15. Performance curves and technical data

Curve conditions

The guidelines below apply to the performance curves:

• Test liquid: airless water.

• The curves apply to a density of 998.21 kg/m

3

and a

liquid temperature of +20 °C.

• All curves show average values and should not be

used as guarantee curves. If a specific minimum

performance is required, individual measurements

must be made.

• The curves apply to a kinematic viscosity of 1.004

mm

2

/s (1.004 cSt).

• The conversion between head H [m] and pressure p

[kPa] has been made for water with a density of 1000

kg/m

3

. For liquids with other densities, for example

hot water, the outlet pressure is proportional to the

density.

• Curves obtained according to EN 16297.

• Pump variants with PWM signal connection are

designed to be speed controlled by an external

system controller. Therefore, EEI and P

L,Avg

of the

different pump heads (pumps without pump

housings) are measured to be in compliance with the

Ecodesign requirements of regulation EC/622/2012

with a reference housing in accordance with EN

16297-3.

• It is not obligatory to show P

L,Avg

but it gives an

indication on the yearly expectable average power

consumption.

• The performance of PWM controlled pumps is

measured with A profile (heating) at eight PWM

values: 5 % (max.), 20 %, 31 %, 41 %, 52 %, 62 %,

73 %, 88 % (min.).

• C profile curves are measured mirrored with 95 %

(max.), 80 %, 69 %, 59 %, 48 %, 38 %, 27 %, 12 %

(min.)

• Maximum curves are limited by speed and power

• Variants with two different minimum curves are

available: minimum curve A (standard) at

approximately 0.1 m and minimum curve J (option) at

approximately 1 m.

• Other curves for different control signals or OEM

housings are available on request.

