System analyser

From the preset reference duty point, the pump will

immediately start to analyse the heating pattern.

The system resistance (K

sys

) is logged and based on this

data, a more optimal curve for operation is selected.

Note: K

sys

= m

3

/h to create a system pressure loss of 1

bar.

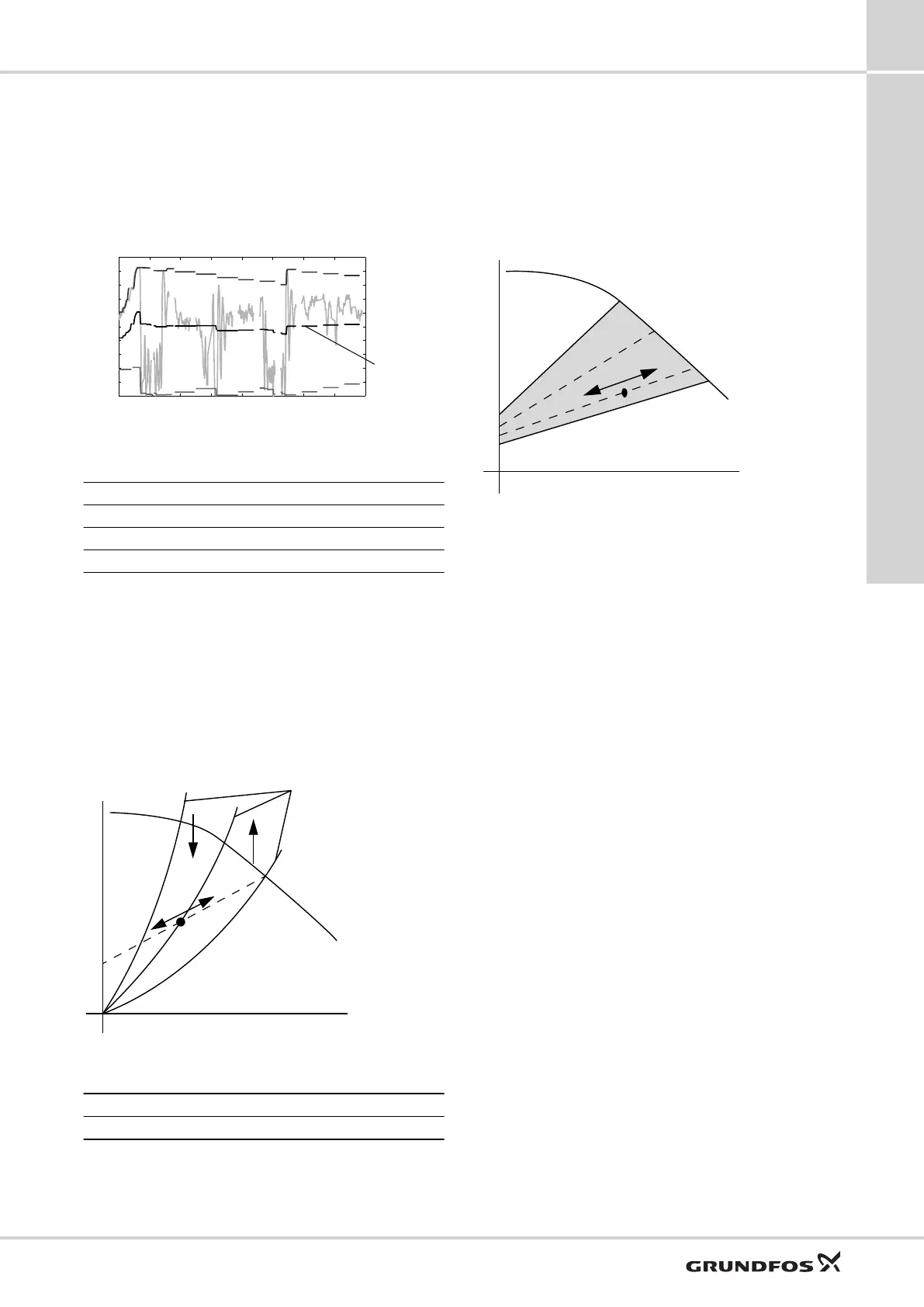

30 30.5 31 31.5 32 32.5 33 33.5 34

0

0.02

0.04

0.06

0.08

0.1

0.12

0.14

0.16

0.18

0.2

Area A

Area B

A

TM060845

K

sys

-values logged for the system analyser

Pos. Description

X-axis Time [days]

Y-axis K-value

A Reference duty point

If the actual duty point deviates from the reference duty

point over time, the pump will automatically adjust its

performance accordingly. If a tendency of operation in

area A is shown, the performance of the pumps is too

high. The pump will then select a lower proportional curve.

