English (GB)

4

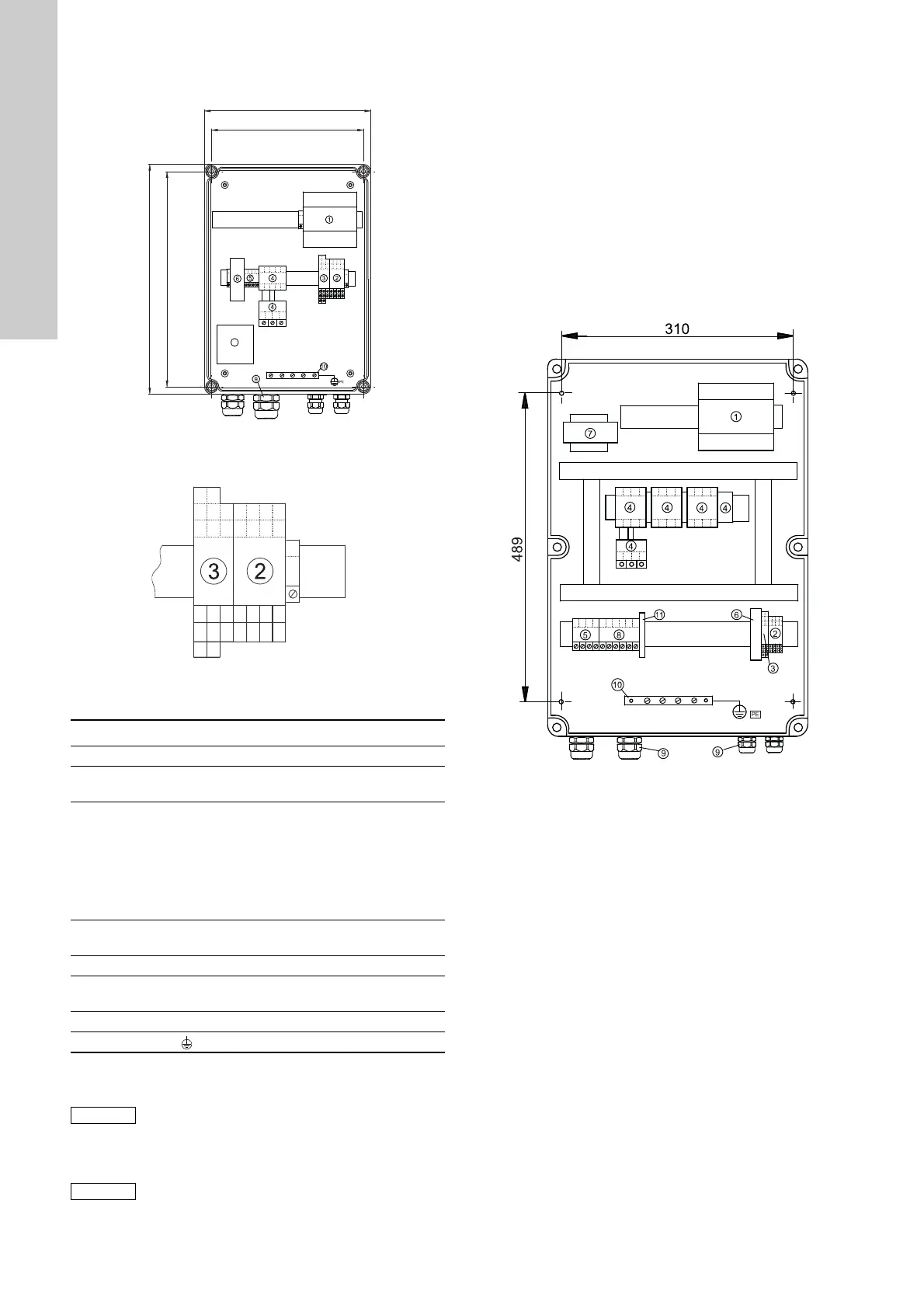

Figure 1 shows the internal construction of the LC 108 for

direct-on-line starting.

Fig. 1

Figure 2 shows the terminals listed under positions 2 and 3.

Fig. 2

Key to the symbols in figs 1 and 2:

