35

F. COMMISSIONING - HORIZONTAL

WARNING: The system must be lled

with water at all times once commissioned. Failure

to do so may cause the system to dry and become

damaged, resulting in personal injury, illness, and/or

death.

Do not turn on any hot water taps when ushing the

system during commissioning or maintenance. If

hot water is used, high levels of factory preservative,

chlorine, or MC1 cleaning agent may enter the hot

water tank and may cause personal injury, illness, and/

or death.

Disposable protective gloves must be worn during

commissioning of the system to protect your hands. At

the end of the procedure, wash your hands thoroughly

with soap and water. Do not reuse gloves. Dispose of

gloves in the garbage.

Filling and Flushing

WARNING: If the system cap is not

properly tightened and/or the O-ring is not clean,

system leaks may occur. Leaks may cause personal

injury or property damage. Take care not to cross-

thread the system cap during cap installation. Apply

DOW CORNING 111 silicone to O-ring and threads. Spin

system cap by hand until it stops. Then tighten with

supplied wrench 1/2 turn. If cap leaks, turn o water

and turn additional 1/4 turn.

When the internal prelter is removed, ensure the

thimble lter remains in place, seated in the spigot of

the prelter cavity. Removal of the thimble lter may

permit damage to the system membrane, which may

lead to illness or death.

1

Remove the system cap and remove the internal

prelter. Place the internal prelter in a clean, dry area. Ensure

that the thimble lter is seated properly. Replace the system

cap and tighten as described above.

For models with a stainless steel prelter, a carbon prelter

may be purchased separately if desired.

Make sure vent valve is loose (1/4 turn).

Open

Close

Internal

Prefilter cavity

Figure 61

2

Slowly open the inlet valve half way, allowing water into

the system. Avoid opening the inlet valve quickly as this will

introduce air pockets that will take longer to escape. Keep the

outlet valve closed. Check for any leaks in the plumbing. If

present, close the inlet valve immediately and repair. As

pressure builds in the system air will begin to escape from the

air relief valve. Once air is no longer passing through the air

relief valve, the system is pressurized.

