9-3. Pump down

WARNING

• Never touch electrical components such as the terminal blocks except the button on the display

board. It may cause a serious accident such as electric shock.

•

During the pump-down operation, make sure that the compressor is turned off before you re-

move the refrigerant piping.

Do not remove the connection pipe while the compressor is in operation with 2-way or g. 3-way

valve open. This may cause abnormal pressure in the refrigeration cycle that leads to breakage

and even injury.

CAUTION

• Perform the pump down operation before disconnecting any refrigerant pipe or electric cable.

•

Collect refrigerant from the service port or the 3-way valve if pump down cannot be performed.

• In case of a group control system installation, do not turn the power off until pump down is com-

pleted in all outdoor units.

(Group control system installation described in “SPECIAL INSTALLATION METHODS” in the in-

stallation manual of the indoor unit.)

¢

Pu

mp down procedure

Confirm that the power is off, and then open the service panel.

Symbols in the following table indicate LED status.

"○": Lights off, "●": Lights on

1. Check the 3-way valves (both the liquid side and gas side) are opened.

2.

Turn the power on.

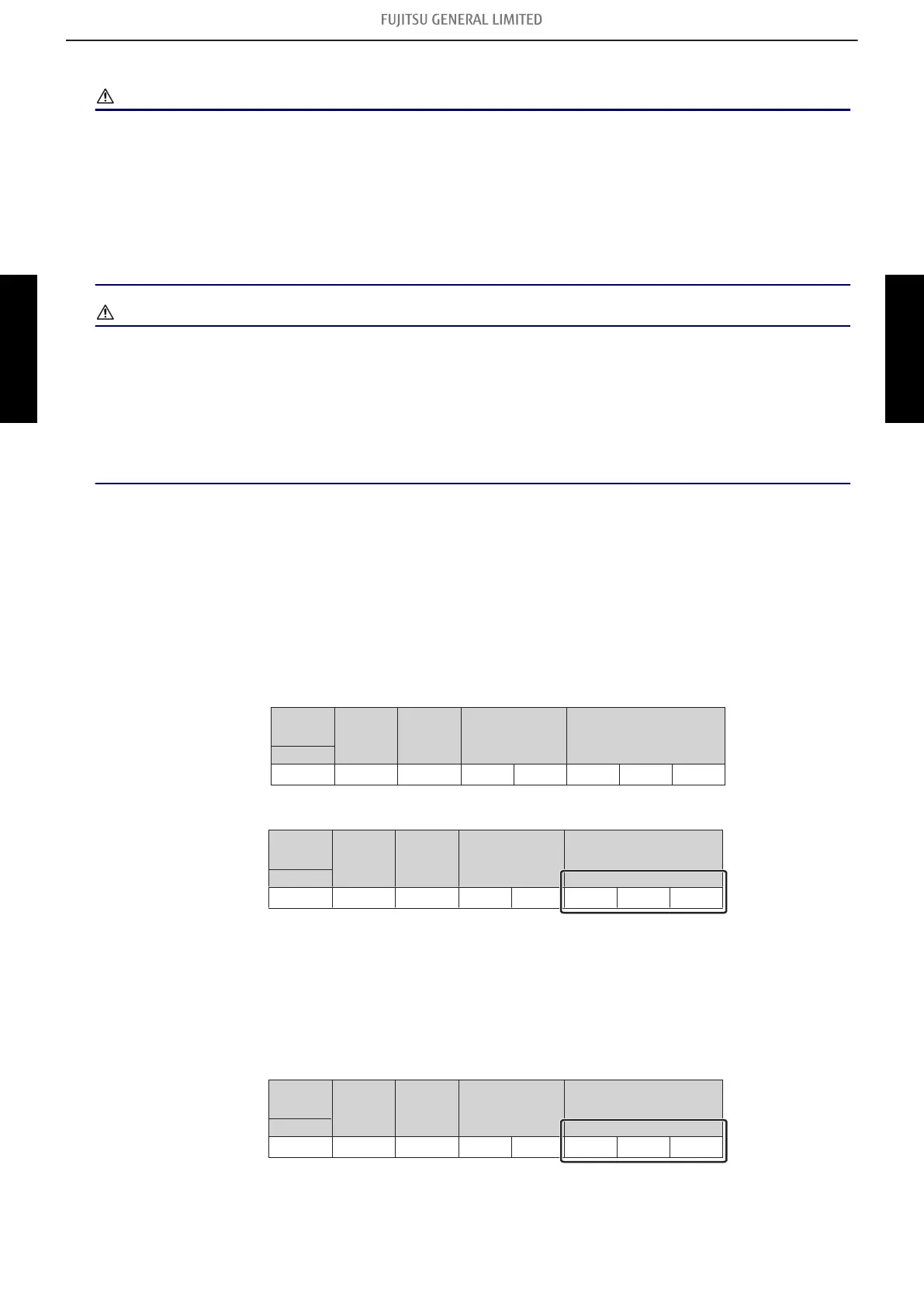

POWER

ERRO

R

PUMP

DOWN

LOW

NOISE

PEAK

CUT

MODE (L1) (L2) (L3) (L4) (L5) (L6)

