19

221469B

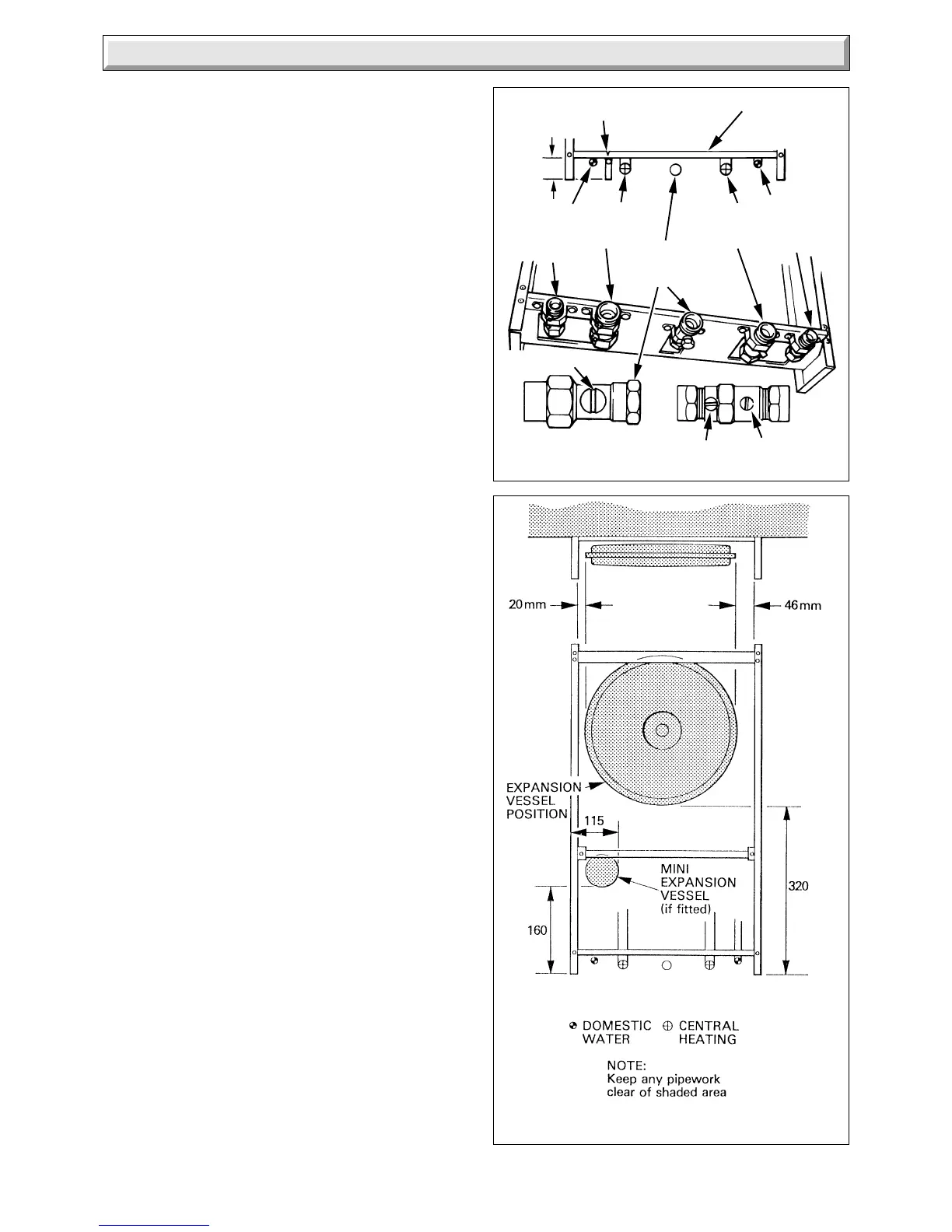

Diagram 8.1

8 Gas and Water Connections

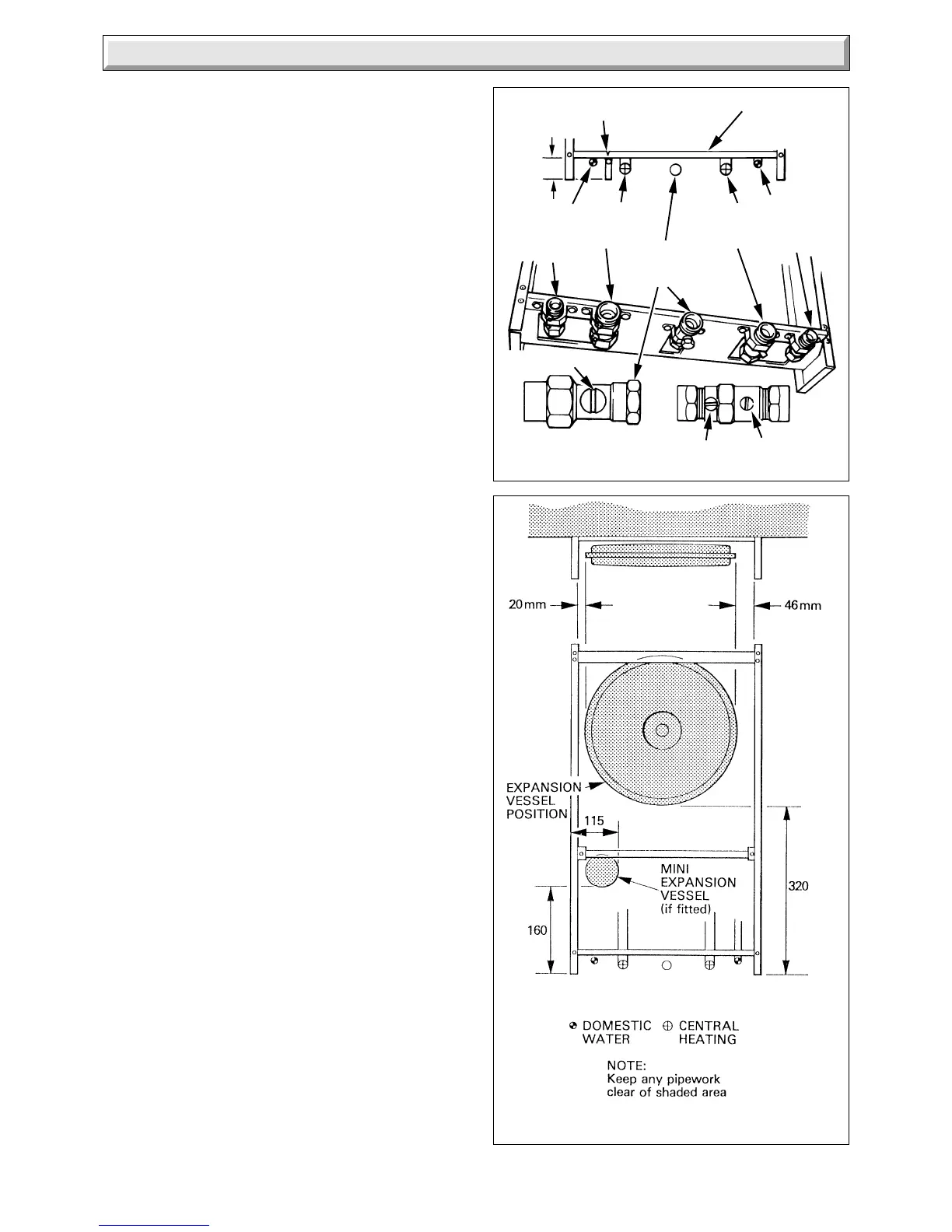

Diagram 8.2

WATER CONNECTIONS

UPWARD ROUTING

OF PIPEWORK

2298

'NOTCH' MARKING POSITION OF

SAFETY VALVE DISCHARGE

BOILER

MOUNTING

FRAME

2297

DOMESTIC

COLD

WATER

SUPPLY IN

CENTRAL

HEATING

FLOW

GAS

SERVICE

COCK

CENTRAL

HEATING

RETURN

DOMESTIC

HOT

WATER

OUT

63

SLOT (CLOSED)

SLOT

(CLOSED)

DRAIN POINT

8.1 Gas Connection

Provision is made for the gas supply to be connected from

below or through the wall at the rear of the boiler, see diagram

8.1 for position.

Refer also to “Gas Supply”, Section 1.8.

Make the gas supply connection to the gas service cock.

Slacken or remove the clip, as preferred, while making the

connection. Do not subject the gas service cock to heat as you

may damage the seals.

8.2 Water Connections

Provision is made for the domestic cold water inlet to be

connected from below or through an internal wall at the rear of

the boiler, see diagram 8.1 for position. Refer also to Section 5

“Domestic Hot Water System”.

Provision is made for the domestic hot outlet, heating flow and

return to be connected from below, through an internal wall at

the rear of the boiler or from above, passing down either side of

the boiler, see diagram 8.2 for clearances. Take care that any

pipework connected from above, within the boiler mounting

frame will clear the expansion vessels.

If necessary, temporarily fit the boiler, refer to Section 10.1,

“Mounting the Boiler”.

Flush out the domestic water and heating system before

connecting the boiler.

Make the connections to the domestic hot water outlet by

straight connector, and the heating system by means of the

isolating valves, see diagram 8.1.

Slacken or remove the clips, as preferred, while making the

connections. Do not subject any of the isolating valves to heat

as you may damage the seals.

Make sure that the drain points on the isolating valves are

positioned towards the front of the boiler, also that the drain and

operating screw heads are accessible.

8.3 Safety Valve Discharge

WARNING. It must not discharge above an entrance or window

or any type of public access area.

A short discharge pipe is supplied loose with the boiler, which

when fitted to the safety valve, will end below the boiler at the

mark between the cold water inlet and the heating flow, for

position and dimension see diagram 8.1.

This must be extended, using not less than 15mm od pipe, to

discharge, in a visible position, outside the building, facing

downwards, preferably over a drain. The pipe must have a

continuous fall and be routed to a position so that any discharge

of water, possibly boiling, or steam cannot create any danger to

persons, damage to property or external electrical components

and wiring.

Note. To ease future servicing it is advisable to use a compression

type fitting to extend the discharge pipe.

Loading...

Loading...