913218/CP0307 66 PRINTED IN U.S.A.

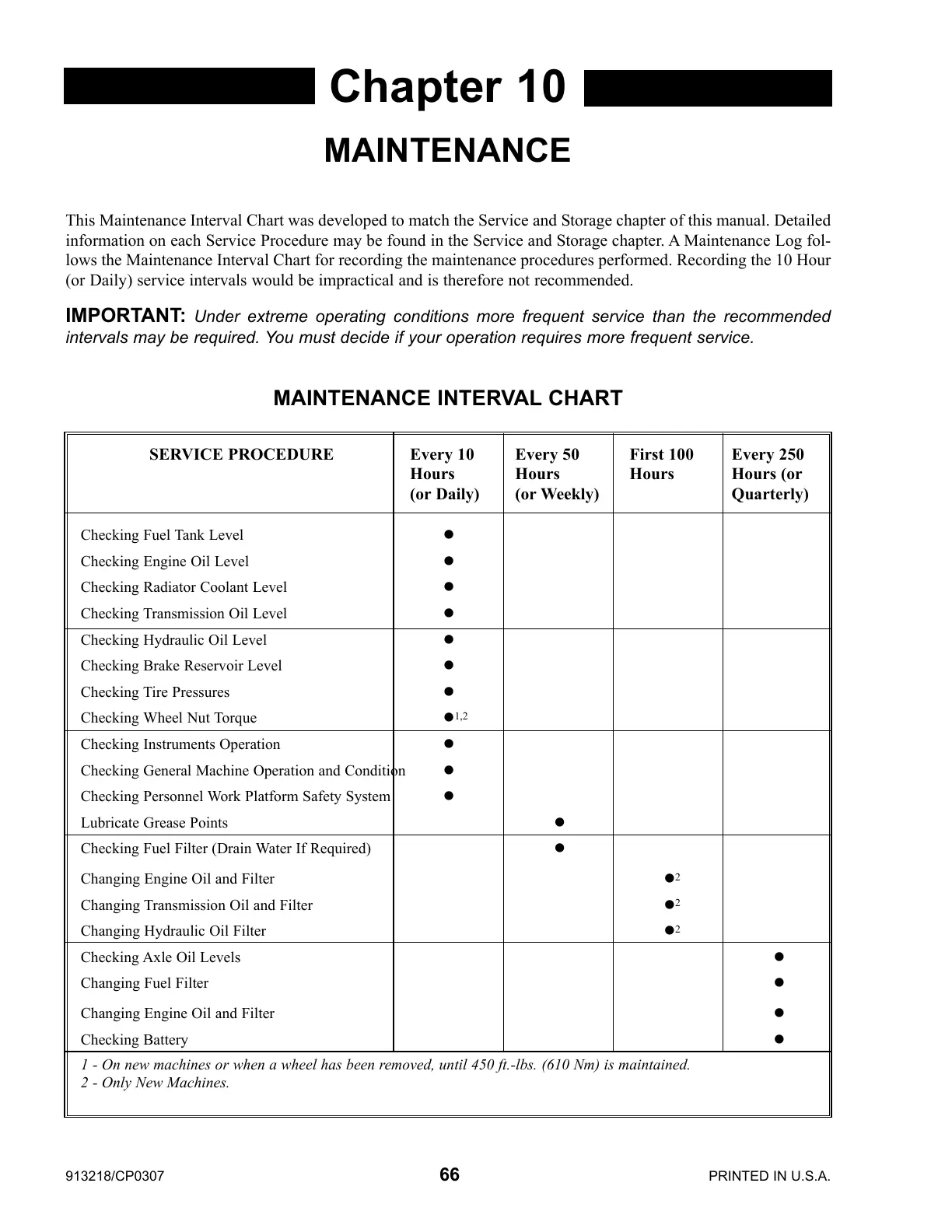

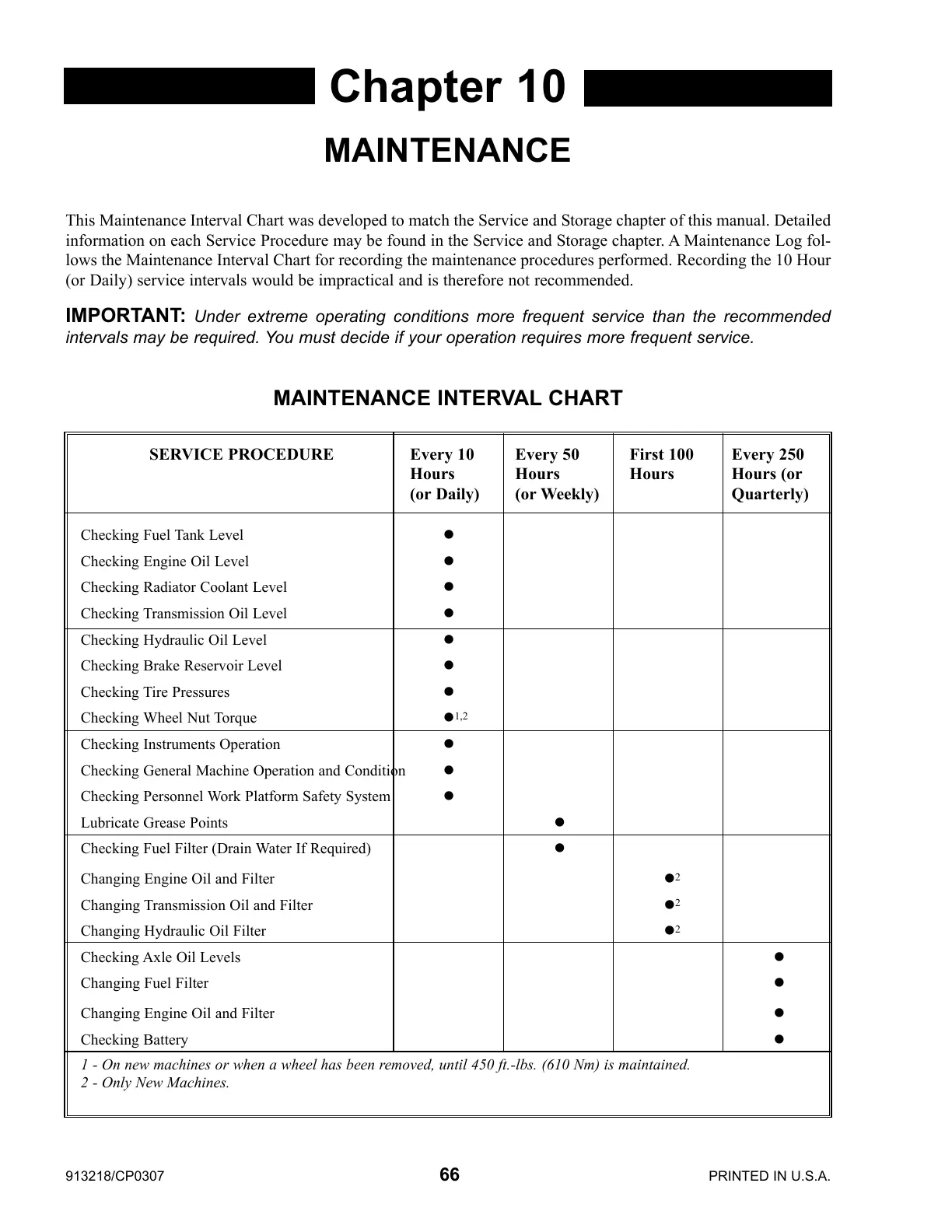

This Maintenance Interval Chart was developed to match the Service and Storage chapter of this manual. Detailed

information on each Service Procedure may be found in the Service and Storage chapter. A Maintenance Log fol-

lows the Maintenance Interval Chart for recording the maintenance procedures performed. Recording the 10 Hour

(or Daily) service intervals would be impractical and is therefore not recommended.

IMPORTANT: Under extreme operating conditions more frequent service than the recommended

intervals may be required. You must decide if your operation requires more frequent service.

Chapter 10

MAINTENANCE

SERVICE PROCEDURE Every 10 Every 50 First 100 Every 250

Hours Hours Hours Hours (or

(or Daily) (or Weekly) Quarterly)

Checking Fuel Tank Level z

Checking Engine Oil Level z

Checking Radiator Coolant Level z

Checking Transmission Oil Level z

Checking Hydraulic Oil Level z

Checking Brake Reservoir Level z

Checking Tire Pressures z

Checking Wheel Nut Torque z

1,2

Checking Instruments Operation z

Checking General Machine Operation and Condition z

Checking Personnel Work Platform Safety System z

Lubricate Grease Points z

Checking Fuel Filter (Drain Water If Required) z

Changing Engine Oil and Filter z

2

Changing Transmission Oil and Filter z

2

Changing Hydraulic Oil Filter z

2

Checking Axle Oil Levels z

Changing Fuel Filter z

Changing Engine Oil and Filter z

Checking Battery z

1 - On new machines or when a wheel has been removed, until 450 ft.-lbs. (610 Nm) is maintained.

2 - Only New Machines.

MAINTENANCE INTERVAL CHART

Loading...

Loading...