Pos. Component Material EN/DIN

15 Pump housing

Cast iron GG15 EN-GJL-150

Stainless steel 1.4308

Composite PA 6.6 30

%GF

Composite PPS 40 %GF

16 Neck ring Stainless steel 1.4301

17 O-ring EPDM

Description of components

The Grundfos UMP3 pumps are of the canned-rotor type

as pump and motor form an integral unit without shaft seal

and with only one gasket for sealing and four screws for

fastening the stator housing to the pump housing. The

bearings are lubricated by the pumped liquid as the rotor

can is filled with water. The focus has been on using eco-

friendly materials as well as on limiting the number of

materials.

Motor description

The efficiency of the three-phase, 4-pole, synchronous,

electronically commutated permanent-magnet (ECM/PM)

motor type is considerably higher compared to a

conventional asynchronous squirrel-cage motor.

The ECM/PM motor is designed according to the canned-

rotor principle. The design of the mechanical motor

components has mainly focused on these features:

• reliable with stainless steel rotor can in one part and

a specific formed EPDM gasket

• simple design meaning as few components as

possible, each with several functions

• high efficient due to permanent magnets and low-

friction bearings.

The motor is cooled by the pumped liquid which reduces

the sound pressure level to a minimum. Being software-

protected, the pump requires no further motor protection.

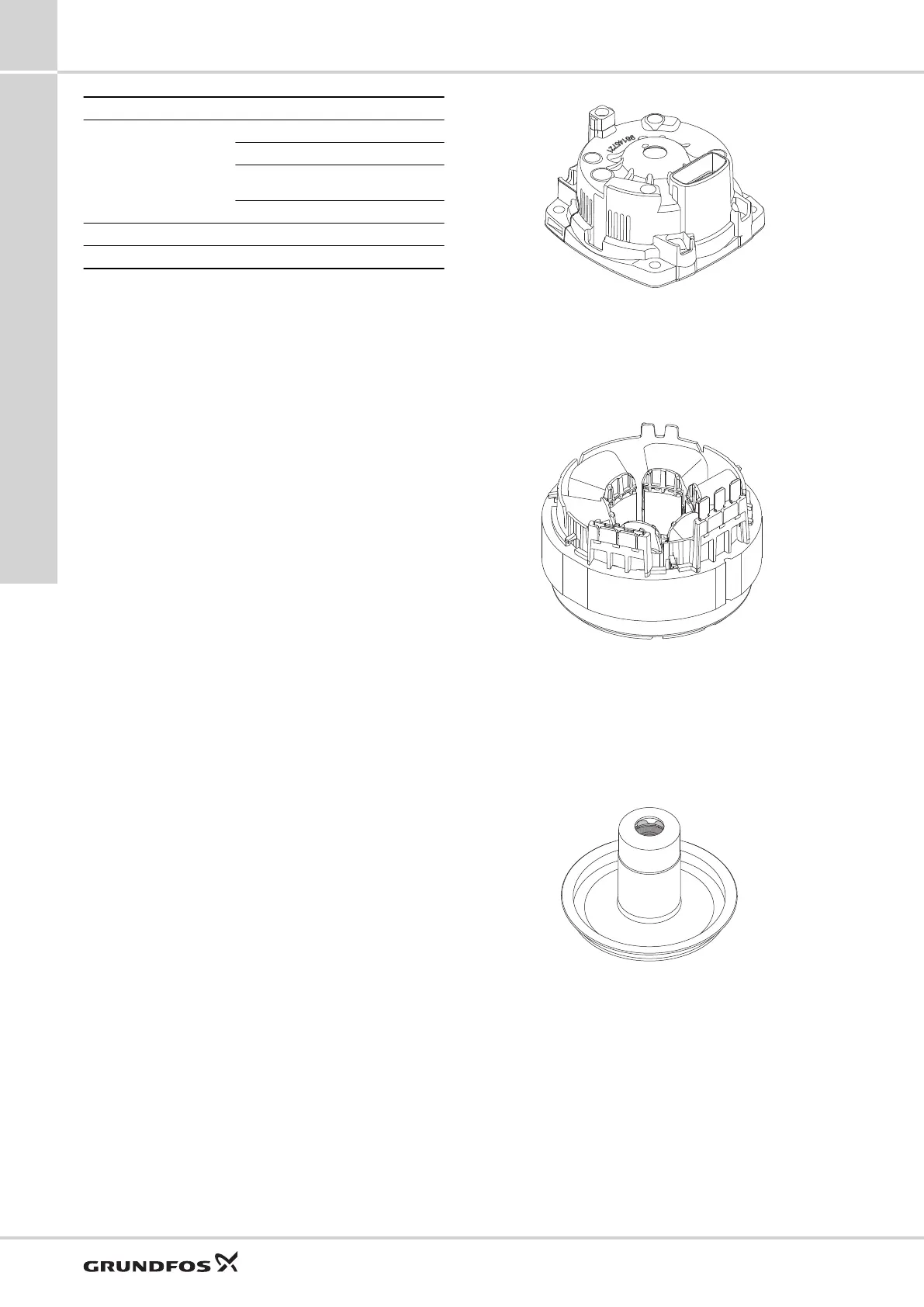

Stator housing

The aluminium die-cast stator housing with four fixing

holes is following the design of the well-accepted

Grundfos UP pumps. It enables easy change of motor

positions by removing the four screws holding the stator

housing and turning the housing to the desired position.

