Graham Corporation

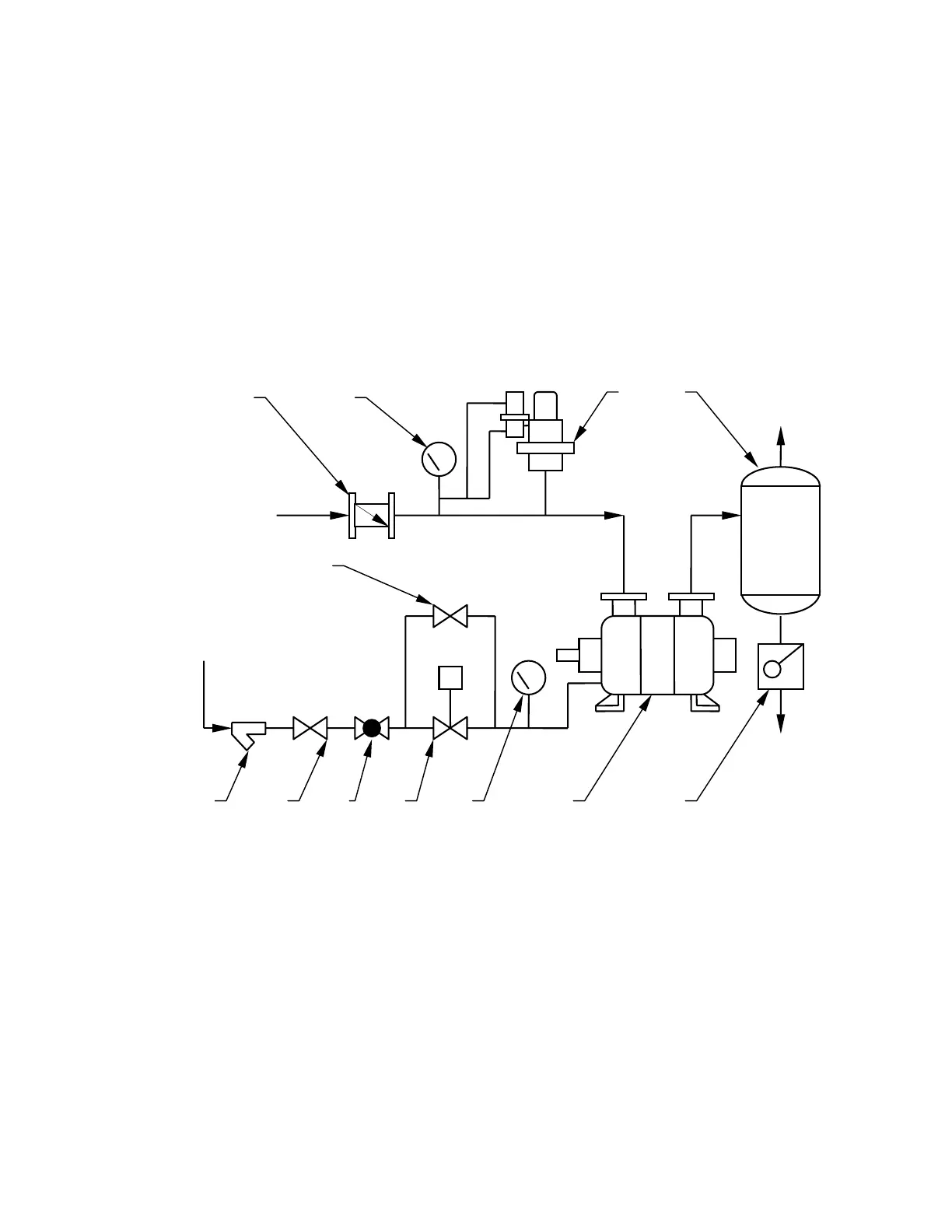

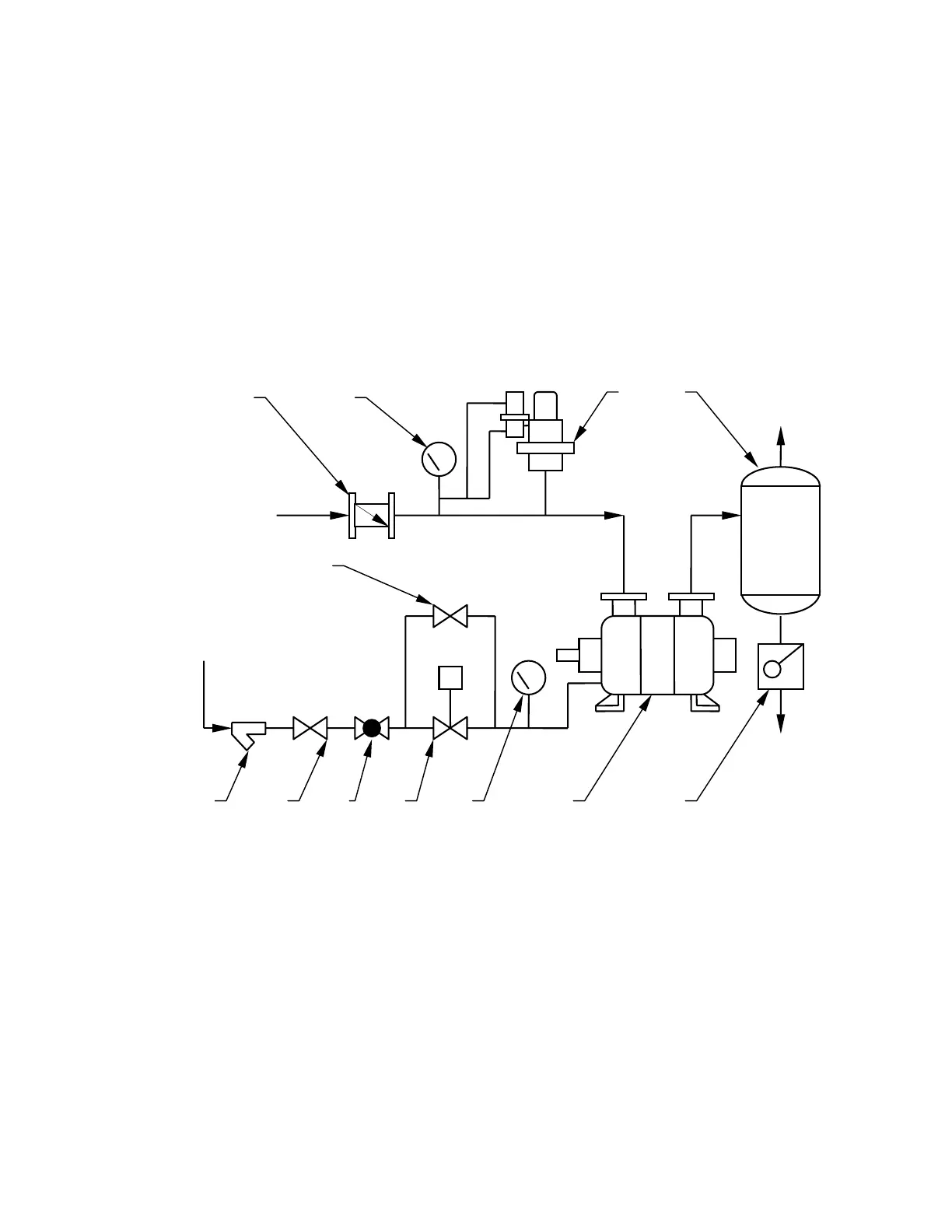

A) Typical Installation of Once Through with No Recovery

The service liquid is piped directly from a supply source to the pump. The liquid is separated

from the gas in the separator and discharged to a drain. No recirculation nor recovery takes

place. This is the most basic arrangement and can be used when service liquid conservation or

contamination is not a concern. A solenoid operated valve provides for flow of the liquid

simultaneously with the pump/motor operation. When the motor stops, the valve closes to

prevent the pump casing from filling with fluid. The by-pass valve is used to pre-fill the pump

at initial start-up only. It also can be used should the solenoid fail. When a manual valve is

used, it must be opened immediately after starting the motor and closed immediately before

turning the motor off.

Process

Inlet

Service

Liquid Inlet

Gas

Outlet

Liquid

Drain

S

A

D

F G H

E

J K

C

M

B

L

A- Inlet Check Valve G- Shut-off Valve

B- Pressure Gauge

(vacuum gauge for vacuum

service or compound gauge for compressor

service)

H-

J-

K-

Regulating Valve

Solenoid Valve

Compound Gauge

C-

D-

Vacuum Relief Valve

(not required for

compressor service)

Separator

L-

M-

Liquid Ring Pump

Trap

(required if discharge pressure

is above atmospheric pressure)

E- By-Pass Valve

F- Strainer

Once Through with No Recovery

Diagram 1

9

Loading...

Loading...