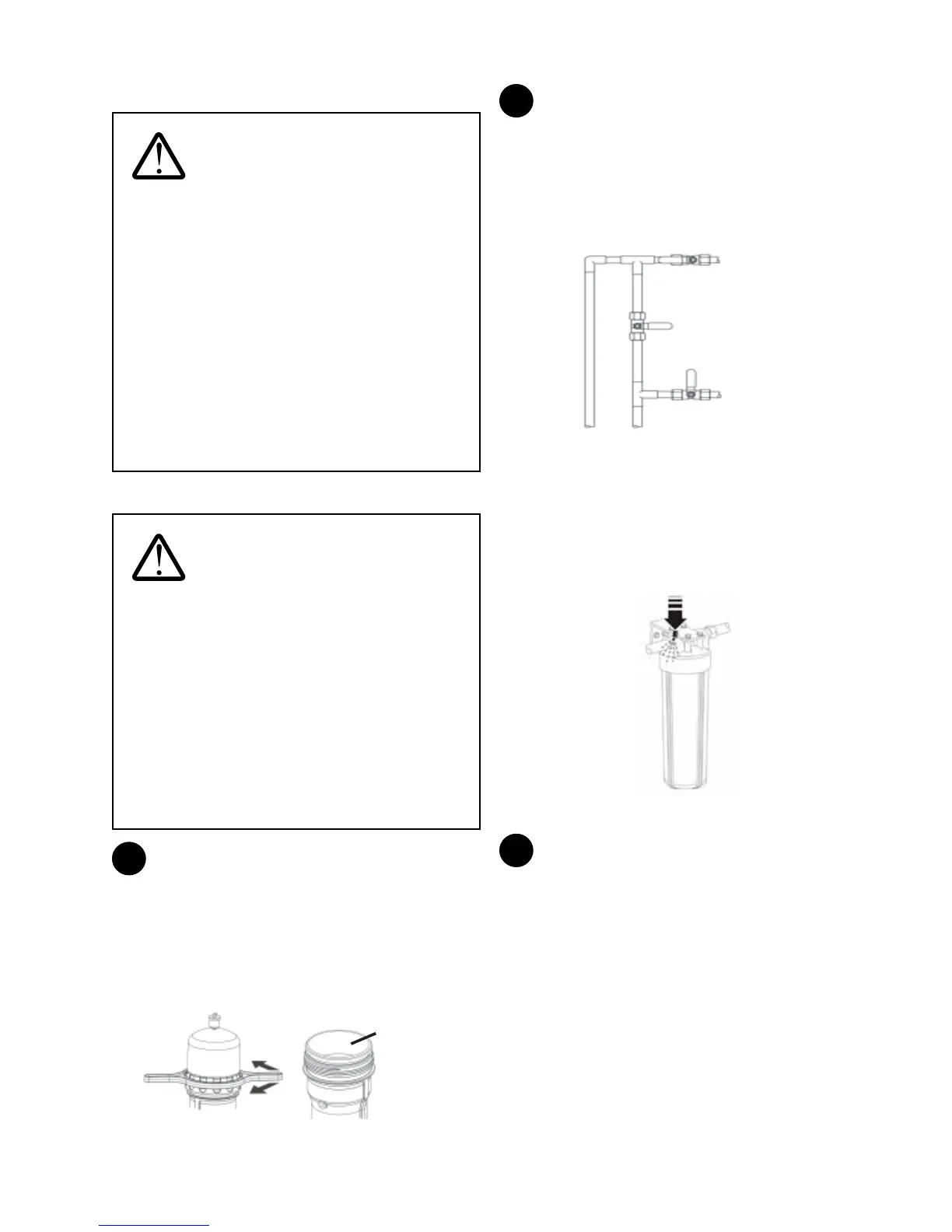

Inlet valve

Outlet valve

Figure 62

For horizontally-mounted systems, check to make sure that no

air comes out from the air relief valve.

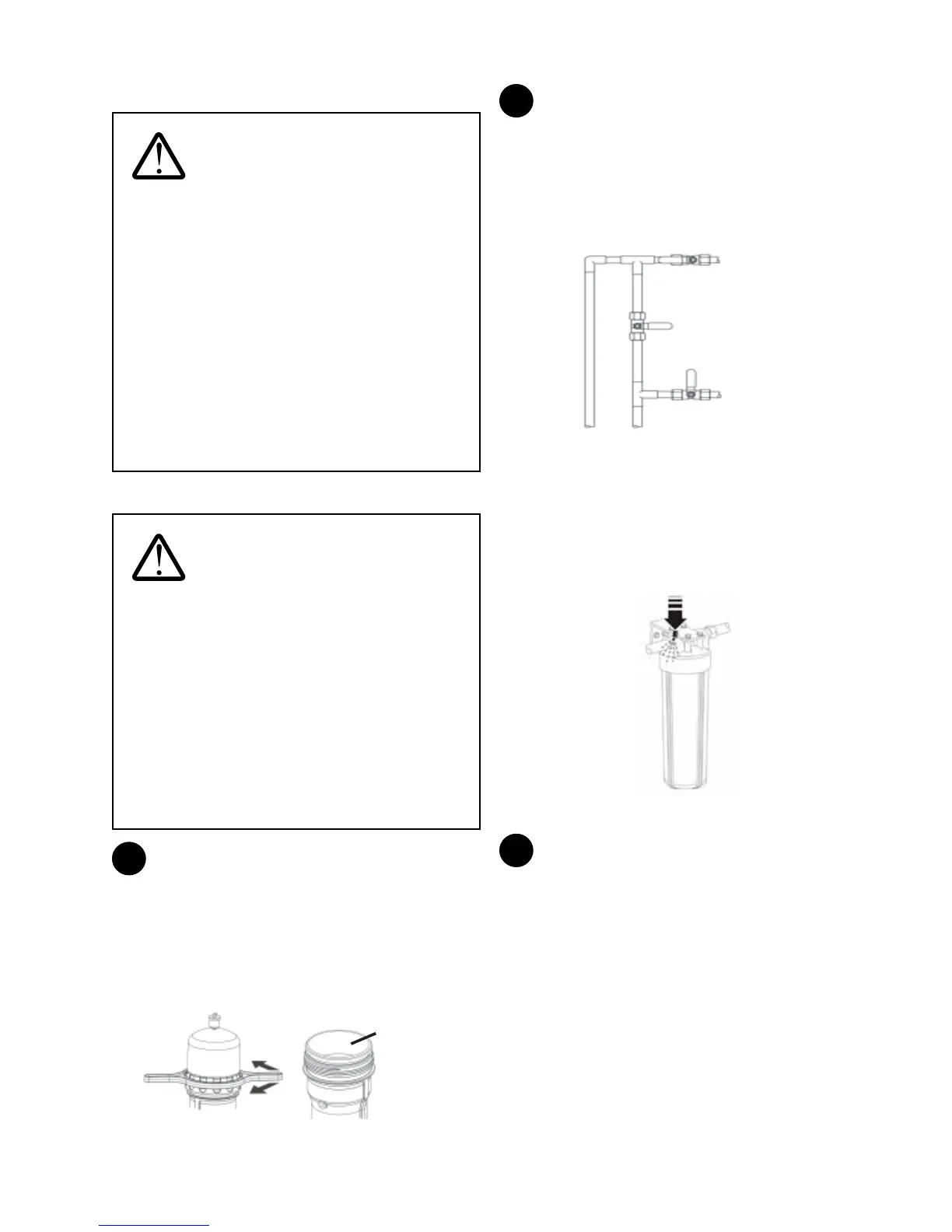

If an external prelter is installed, depress the red button on

the external prelter head to allow air to escape from the

external prelter housing. Once water emerges from the

button, all air has been removed.

Figure 63

3

Using the controller, initiate a manual ush sequence.

Refer to the instructions in the Controller Functions section on

how to perform a manual ush sequence. Following the

manual ush, open a cold water tap that is downstream of the

system. Allow water to ow for 15 minutes. The system

requires a 15-minute ush to remove the food-grade factory

preservative.

Loading...

Loading...