Do you have a question about the GE LOGIQ F8 and is the answer not in the manual?

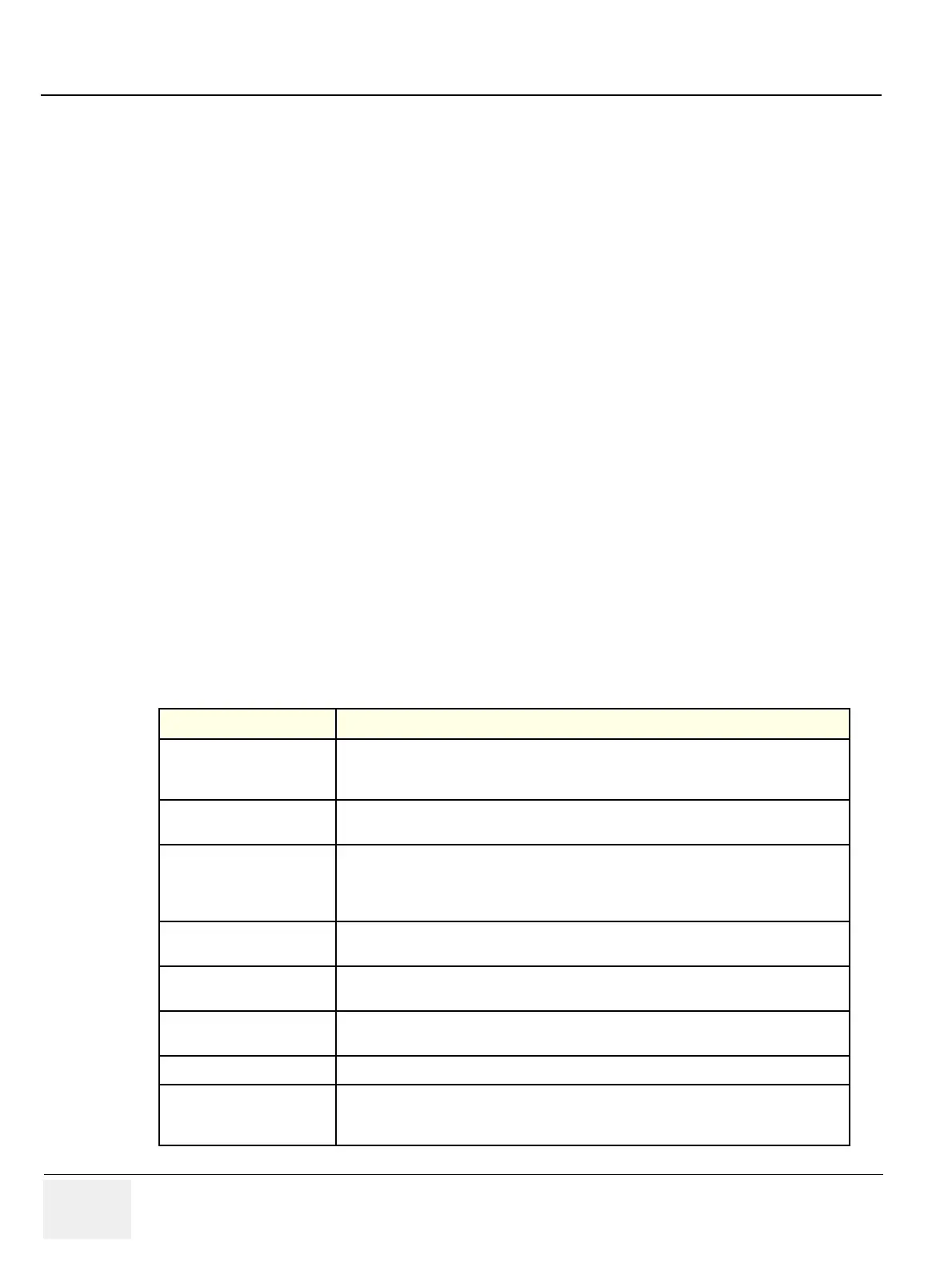

| Type | Ultrasound System |

|---|---|

| Probe Ports | 3 active probe ports |

| Probe Connectors | 3 |

| Portability | Portable |

| Operating Temperature | 10°C to 40°C |

| Relative Humidity | 30% to 85% (non-condensing) |

| Power Requirements | 100-240 V AC, 50/60 Hz |

| Imaging Modes | Color Doppler, Power Doppler |

| Applications | Abdominal, Vascular, Cardiac, Musculoskeletal, Small Parts |

| Frequency Range | 2.0 MHz - 18.0 MHz (dependent on transducer) |

| Storage Temperature | -20°C to 60°C |

Provides an overview of Chapter 1 and the manual's purpose.

Explains book conventions, hazard icons, and safety messages.

Details human, mechanical, and electrical safety precautions.

Discusses electromagnetic compatibility, interference, and static discharge prevention.

Outlines procedures for applying Lockout/Tagout for service.

Provides contact information for support and troubleshooting.

Introduces site preparation requirements for installation.

Covers environmental and electrical requirements for the console.

Details purchaser responsibilities and required facility features.

Outlines information needed for unit installation and setup procedures.

Provides reminders and average installation times.

Details procedures for receiving and unpacking the system.

Covers verification, inspection, and EMI protection before installation.

Guides through powering on/off and connecting probes.

Details system specifications, optional peripherals, and connector panels.

Refers to the User Manual for software and option configuration.

Provides a worksheet for network connectivity setup.

Refers to procedures for loading base image software.

Explains how to check system software version.

Covers documentation and user manual checks.

Introduces procedures for checking system functions and diagnostics.

Lists equipment needed for functional tests.

Details general procedures like power on/off, date/time check, and mode controls.

Explains system concepts, component arrangement, and subsystem functions.

Presents system and software block diagrams.

Describes the common software modules for service.

Introduces scanner testing and adjustment procedures.

Provides procedures for adjusting monitor brightness and light.

Details tools and software for maintaining image quality and system operation.

Explains how to capture trouble images and system data for analysis.

Guides on capturing screen images and setting up print keys.

Covers utilities like disruptive mode and system shutdown.

Details procedures for connecting the system to a network.

Introduces procedures for replacing modules and subsystems.

Provides warnings and cautions for disassembly.

Provides an overview of renewal parts for the LOGIQ F Series.

Lists abbreviations used in the renewal parts section.

Discusses periodic maintenance and the purpose of care.

Explains the importance of keeping records and quality assurance.

Outlines the recommended customer care and maintenance schedule.

Lists standard GE tool kits and special tools for maintenance.

Provides troubleshooting steps for leakage current failures.