34 / 44

600, 630

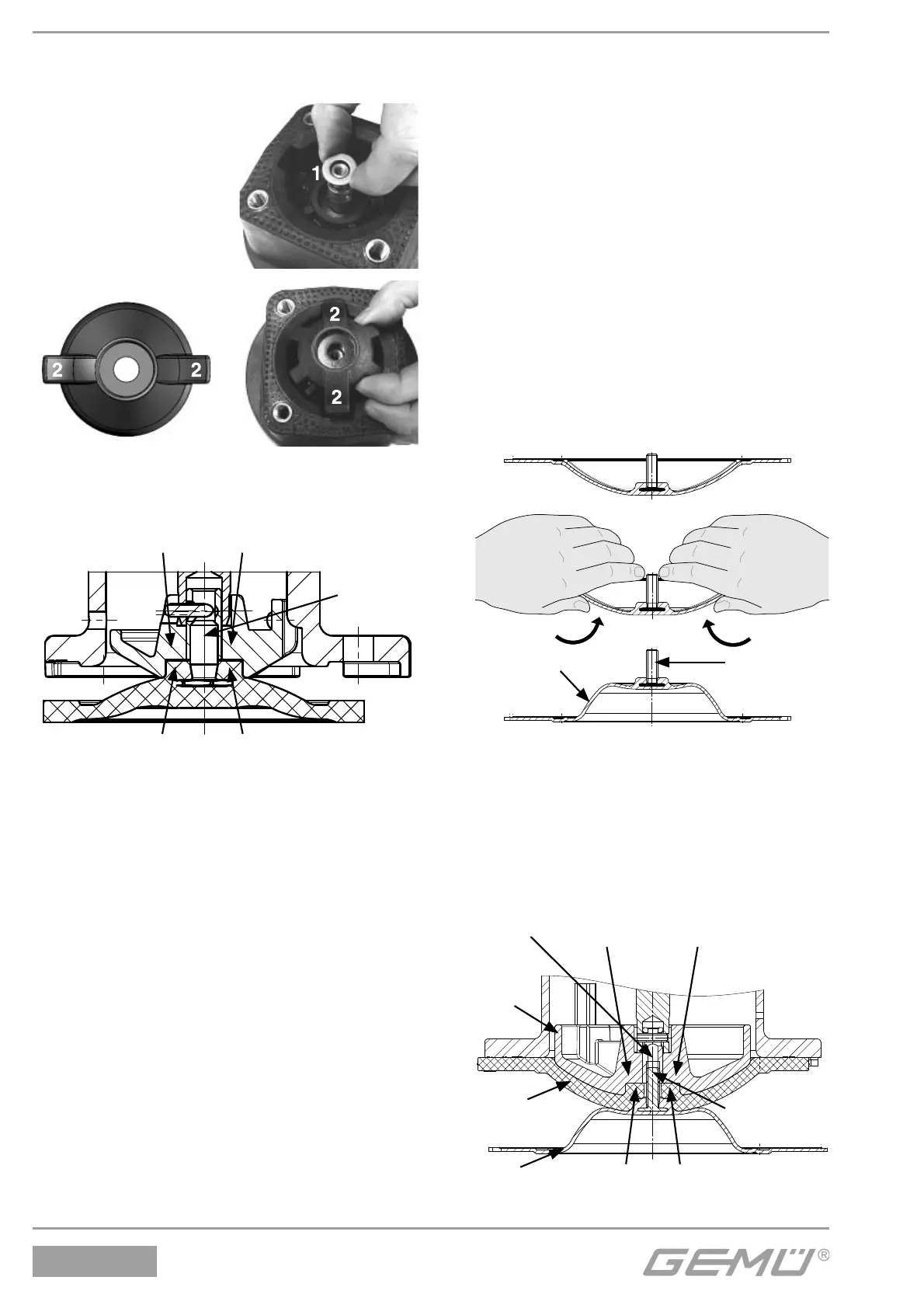

Diaphragm sizes 25 - 50:

The compressor is loose.

G

Place the washer 1

loosely on the

actuator spindle.

G

Place the com-

pressor loosely

on the washer 1,

fi t the wings 2 into

the guides.

DN 32-50

(diaphragm sizes 40-50)

DN 15-25

(diaphragm size 25)

12.3.2 Mounting a concave diaphragm

Diaphragm boss

Recess of compressor

Diaphragm

pin

1. Move actuator A to the closed position.

2. Diaphragm size 10: Place the compressor

loosely on the actuator spindle, fi t the

wings into the guides (see chapter

12.3.1 "General information").

Diaphragm size 25 - 50: Place the

washer loosely on the actuator spindle.

Place the compressor loosely on the

washer, fi t the wings into the guides (see

chapter 12.3.1 "General information").

3. Check if the compressor fi ts closely in the

guides.

4. Screw new diaphragm tightly into the

compressor manually.

5. Check if the diaphragm boss fi ts closely in

the recess of the compressor.

6. If it is diffi cult to screw it in, check the

thread, replace damaged parts (only use

genuine parts from GEMÜ).

