English (GB)

16

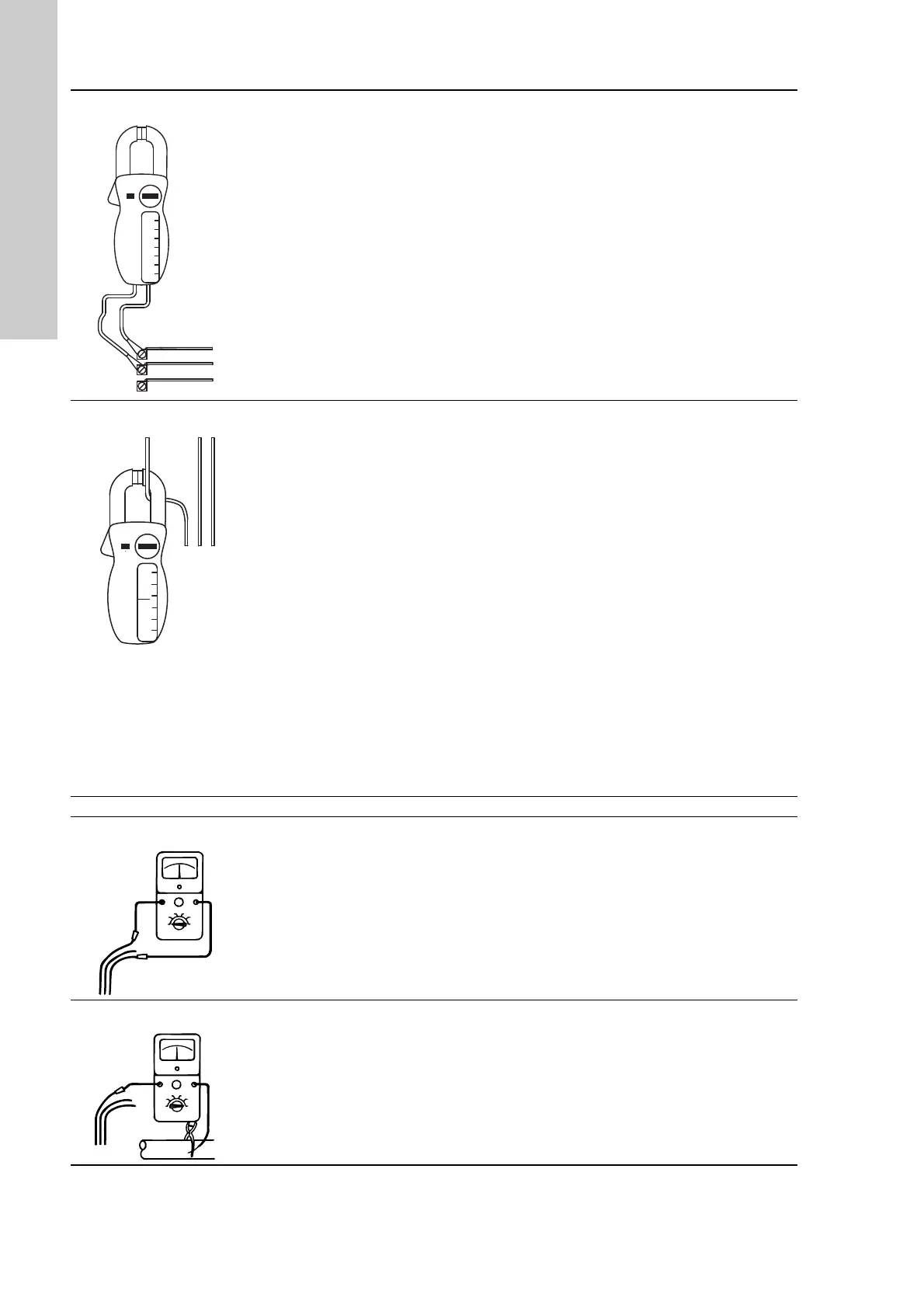

1. Checking the motor and cable

1. Supply voltage

TM00 1371 5092

Measure the voltage between the

phases by means of a voltmeter.

Measure on the terminals where

the submersible drop cable is

connected.

When the motor is loaded, the voltage should be within the

required voltage quality for Grundfos MS submersible

motors which,measured at the motor terminals,is - 10 %/+

6 % of the rated voltage for continuous operation

(including variation in the supply voltage and losses in

cables).

Check also that there is voltage symmetry in the power

supply lines, i.e. the same difference of voltage between

the individual phases.

Large variations in voltage may cause the motor to burn.

Large variations in voltage indicate poor power supply, and

the motor must be stopped until the defect has been

remedied.

2. Current consumption

TM00 1372 5092

Measure the current of each

phase while the pump is

operating at a constant

discharge pressure (if possible,

at the capacity where the motor

is most heavily loaded). For

maximum operating current, see

nameplate.

On three-phase motors, the difference between the current

in the phase with the highest current consumption and the

current in the phase with the lowest current consumption

must not exceed 5 %. If so, or if the current exceeds the

maximum operating current, there are the following

possible faults:

• The contacts of the motor-protective circuit breaker are

burnt.

– Replace the contacts or the control box for

single-phase operation.

• Poor connection of conductors, possibly in the cable

joint.

– See item 3.

• Too high or too low supply voltage.