● ○ ○ ○ ○ ○ ○ ○

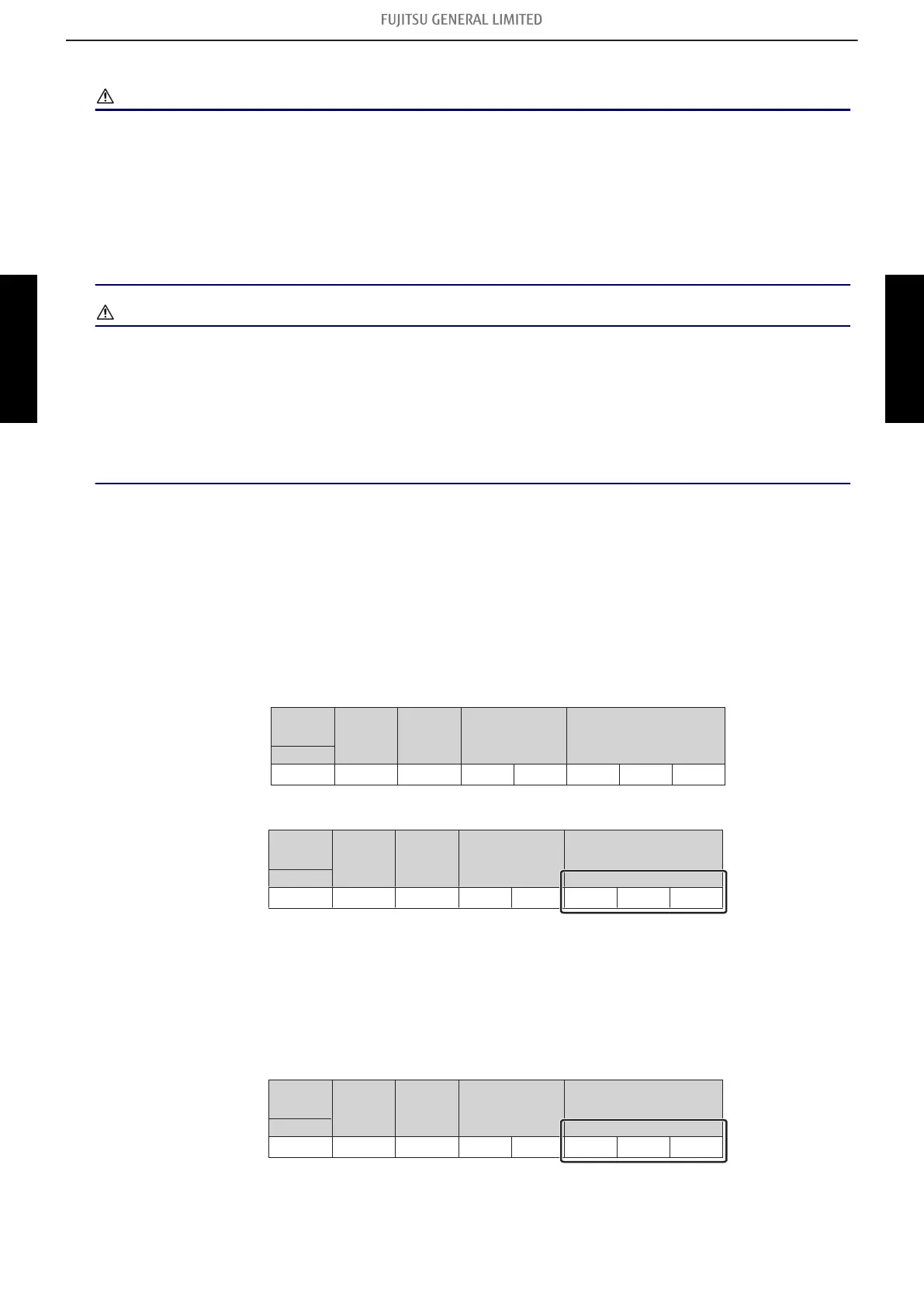

3. Press [PUMP DOWN] button for 3 seconds or more after 3 minutes after power on.

POWER

ERROR

PUM

P

DOWN

LOW

NOISE

PEAK

CUT

MODE (L1) (L2) (L3) (L4) (L5) (L6)

● ○ ● ○ ○ ● ● ●

LED display lights on as shown in the above figure, and the fans and the compressor start op-

erating.

NOTE: If the [PUMP DOWN] button is pressed during compressor operation, the compres-

sor will stop, and the operation will start after about 3 min.

4. LED display will change as shown below about 3 minutes after the compressor starts. Fully

close the 3-way valve on the liquid pipe side at this stage.

POWER

ERROR

PUMP

DOWN

LOW

NOISE

PEAK

CUT

MODE (L1) (L2) (L3) (L4) (L5) (L6)

● ○ ● ○ ○ ○ ● ●

NOTE: If the valve on the liquid pipe side is not closed, the pump down cannot be per-

formed.

- 196 -

9-3. Pump down 9. Check and test

SYSTEM

DESIGN

SYSTEM

DESIGN

Loading...

Loading...