GEI-86134,

Power Circuit

Breqkers

I

BREAKER

\

\

CLOSED POSITION

/

ACTUATOR

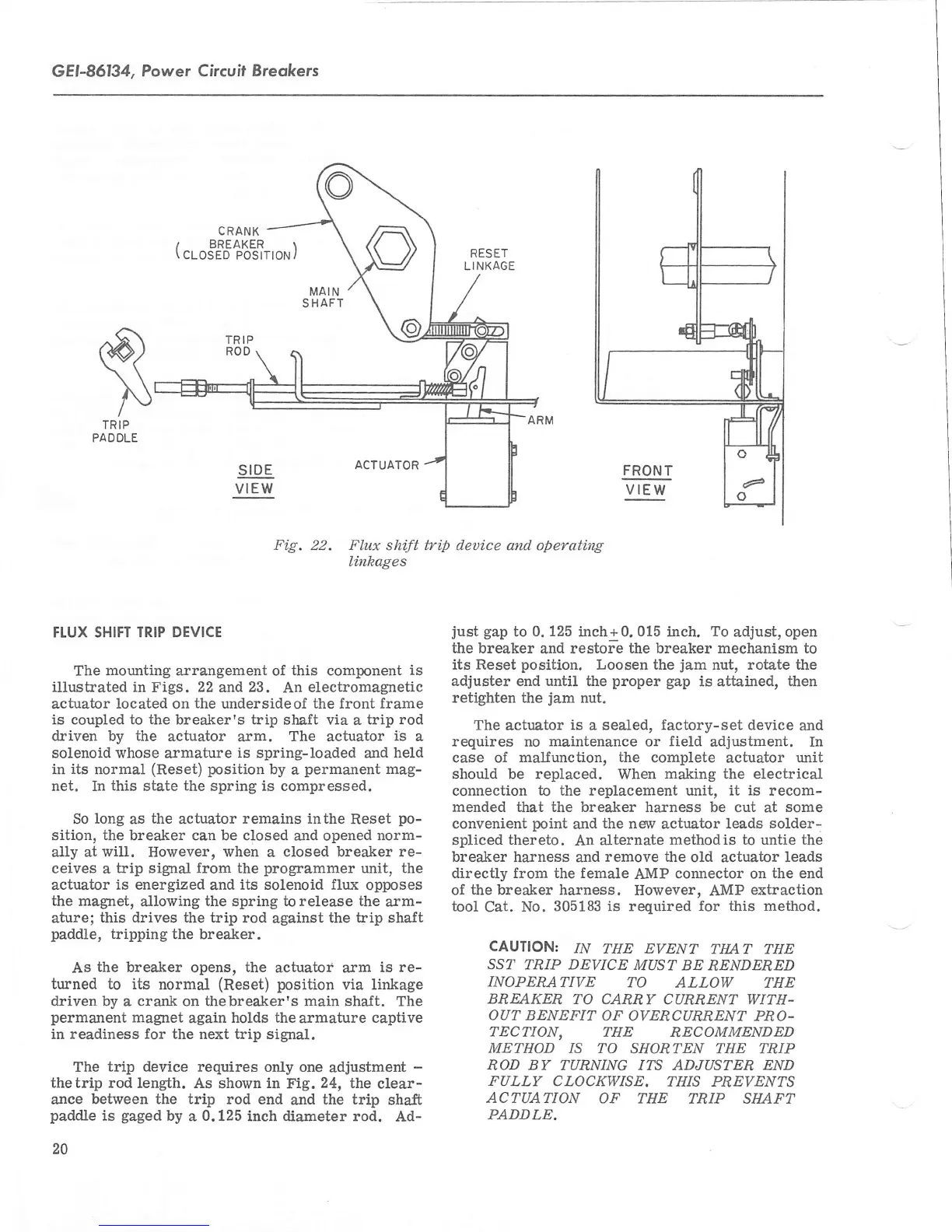

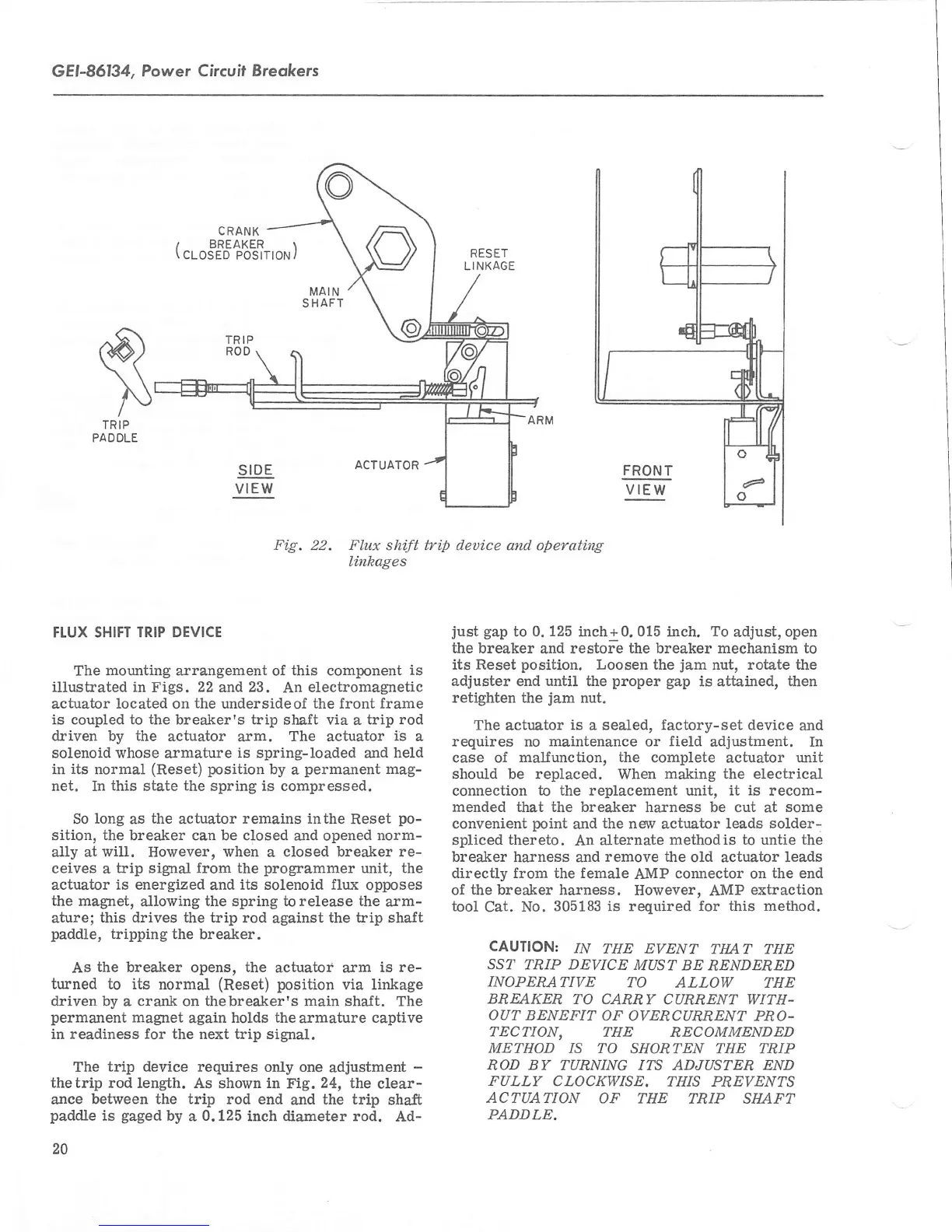

Fig.

22. Flux shi.ft trip deuice and operating

li.nkages

FLUX SHIFT TRIP DEVICE

The

mounting arrangement

of

this component

is

illustrated in Figs. 22 and23.

An

electromagnetic

actuator

located

on

the

undersideof the front frame

is coupled to

the

breaker's trip

shaft

via

a

trip rod

driven

by

the

actuator

arm.

The

acfuator

is

a

solenoid whose

armature

is spring-loaded

and

held

in

its

normal

(Reset)

position

by

a

permanent

mag-

net. In

this

state

the

spring is compressed.

So

long

as

the

acfuator

remains inthe

Reset

po-

sition, the breaker can be closed

and opened

norm-

ally

at will.

However,

when

a

closed breaker re-

ceives

a

bip signal from the

programmer

unit, the

actuator

is energized

and

its solenoid flux

opposes

the magnet,

allowing

the spring to release the

arm-

ature;

this drives the trip

rod

against

the trip

shaft

paddle,

tripping the

breaker.

As

the

breaker

opens,

the

actuator arm

is

re-

turned to its

normal

(Reset) position

via linkage

driven by

a

crank on thebreaker's main sha-ft.

The

permanent

magnet

again

holds

the

armature

captive

in

readiness for

the next trip signal.

The

trip device requires

only one

adjustment

-