7. When clear resistance is felt turn back

the diaphragm anticlockwise until its bolt

holes are in correct alignment with the

bolt holes of the actuator.

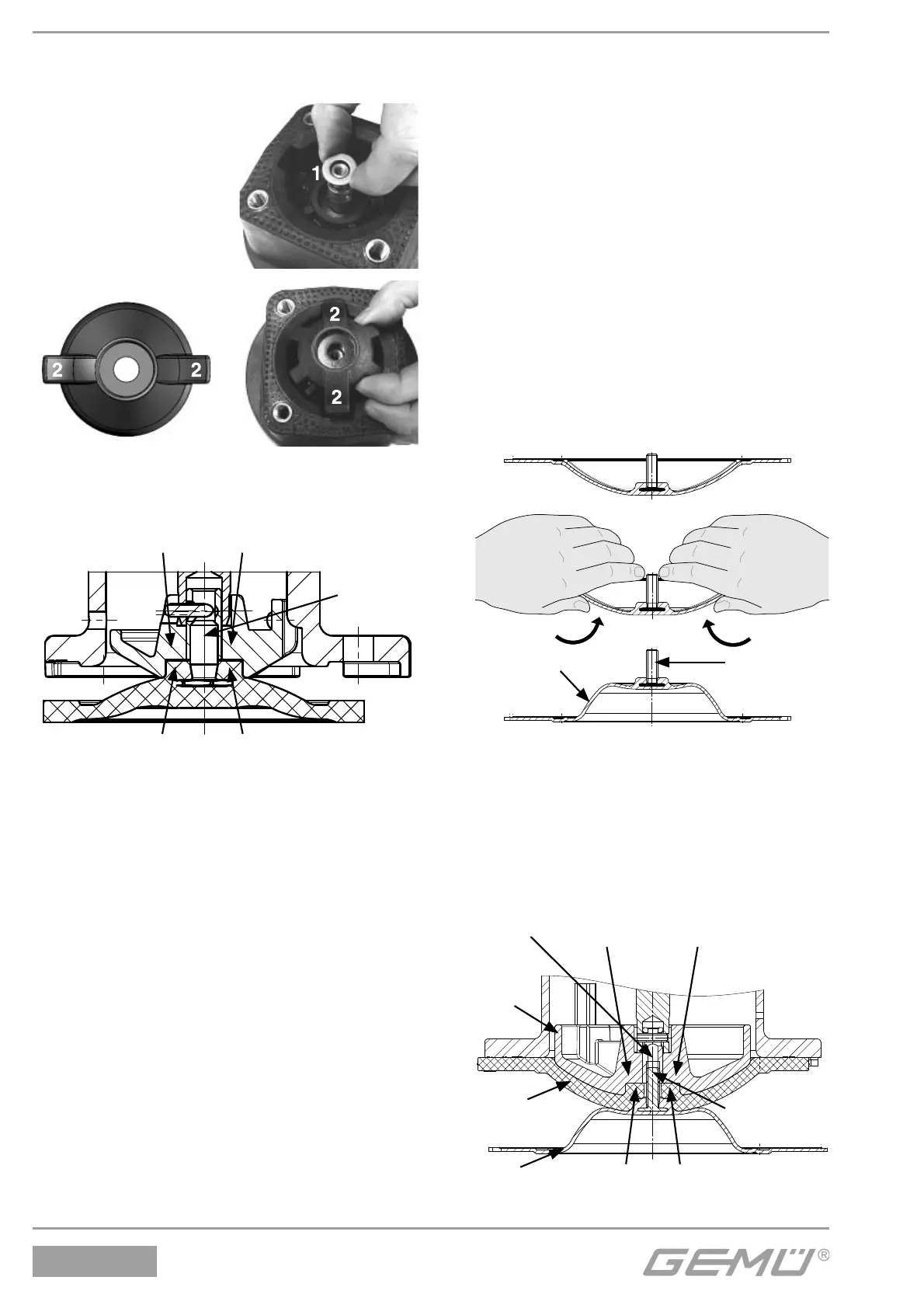

12.3.3 Mounting a convex diaphragm

1. Move actuator A to the closed position.

2. Diaphragm size 25 - 50: Place the washer

loosely on the actuator spindle. Place

the compressor loosely on the washer,

fi t the wings into the guides (see chapter

12.3.1 "General information").

3. Check if the compressor fi ts closely in the

guides.

4. Invert the new diaphragm face manually;

use a clean, padded mat with bigger

nominal sizes.

III.

I.

II.

Diaphragm face Diaphragm pin

5. Position the new backing diaphragm onto

the compressor.

6. Position the diaphragm face onto the

backing diaphragm.

7. Screw diaphragm face tightly into the

compressor manually. The diaphragm

boss must fi t closely in the recess of the

compressor.

Diaphragm boss

Recess of compressor

Com-

pressor

Adapter

Backing

diaphragm

Diaphragm face

Diaphragm pin

Loading...

Loading...