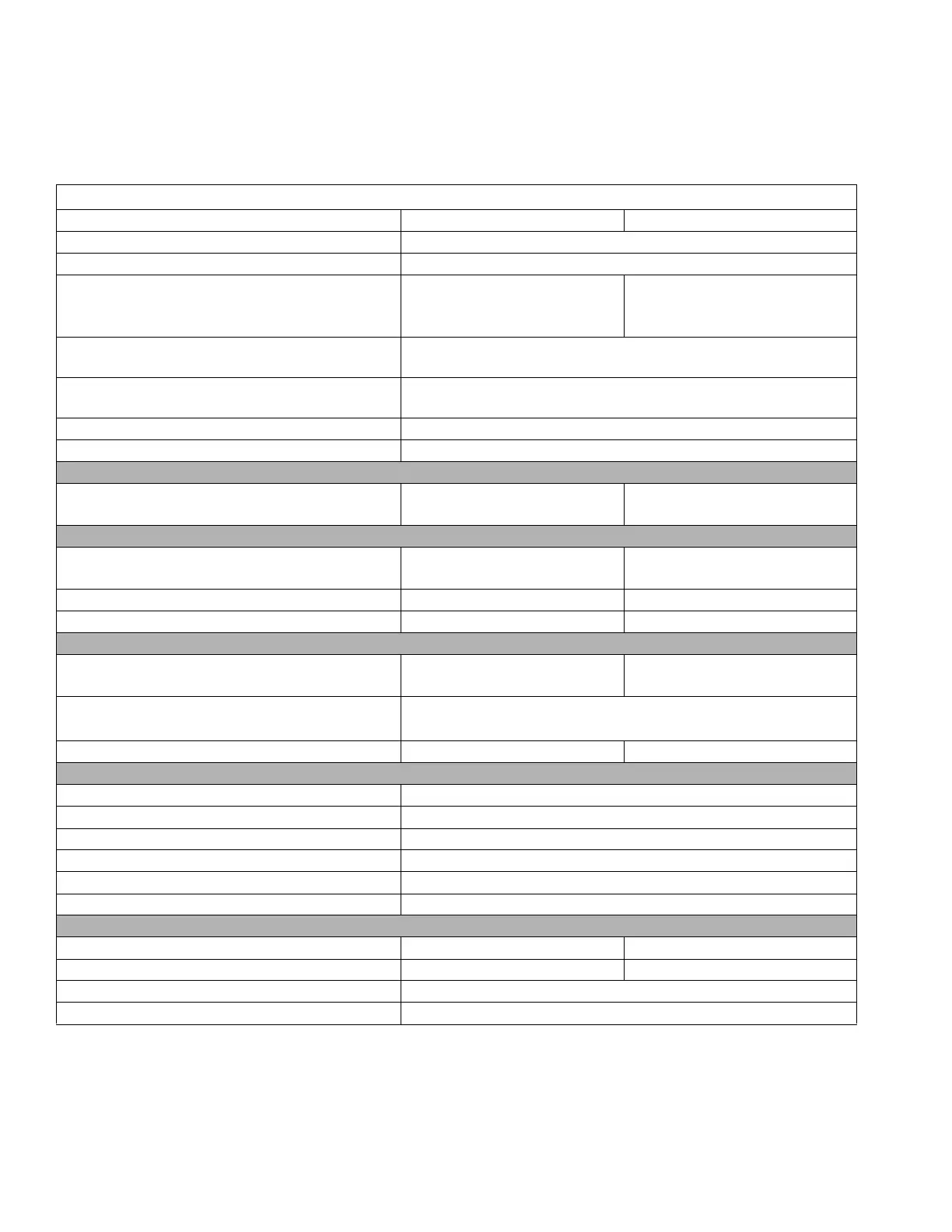

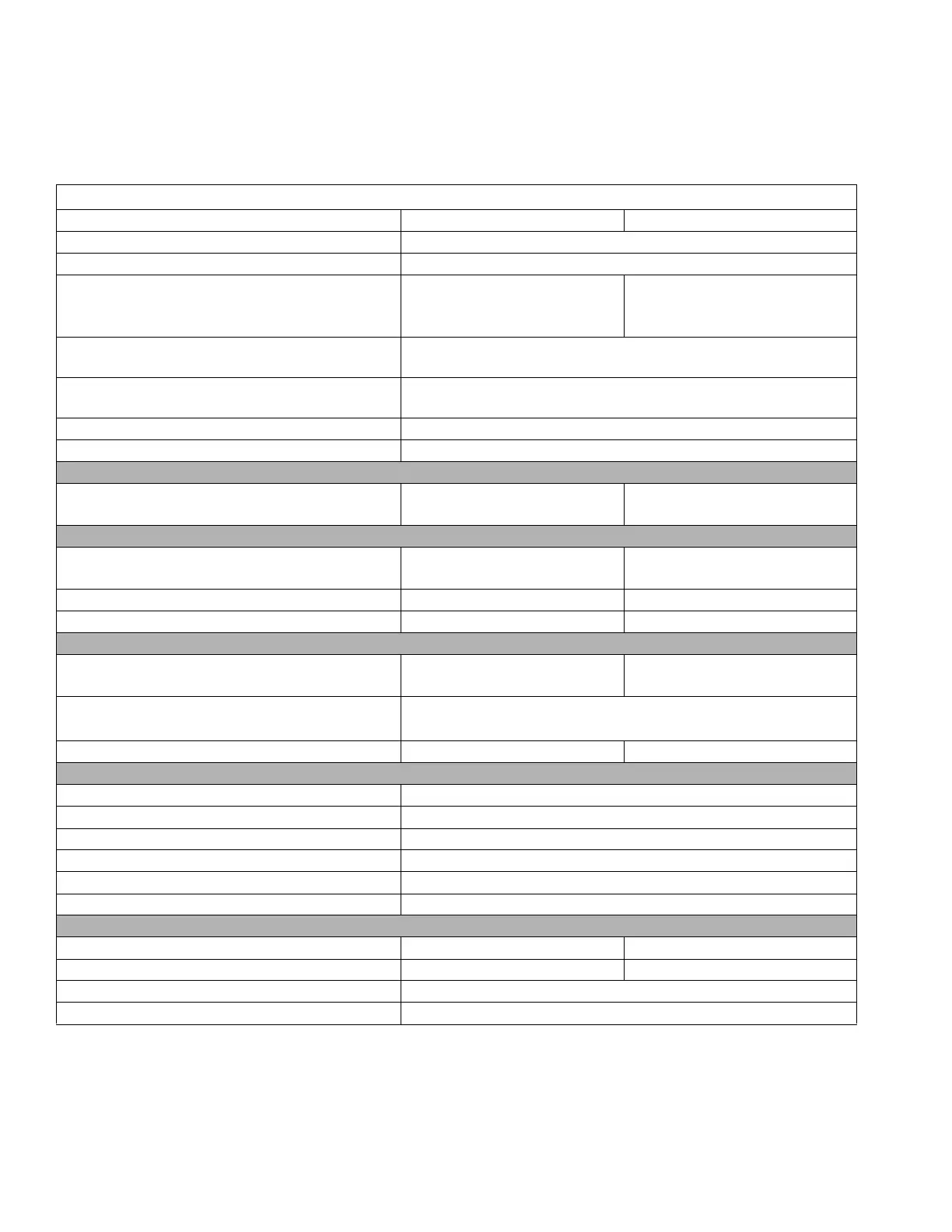

Technical Specifications

28 313292K

Technical Specifications

XM Plural-Component OEM Sprayer

US Metric

Mixed ratio range 1:1-10:1 (in 0.1 increments)

Ratio tolerance range +/- 5%

Flow rates

Minimum*

Maximum

1 qt./min.

3 gal./min.

0.95 liter/min.

11.4 liter/min.

Fluid viscosity range 200-20,000 cps (heavier viscosities can be mixed using heat,

circulation, and/or pressure feeding)

Fluid filtration 60 mesh, (238 micron) standard on pump outlets

(filter assembly not included on some models)

Air inlet 1 npt(f)

Fluid inlets without feed kits 1 1/4 npt(m)

Ambient temperature range

Operating

Storage

32-135 °F

30-160 °F

0-57 °C

-1-71 °C

Maximum fluid working pressure of mixed material

50:1

70:1

5200 psi

6300 psi

35.8 MPa, 358 bar

43.5 MPa, 435 bar

Maximum fluid temperature 160 °F 71 °C

Maximum pump inlet fluid feed pressure 250 psi 1.7 MPa, 17 bar

Maximum pump air set pressure

50:1

70:1

100 psi

90 psi

0.68 MPa, 6.8 bar

0.62 MPa, 6.2 bar

Maximum air consumption at

100 psi (0.7 MPa, 7.0 bar) in scfm (m

^

3/min.)

70 scfm per gpm (1.96 m^3min. per lpm)

Air supply pressure range 50-150 psi 0.35-1.0 MPa, 3.5-10.3 bar

Noise dB(A)

Operating Pressure 70 psi (0.48 MPa, 4.8 bar)

† Sound power 84.8 dB(A)

‡ Sound pressure measured per ISO 3744 95.1 dB(A)

Operating Pressure 100 psi (0.7 MPa, 7 bar)

† Sound power 91.7 dB(A)

‡ Sound pressure measured per ISO 3744 102.0 dB(A)

Environmental conditions rating (indoor/outdoor use)

Altitude Rating Altitudes up to 13,123 ft Altitudes up to 4000 m

Maximum relative humidity To 99% up to 130 °F To 99% up to 54 °C

Pollution degree 11

Installation category 2

* Minimum flow rate is dependent on the material being sprayed and its mixing capability. Test your material specific

to the flow rate.

Loading...

Loading...