thetrip rod length. As

shown

in

Fig.

24,

the

clear-

ance

between the trip rod

end

and

the trip

shaft

paddle

is

gaged

by

a

0.125

inch diameter rod.

Ad-

20

just

gap

to

0. 125

inch+ 0. 015 inch.

To

adjust,

open

the breaker

and restore

the breaker mechanism to

its Reset

position.

Loosen the

jam

nut, rotate the

adjuster

end

until

the

proper gap

is attained, then

retighten the

jam

nut.

The

actuator

is

a sealed,

factory-set

device

and

requires

no

maintenance

or

field

adjustment. In

case of malfunction,

the

complete actuator

unit

should be replaced.

When

making

the electrical

connection

to

the replacement unit, it

is

recom-

mended that the breaker harness

be cut

at

some

convenient

point

and

the

new actuator leads

solder-

spliced

thereto.

An

afternate

methodis to untie the

breaker harness and

remove the

old

actuator

leads

directly from the female

AMP

connector on

the end

of

the breaker harness.

However.

AMP

extraction

tool

Cat.

No.

305183 is required for

this method.

CAUTION:

IN

THE EVENT

TIIAT THE

SST TRIP DEVICE

MUST BE

RENDERED

INOPERATIVE

TO

ALLOW THE

BREAKER

TO

CARRY CURNENT WITH-

OUT

BENEFIT

OF OVERCURRENT

PRO-

TECTION, THE

RECOMMENDED

METHOD /S TO

SHORTEN THE TRIP

ROD

BY

TURNING ITS ADJUSTEN END

FULLY

CLOCKWISE.

THIS PREVENTS

ACTUATION

OF THE

TRIP SHAFT

PADDLE,

Loading...

Loading...