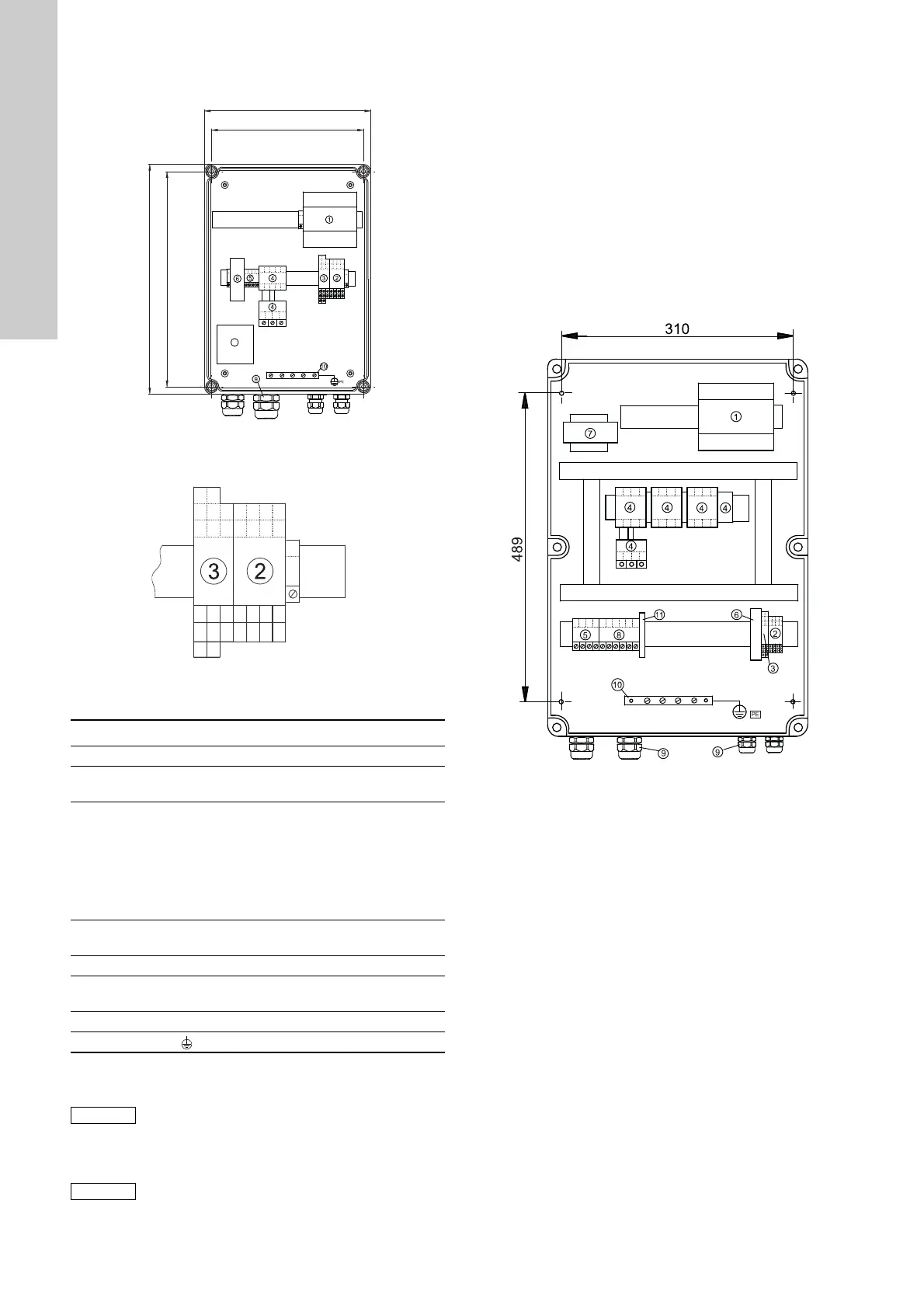

3.3 Mounting of LC 108 for star-delta starting

Before mounting, remove the transport protectors, if any, from

inside the cabinet.

Mount the LC 108:

• on a plane wall surface,

• with the Pg cable entries pointing downwards (additional Pg

cable entries, if required, must be fitted in the bottom plate of

the cabinet),

• with four screws through the mounting holes in the back plate

of the cabinet, see fig. 3. The mounting holes must be bored

with a 4 mm bore. Fit the screws into the mounting holes and

tighten securely. Fit the plastic caps supplied with the

controller on the screws (IP65).

Figure 3 shows the internal construction of the LC 108 for

star-delta starting.

Fig. 3

TM01 6867 2308TM01 6868 2308

Pos. Description

1 Module CU 211.

2

Terminal block for level inputs

(11-12, 21-22, 31-32, 41-42).

3

Terminal block with:

• input for the PTC resistance/thermal switch of the

motor (T11-T21),

• output for external alarm device for high-level alarm

(H-NC, H-COM, H-NO) (only certain variants),

• output for external alarm device for common alarm

(G-NC, G-COM, G-NO).

4

Motor protection relay (contacts and thermal relay

fitted).

5 Terminal block for electricity supply.

6

Fuse holders for control circuit fuses (1 to 3 depending

on voltage/current variant).

9 Pg cable entries.

10 Earth bar (

PE

).

If the distance between the controller and pit

exceeds 20 metres, it is not advisable to use

electrodes as problems with the signal values sent

back to the controller may arise.

In such cases, it is recommended to use float

switches.

Cables of up to 100 metres can be connected

between the controller and the float switches.

T11 T12

1211

22

32

42

21

31

41

G-NO

H-NO

G-COM

H-COM

G-NC

H-NC

TM01 7872 2308

Loading...

Loading...