Cassette Type Fan Coil Unit

12

8.3 Electric wiring

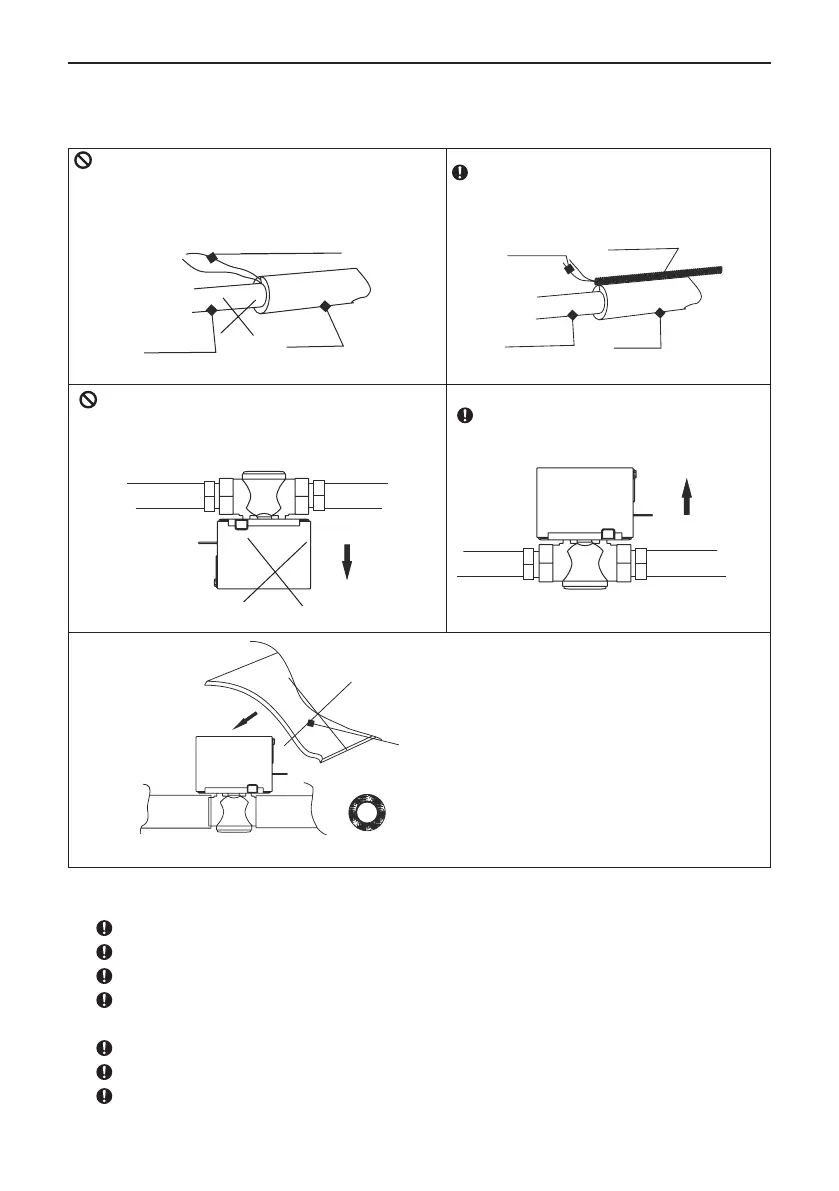

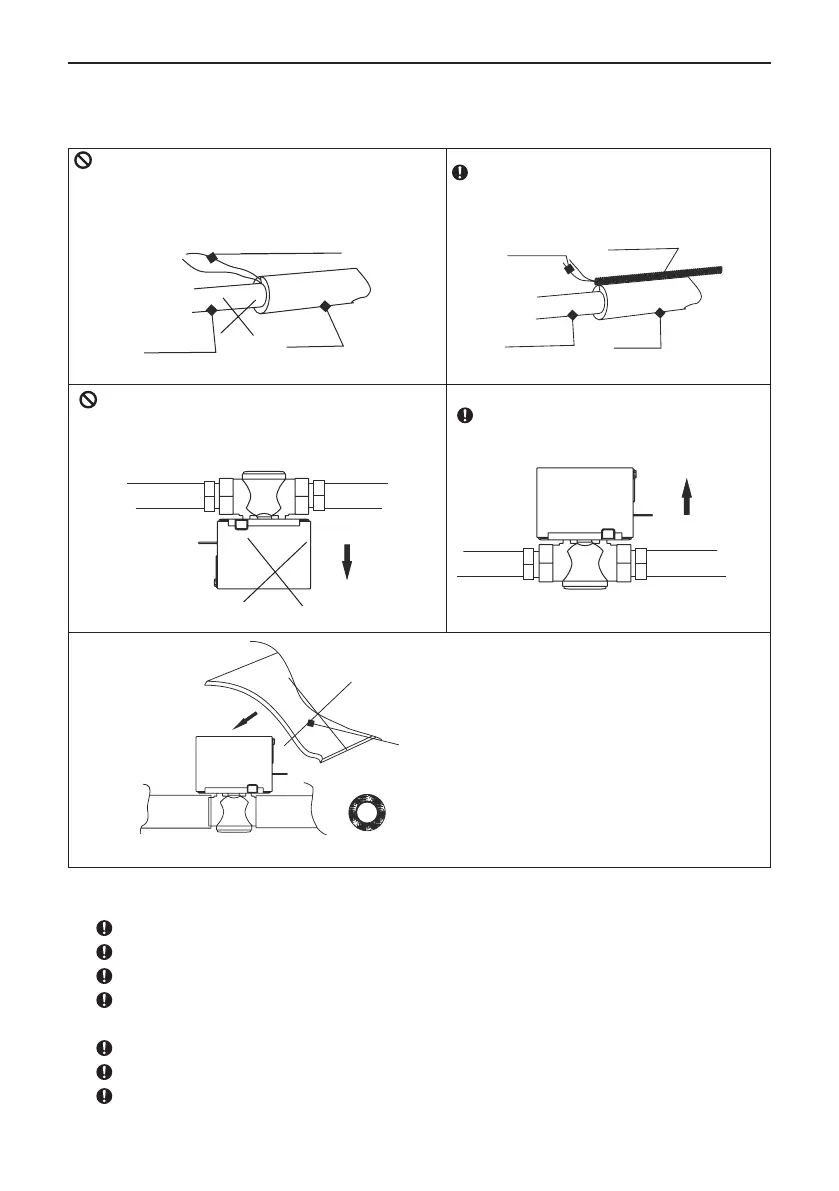

The electric wiring of the valve should be according with the Fig.25

It is prohibited to bind directly the water valve wire

and sponge up with the copper tube, as there would be

probably a short circuit or even electric leakage(as

Fig.20).

Water valve wire

Sponge

Water tube

Fig.20

The right way is letting the water valve wire

go through the pipe sleeve and then binding

the sponge and pipe sleeve up(as Fig.21).

Water valve wire

PVC pipe sleeve

Sponge

Water tube

Fig.21

It is prohibited to put the valve core upside down,

as thiswould allow the condensate water to enter or

damage the valve core and even form a short circuit

which wouldresult in a re hazard(as Fig.22).

Fig.22

The right way is placing the valve core in

the proper position and letting the leading

wire pointing at the unit(as Fig.23).

Fig.23

Sponge

It is prohibited to wrap the whole

valve with sponge, as this would

affect the heat diffusion of the

valve core and probably pose a

re hazard(as Fig.24).

Fig.24

9 Electric wiring

Before obtaining access to termingls, all supply circuits must be disconnected.

All eld supplied parts and meterials must comform to local laws and regulations.

For wiring must be performed by skilled technician.

A circuit breaker capable of shutting down power supply to the entire system and which have

at least 3mm contact seperation in each jole must be install in the xed wiring.

Earth properly.

Waring must conform to national laws and regulations.

The xed wiring must be installed with a protector with not more than 30 mA leakage current.

Loading...

Loading...