Do you have a question about the GE OSMONICS E4 Series and is the answer not in the manual?

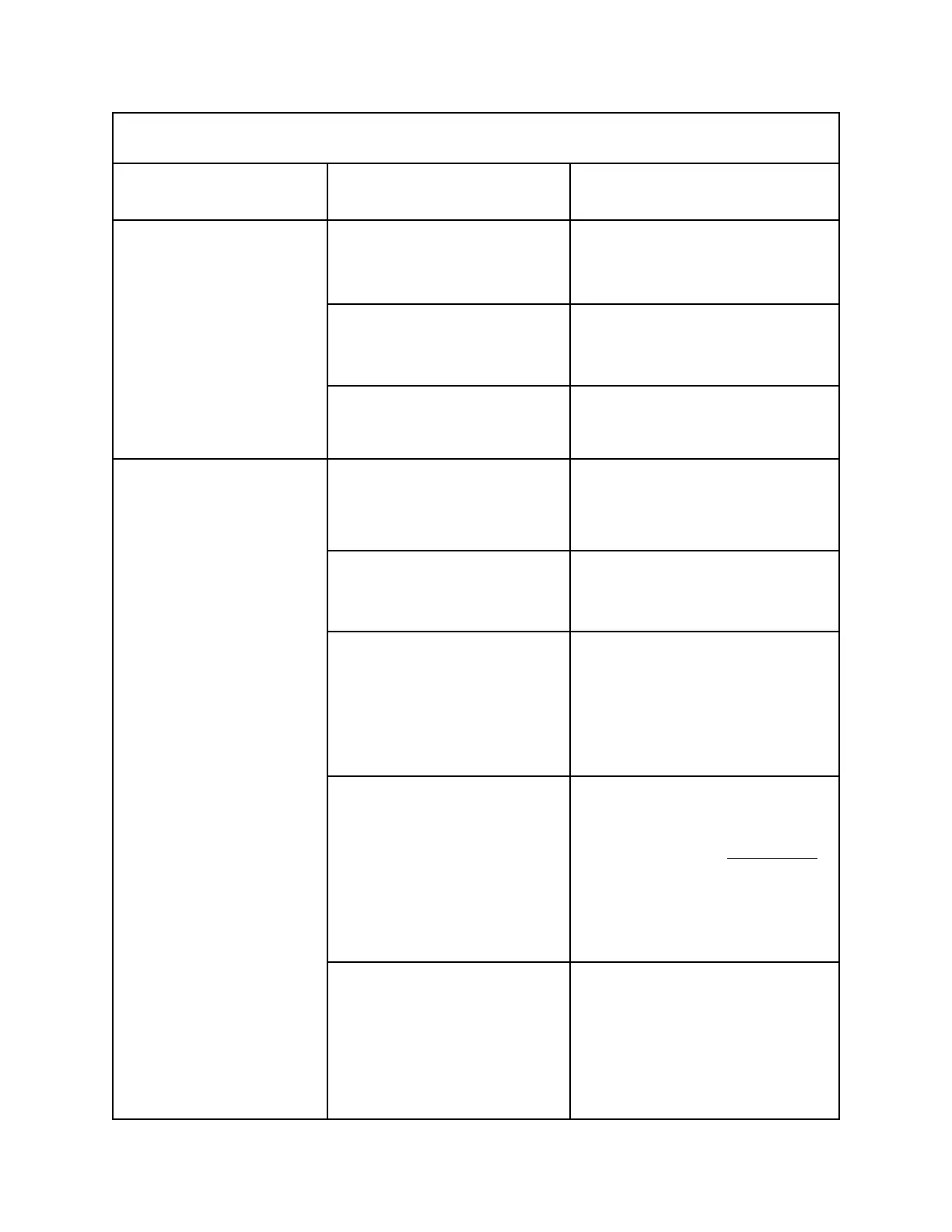

| Category | Water Filtration Systems |

|---|---|

| Model | E4 Series |

| Manufacturer | GE OSMONICS |

| Stages | 4 |

| Membrane Type | Thin Film Composite (TFC) |

| Type | Reverse Osmosis |

| pH Range | 11 |

Space requirements for membrane element removal and housing changes.

Feed water source pressure and quantity requirements for RO machine operation.

Instructions for installing CIP valves in feed, permeate, and concentrate lines.

Proper drain line connection for concentrate outlet and maximum back pressure.

Requirements for feed water quality to ensure permeate quality and membrane life.

Methods for transporting permeate and using pressure correction factors.

Details on single-phase and three-phase electrical supply requirements for the RO machine.

How to remotely control the Economy and Deluxe models using float switches.

Pretreatment checks, start-up preparation, and step-by-step start-up process.

Explanation of the Autoflush timer function and how it increases cross flow for flushing.

Step-by-step guide to calibrate the conductivity probe using a standard solution.

Manual flushing for Economy models and automatic flushing for Deluxe models.

Pre-filter cartridge replacement and membrane element cleaning recommendations.

Cautionary notes and step-by-step guide for replacing membrane elements.

Common causes and solutions for low operating pressure.

Causes and solutions for low permeate flow rate and concentrate flow problems.

Causes and solutions for excessive pressure drop and declining rejection.

Causes and solutions for unit not operating or electrical shutdowns.