In other words, if the requirement of the heating system

exceeds the reference duty point, the pump will choose a

higher proportional pressure curve. Should the

requirement be lower, a lower curve will be chosen.

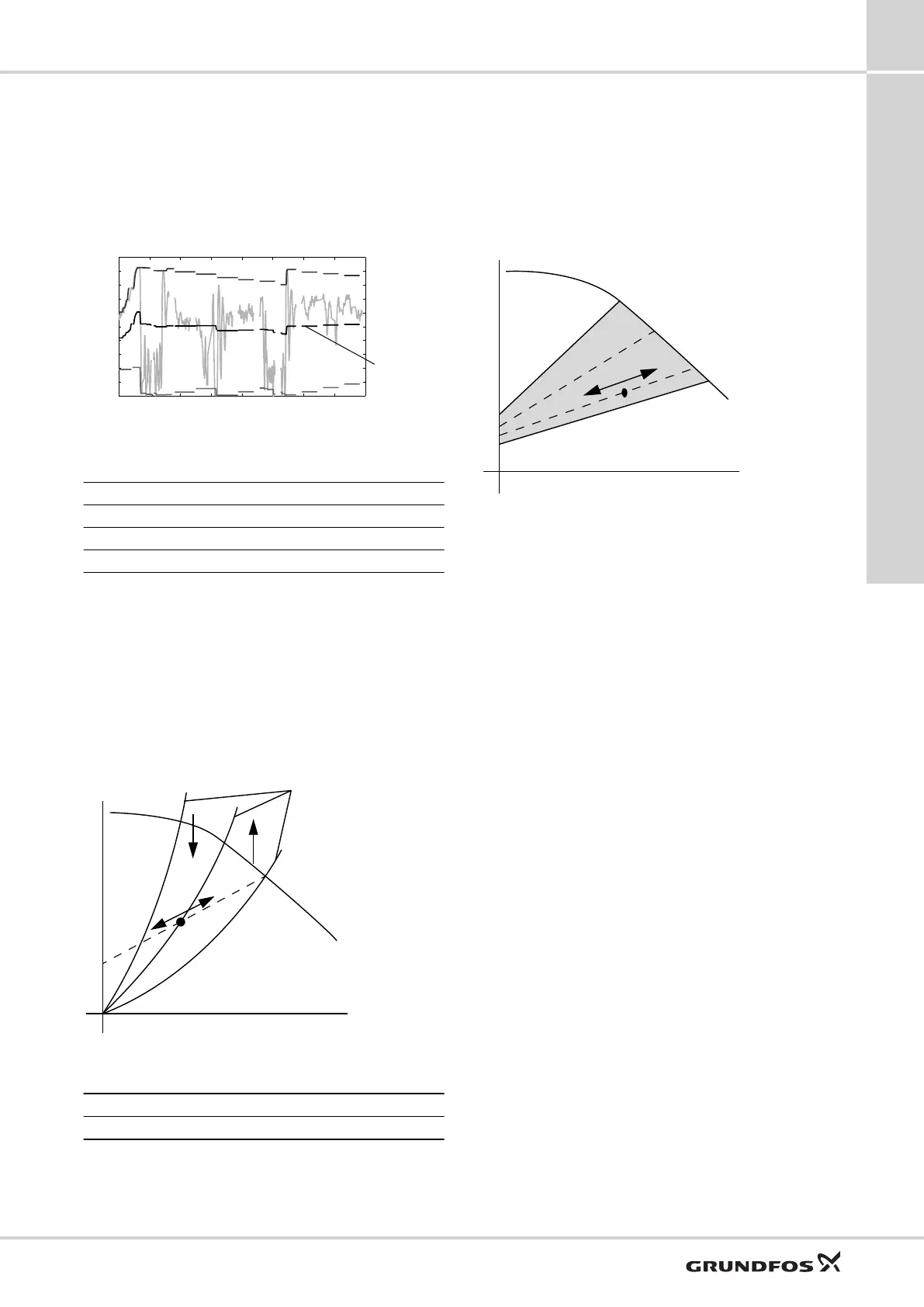

Curve selector

TM060849

Duty point on selected proportional pressure curve

Pos. Description

1 Reference curves

Note: The arrows symbolise the change of the

proportional pressure curve.

New reference setting

When changing the proportional pressure curve setting to

adapt to the requirements of the heating system,

AUTO

ADAPT

automatically sets a new reference duty

point. From the new setting, the process starts over again:

AUTO

ADAPT

will continuously adapt to changes in the

heating pattern.

TM060850

New lower proportional pressure curve

UPM3

8

33

Control modes, operating panel and settings

Loading...

Loading...