure 4-6. DVC5000 Series Digital Valve Controller

DIP Switch Location

BACK OF PWB ASSEMBLY

SUB-MODULE

MULTI-DROP SWITCH

AUXILIARY SWITCH

UP

DOWN

A6191-2/IL

X

X

NOTE:

X INDICATES PIN REMOVED FOR CONNECTOR KEYING.

CAUTION

Do not use excessive force with the

screwdriver when prying out the relay.

The lip of the notch may break, which

would not allow the O-ring to seal

properly.

Replacing the Pneumatic Relay

1. Ensure the compartment in the module base that

holds the relay is clean.

2. Visually inspect the 0.016-inch hole in the module

base (the fixed bleed on the relay output) to ensure it

is clean and free of obstructions. If cleaning is

necessary, do not enlarge the hole.

3. Apply sealant to four O-rings on the relay.

4. Insert the relay submodule into the module base.

You will feel a slight resistance as the O-rings engage.

No orientation of the relay is necessary.

5. Push on the relay until the O-rings are seated in

their respective bores and the input diaphragm makes

contact with the bottom of the bore. Take care not to

damage the supply port during assembly.

6. If not already installed, attach the coil spring and

O-ring onto the valve plug, and insert the valve plug

through the supply port of the relay.

7. Insert the four screws through the cap. Install the

O-rings on the screws until the O-rings are inside the

counterbored holes and not protruding past the

surface of the cap.

8. Place the Belleville spring in the relay cap, with its

inside diameter contacting the relay cap. Place the

spring washer, with its three fingers pointing up,

against the Belleville spring.

9. Install the relay cap on the module base. As the

relay cap is installed, the spring washer fingers will

grab the relay cap and retain the Belleville spring.

Tighten the screws, in an crisscross pattern, to a final

torque of 20.7 lbfSin (2 NSm).

4

Loading...

Loading...