33 / 44

600, 630

Important:

After disassembly, clean all parts

of contamination (do not damage

parts). Check parts for potential

damage, replace if necessary (only

use genuine parts from GEMÜ).

12.2 Removing the diaphragm

Important:

Before removing the diaphragm,

please remove the actuator, see

"Valve disassembly (removing

actuator from body)".

1. Unscrew the diaphragm 2.

2. Clean all parts of the remains of product

and contamination. Do not scratch or

damage parts during cleaning!

3. Check all parts for potential damage.

4. Replace damaged parts (only use

genuine parts from GEMÜ).

12.3 Mounting the diaphragm

12.3.1 General information

Important:

Mount the correct diaphragm

that suits the valve (suitable for

medium, medium concentration,

temperature and pressure). The

diaphragm is a wearing part.

Check the technical condition and

function of the diaphragm valve

before commissioning and during

the whole term of use. Carry out

checks regularly and determine the

check intervals in accordance with

the conditions of use and / or the

regulatory codes and provisions

applicable for this application.

Important:

If the diaphragm is not screwed

into the adapter far enough, the

closing force is transmitted directly

onto the diaphragm pin and not

via the compressor. This will cause

damage and early failure of the

diaphragm and thus leakage of the

valve. If the diaphragm is screwed

in too far no perfect sealing at the

valve seat will be achieved. The

function of the valve is no longer

ensured.

Important:

Incorrectly mounted diaphragm

may cause valve leakage /

emission of medium. In this case

remove the diaphragm, check the

complete valve and diaphragm and

reassemble again proceeding as

described above.

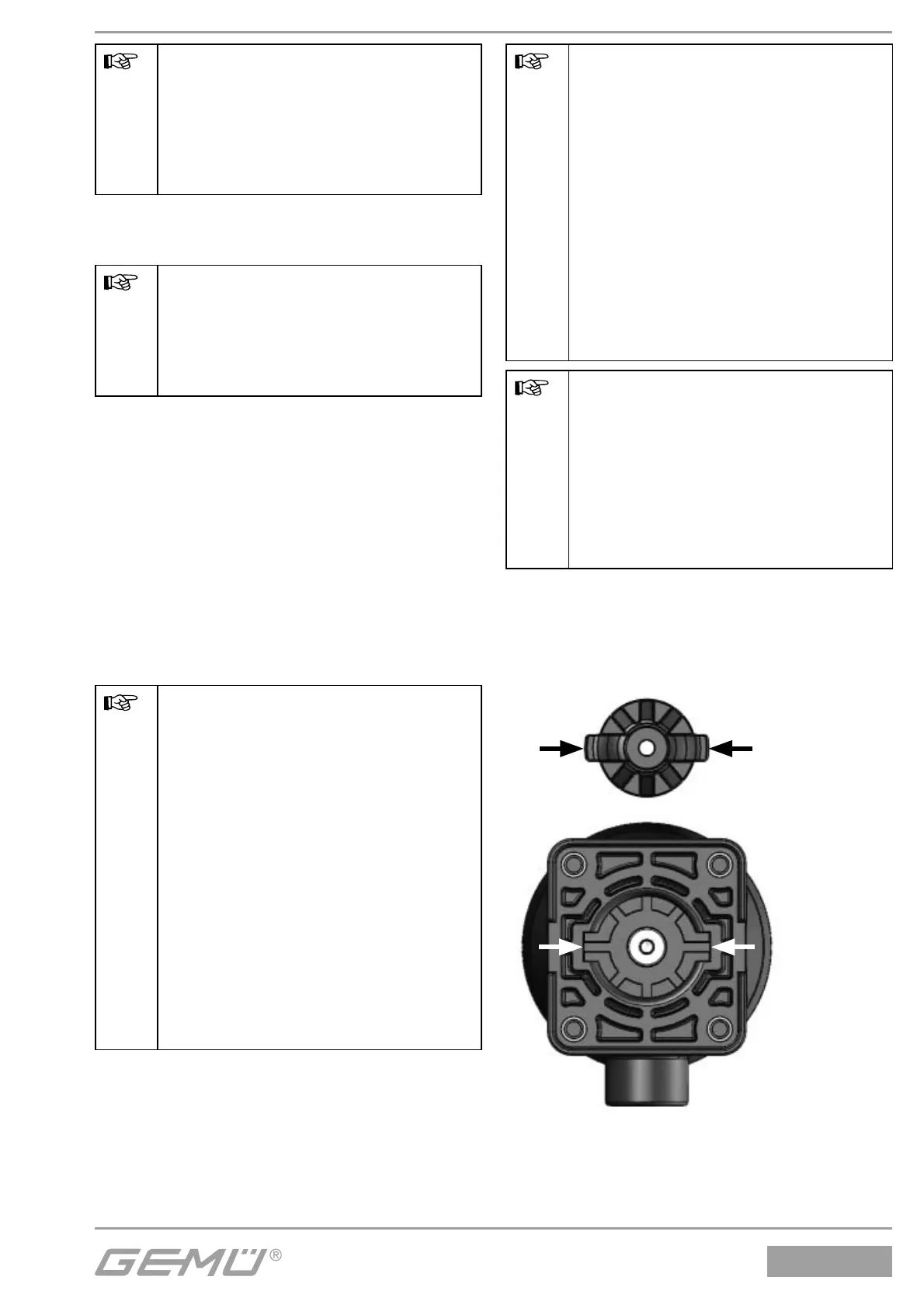

Diaphragm size 10 (only GEMÜ 630):

The compressor is loose. Compressor and

actuator fl ange seen from below:

Compressor -

view from

diaphragm

side

G

Place the compressor loosely on the

actuator spindle, fi t the wings (black

arrows) into the guides (white arrows).

Loading...

Loading...