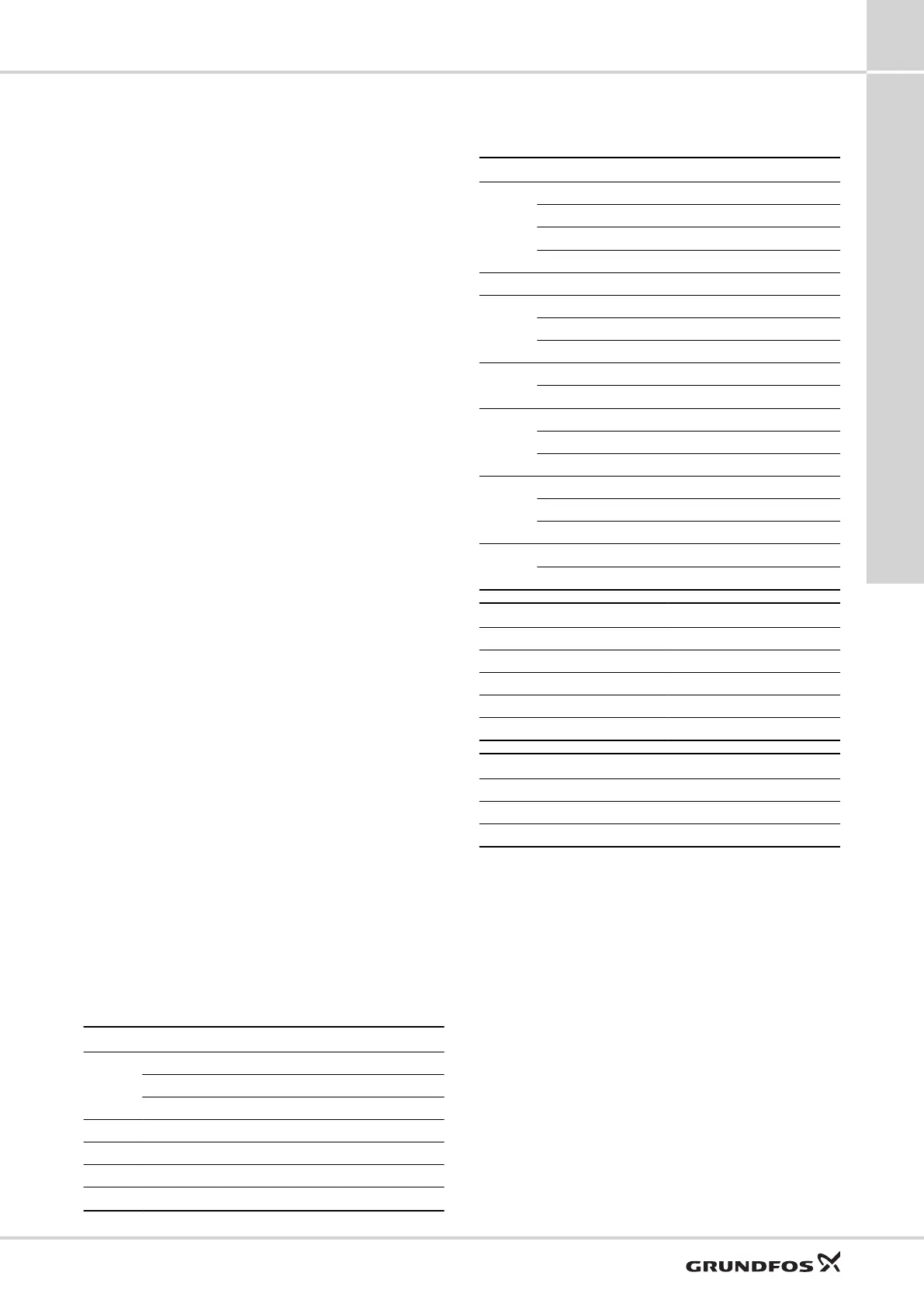

Measured pump head variants

UPM3S

Product mark

P

1

max. nom. [W]

EEI Part 3

PWM

XX-40 GFNHB - ≤ 0.20

XX-50 GFNHB - ≤ 0.20

XX-60 GFNHB 42 ≤ 0.20

LIN XX-60 GFNHB 42 ≤ 0.20

FLEX AS XX-60 GFNHB 42 ≤ 0.20

AUTO XX-60 GFNHB 42 ≤ 0.20

HYBRID XX-60 GFNHB 42 ≤ 0.20

UPM3 Product mark

P

1

max. nom. [W]

EEI Part 3

PWM

XX-50 GFNKB 33 ≤ 0.20

XX-60 GFNKB 39 ≤ 0.20

XX-70 GFNKB 52 ≤ 0.20

XX-75 GFNKB 60 ≤ 0.20

LIN XX-75 GFNKB 60 ≤ 0.20

FLEX AS

XX-50 GFNKB 33 ≤ 0.20

XX-70 GFNKB 52 ≤ 0.20

XX-75 GFNKB 60 ≤ 0.20

AUTO

XX-50 GFNKB 33 ≤ 0.20

XX-70 GFNKB 52 ≤ 0.20

SOLAR

XX-75 GFNKB 45 ≤ 0.20

XX-105 GFNKB 52 ≤ 0.20

XX-145 GFNKB 60 ≤ 0.20

DHW

XX-20 GFNKB 11 ≤ 0.20

XX-50 GFNKB 33 ≤ 0.20

XX-70 GFNKB 52 ≤ 0.20

HYBRID

XX-50 GFNKB 33 ≤ 0.20

XX-70 GFNKB 52 ≤ 0.20

UPM3L Product mark

P

1

max. nom. [W]

EEI Part 3

PWM XX-75 GFNKC 75 ≤ 0.20

LIN XX-75 GFNKC 75 ≤ 0.20

FLEX AS XX-75 GFNKC 75 ≤ 0.20

AUTO XX-70 GFNKC 75 ≤ 0.20

HYBRID XX-70 GFNKC 75 ≤ 0.20

UPMO Product mark

P

1

max. nom. [W]

EEI Part 3

UPMO XX-50 GFNKB 39 ≤ 0.23

UPMO XX-60 GFNKB 60 ≤ 0.23

UPMO XX-70 GFNKC 75 ≤ 0.23

UPM3

15

59

Performance curves and technical data