– See item 1.

• The motor windings are short-circuited or partly

disjointed.

– See item 3.

• Damaged pump is causing the motor to be overloaded.

– Pull out the pump for overhaul.

• The resistance value of the motor windings deviates too

much (three-phase).

– Move the phases in phase order to a more uniform

load. If this does not help, see item 3.

Items 3 and 4: Measurement is not necessary when the supply voltage and current consumption are normal.

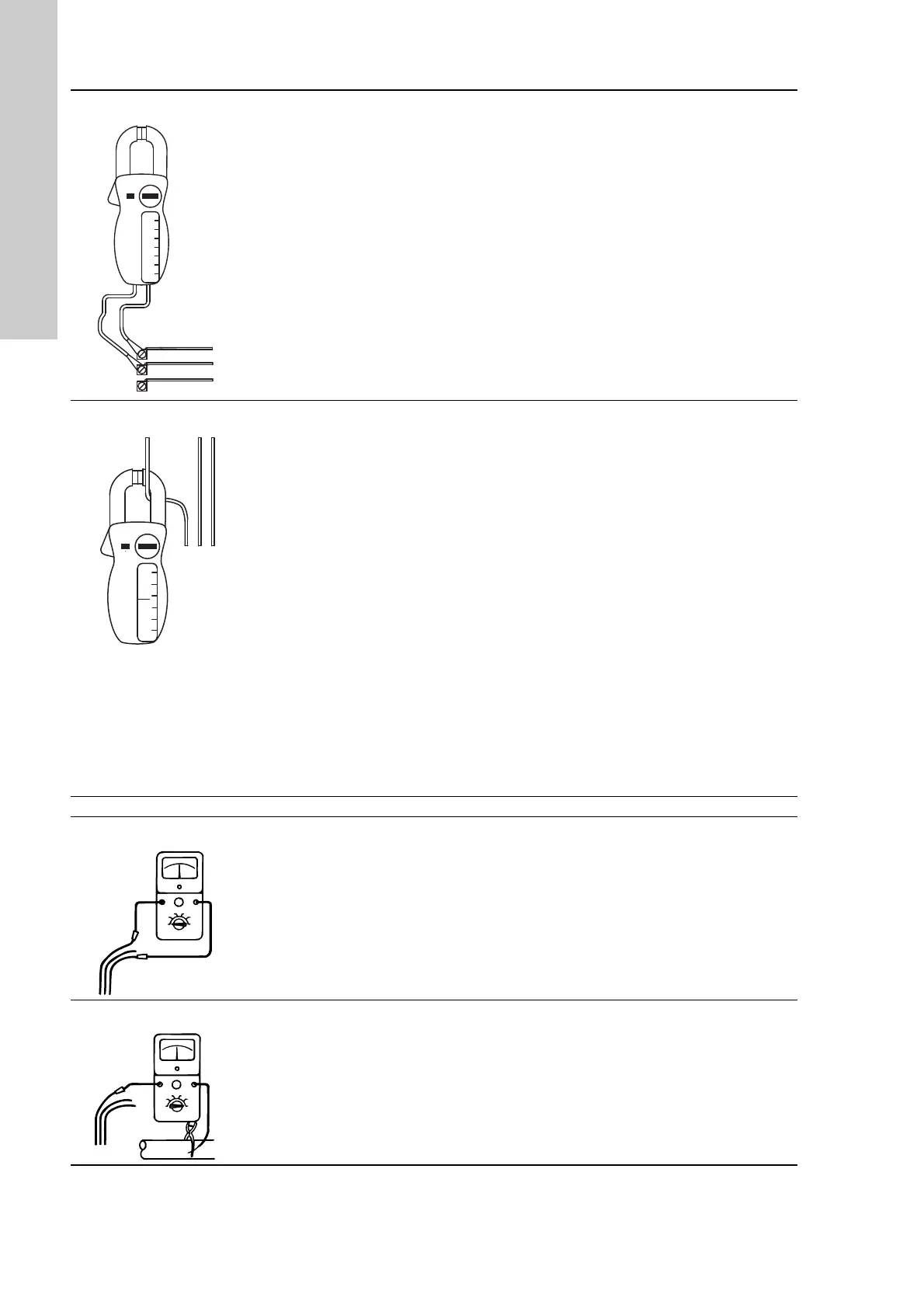

3. Winding resistance

TM00 1373 5092

Disconnect the submersible drop

cable at the motor-protective

circuit breaker. Measure the

winding resistance between the

conductors of the submersible

drop cable. See section

2. Winding resistances.

Note: Include the resistance of

the submersible drop cable. See

section 2.3 Resistance values for

cables.

For three-phase motors, the difference between the

highest and lowest winding resistance must not exceed 10

%. If the deviation is higher, pull out the motor. Measure

motor, motor cable and submersible drop cable separately,

and repair/replace defective parts.

4. Insulation resistance

TM00 1374 5092

Disconnect the submersible drop

cable at the motor-protective

circuit breaker. Measure the

insulation resistance from each

phase to earth (frame). Make

sure that the earth connection is

made carefully.

If the insulation resistance deviates from the values in

section 1.1 Insulation resistance, the motor should be

pulled out for motor or cable repair. Local regulations may

stipulate other values of insulation resistance.

Loading...

Loading...