Graham Corporation

10

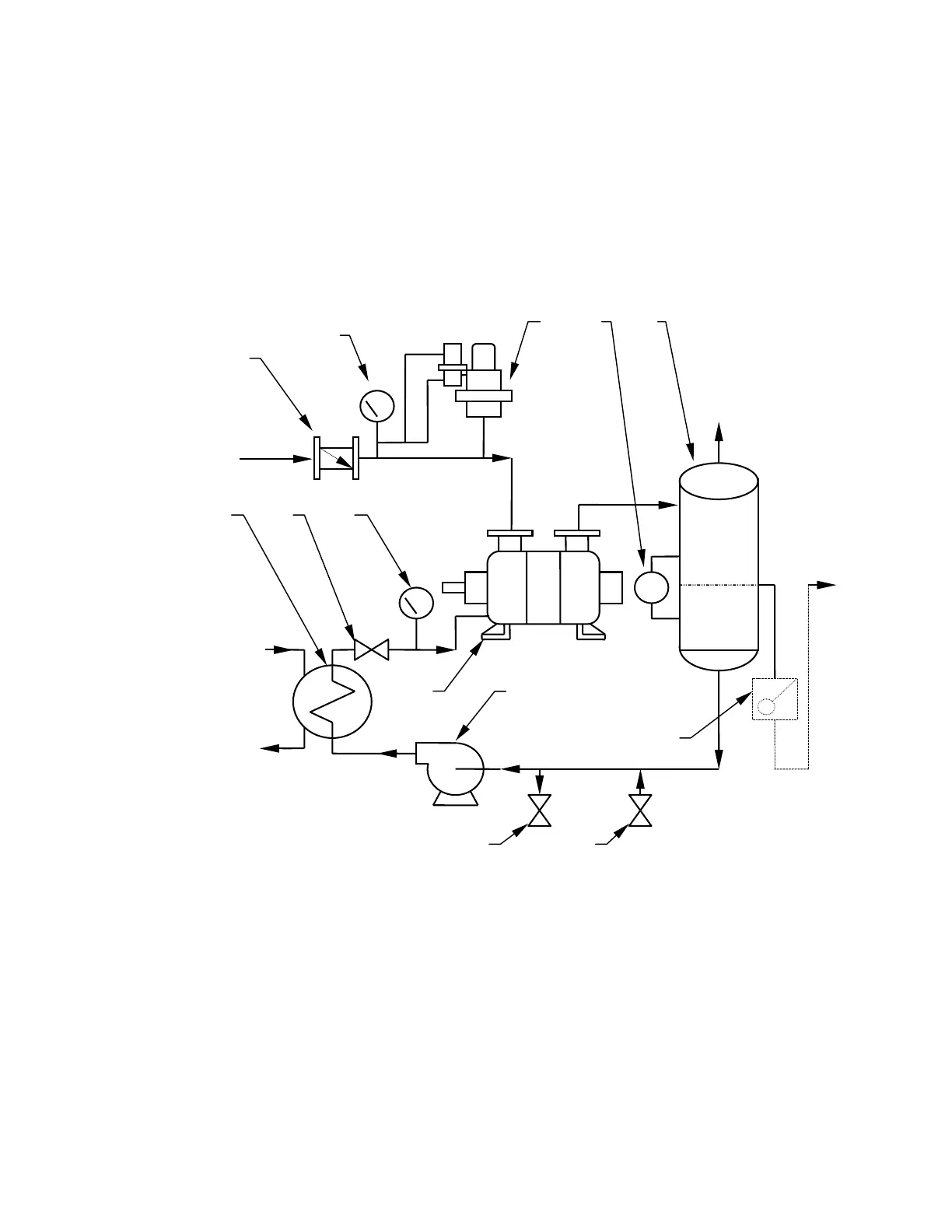

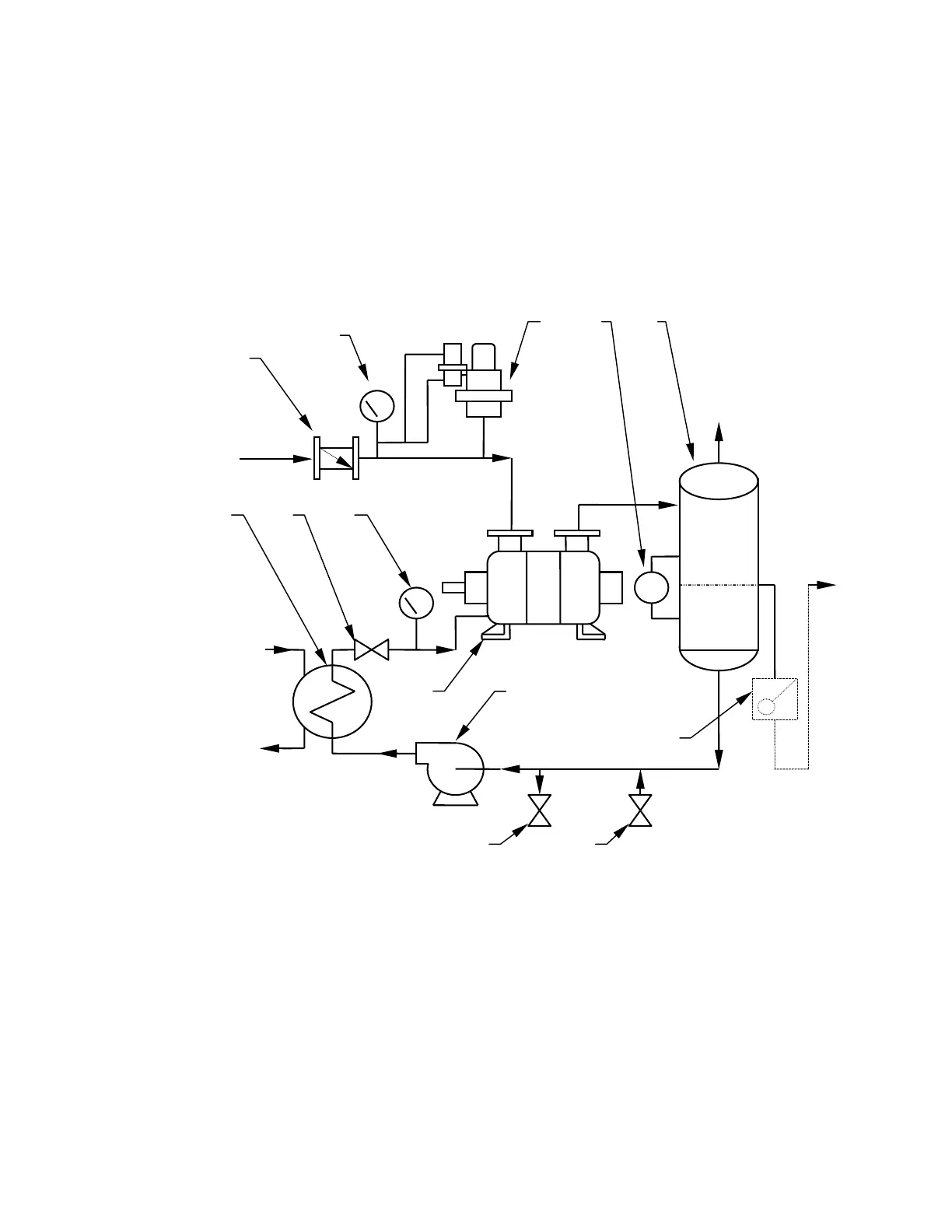

B) Typical Installation of Closed Loop with Total Recovery

This arrangement provides for the total recirculation of the service liquid. A heat exchanger is

added to the system to remove the heat of compression, friction, and condensation from the

service liquid before it is re-introduced to the pump.

The service liquid level in the separator of a total recovery system should be at or slightly

below the centerline of the pump shaft. A provision should be made for a high level overflow.

This will prevent starting the pump while it is full of liquid, which will damage the pump or

overload the motor.

A

E

B

D

L

J

M

K

Drain Make-up

Overflow

Cooling

Liquid

Cooling

Liquid Inlet

Process

Inlet

Gas

Outlet

G H

LG

C

F

A- Inlet Check Valve G- Shut-off or Throttling Valve

B- Pressure Gauge

(vacuum gauge for vacuum

service or compound gauge for compressor

service)

H-

J-

K-

Compound Gauge

Liquid Ring Pump

Recirculation Pump (recommended)

C-

D-

Vacuum Relief Valve

(not required for

compressor service)

Level Gauge

L-

Trap or Loop Seal

(required if dis-

charge pressure is above atmospheric

pressure)

E- Separator M- Drain Valve

F- Service Liquid Cooler N- Make-Up Valve

Closed Loop-Total Recovery

Diagram 2

Loading...

Loading...