29

221469B

This boiler will be fitted with either a Honeywell or SIT gas

control valve. It can be identified as shown:-

1.1 Servicing or Replacing Parts

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced as

necessary at regular intervals.

The frequency of the servicing will depend upon the particular

installation conditions and usage, but in general once a year

should be enough.

The servicing of this boiler must be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

Unless stated otherwise all parts removed for servicing or

replacing are fitted in the reverse order to removal.

After completing any servicing or renewing of any gas carrying

part, ALWAYS test for gas soundness and carry out functional

checks of controls.

Throw away all used sealing washers, gaskets and “O” rings

when renewing parts. Use the new ones supplied with the

spares assemblies.

1.2 Data Label

The data label is positioned on the inner case and can be seen

when the outer case is removed.

1.3 Isolation of Boiler

Before starting any servicing or the replacement of parts, isolate

the boiler from the electrical supply at the external isolator and

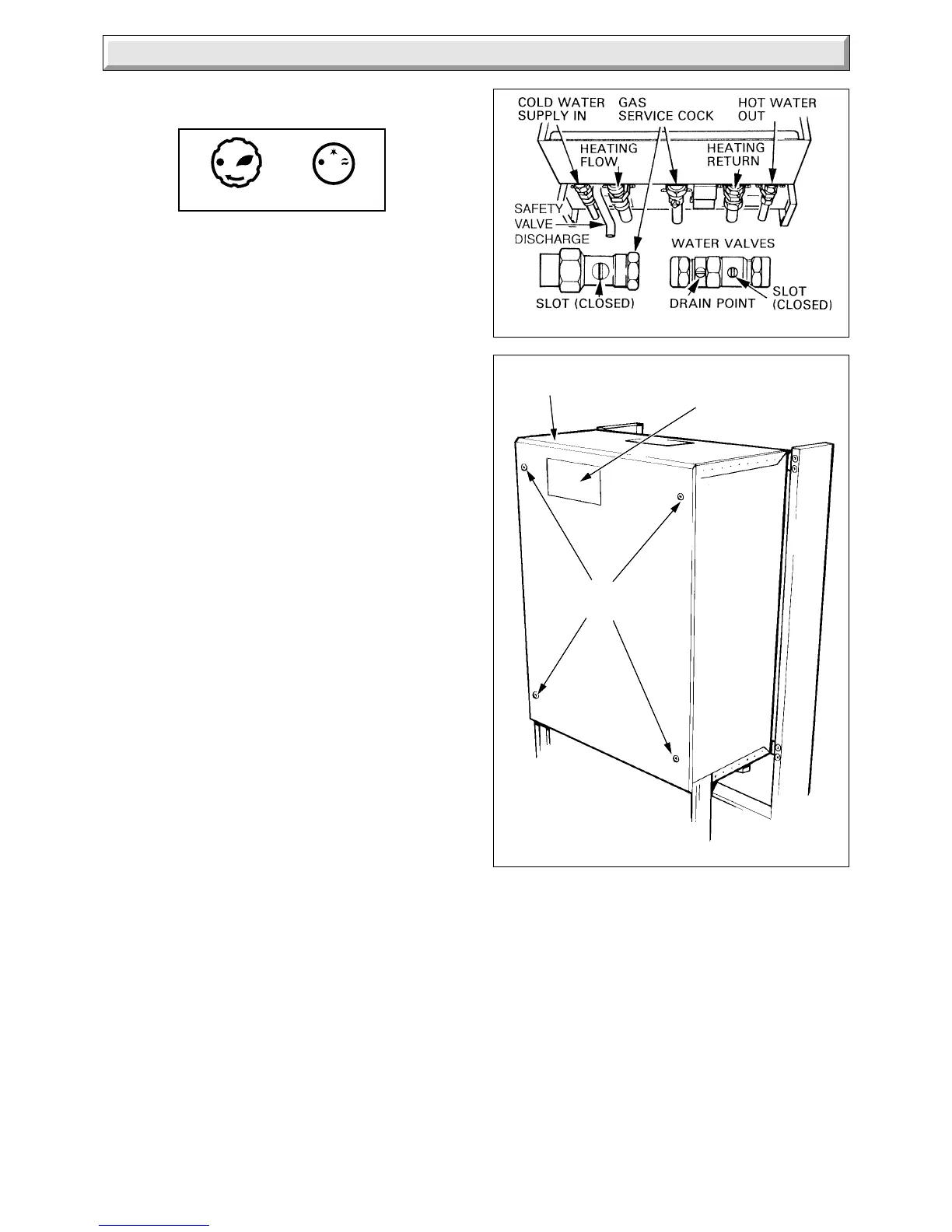

close the gas service cock, see diagram 1.1.

Before disconnecting any water containing part, close the

appropriate isolating valves and release the water pressure

before draining the boiler, see diagram 1.1 and refer to Section

1.6 System Pressure.

1.4 Outer Case Removal

The door opens to the left or right hand side.

The door catch is spring loaded, to open, push the side opposite

to the hinge, then pull.

Remove the two screws securing the outer case then unhook

the case at the top and pull it forwards and off, see diagram 6.1

installation section.

Note: Remove the four securing screws if there is a clock/timer

fitted.

1.5 Cover - Inner Case

Remove the cover of the inner case, secured by four screws,

see diagram 1.2.

1.6 System Pressure and Draining

All water containing parts of the central heating circuit within the

boiler are under the system pressure. Before any parts of this

circuit are disconnected, isolate the central heating valves and

release the pressure by operating the pressure relief safety

valve, see diagram 11.2 installation section.

HONEYWELL

SIT

GAS AND WATER ISOLATING

Diagram 1.1

2793

Diagram 1.2

2797 S

SECURING

SCREWS

INNER CASE

COVER

DATA

LABEL

To gain access to the safety valve knob, remove the outer case,

refer to Section 1.4. Turn the knob in the direction of the arrow.

Drain the boiler heating circuit at the drain points on the

appropriate isolation valves, see diagram 1.1. Make sure that

the automatic air vent is working. Remove the cover of the inner

case, for access, refer to Section 1.5.

All water containing parts of the domestic hot water circuit of the

boiler will be under the supply water pressure. Before any parts

of this circuit are disconnected, isolate the domestic water

valves, open the hot water taps and drain the boiler at the

isolation valves, see diagram 1.1.

After replacing any water containing part of the central heating

system, make up the water loss, vent all air and pressurise the

system, refer to Commissioning in the Installation Instructions.

Check for water soundness and that the safety valve seats

without leaking.

1 General Data

Loading...

Loading...