There are two versions: one without drain hole as IP44,

and one with one drain hole in two possible positions as

IPX4D. During operation, the drain hole must always point

downwards. UPM3 is IP44 as standard for non-

condensing applications and IPX4D in UPM3 Solar. As K-

variant for condensing applications, the stator housing

IPX4D version is CED electrocoated.

TM059258

Stator housing

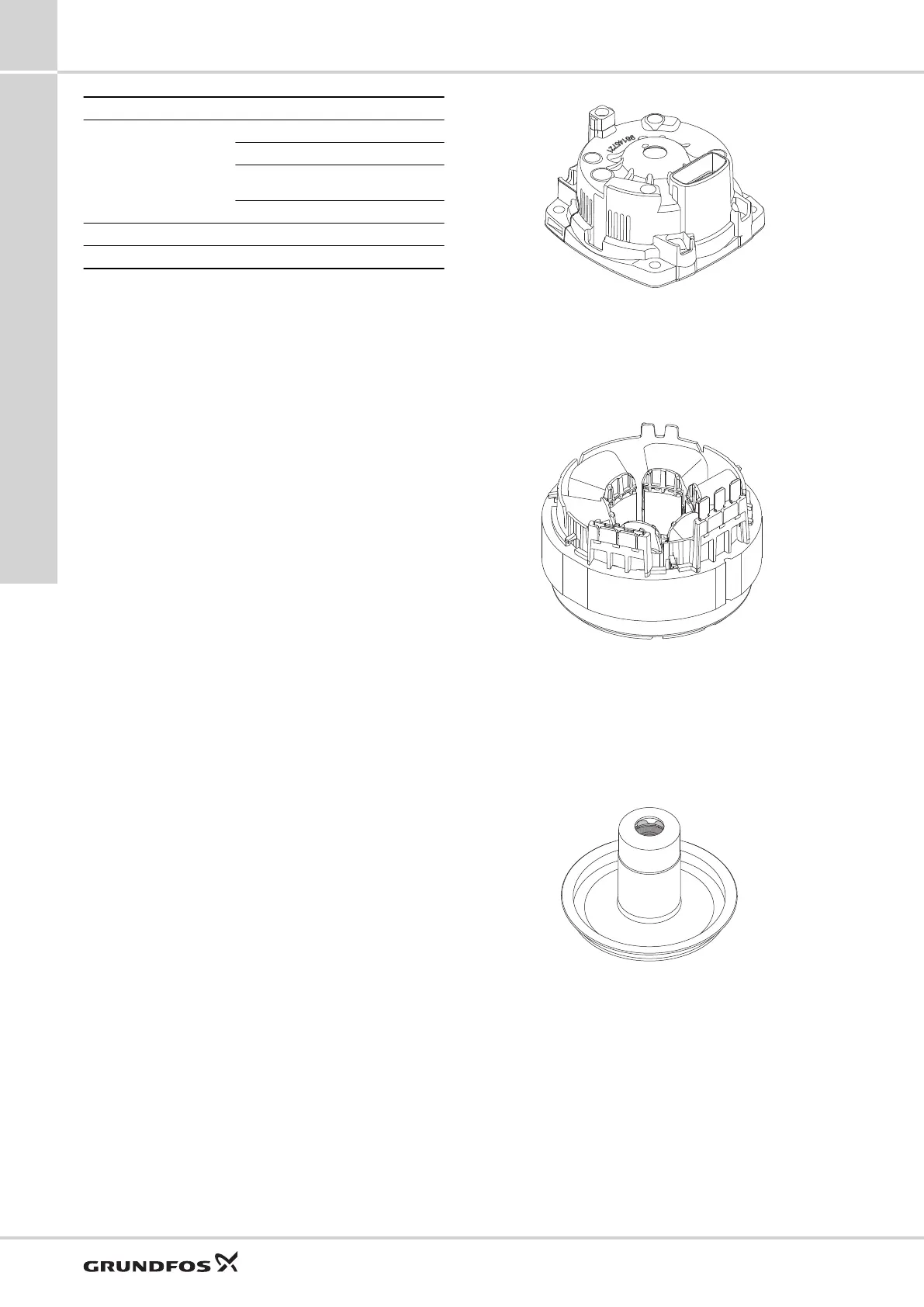

Stator and windings

The UPM3 have a three-phase stator with six concentric

positioned in-slot windings.

TM059260

Stator

Rotor can

The rotor can is drawn out of one sheet of stainless steel.

It contains the ground and honed upper radial bearing. On

top the rotor can has a hole on which the deblocking

device is welded.

TM059247

Rotor can with bearing holder and ceramic bearing

Deblocking device

The deblocking device consists of an axial moving plunger

tightened by an O-ring and pulled back by a spring inside

a stainless steel housing that is welded to the rotor can.

The deblocking device is designed for pumps integrated in

appliances to give access to the shaft from the front of the

pump without demounting the control box.

By pushing and turning a screw driver, Phillips No. 2, the

plunger pushes the shaft in axial direction into the pump,

while it can be turned as well. The force is high enough to

deblock pumps which are seized by lime e.g. if an

UPM3

9

36

Technical description

Loading...

Loading...