English (GB)

12

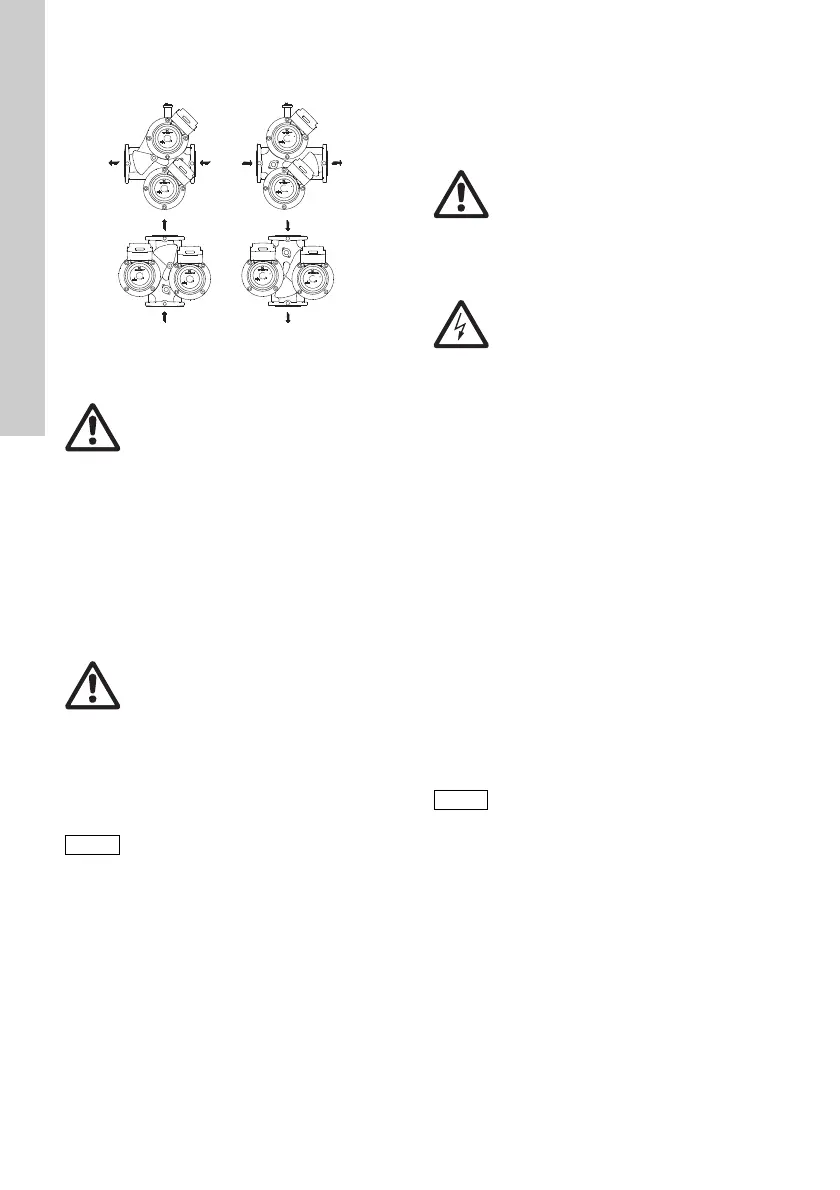

Possible flow directions for twin-head pumps,

see fig. 8.

Fig. 8 Flow directions, twin-head pumps

Change the terminal box position as follows:

1. Remove the four screws holding the pump head.

2. Turn the pump head to the desired position.

3. Refit the four screws and tighten securely.

When changing the terminal box position of twin-

head pumps, it may be necessary to remove the

cable connecting the two terminal boxes. It is

advisable to disconnect the cable from pump 1.

Do not start the pump until the system has been filled

with liquid and vented. Furthermore, the required

minimum inlet pressure must be available at the

pump inlet. See page 330.

To change the nameplate position, ease the outer

edge of the nameplate at the cutout with a

screwdriver, turn the nameplate to the new position,

and push it into place.

5.4 Frost protection

If the pump is not being used during periods of frost,

the necessary steps must be taken to prevent frost

bursts.

6. Electrical connection

The electrical connection must be carried out

according to local regulations.

Check that the supply voltage and frequency

correspond to the values stated on the nameplate.

The thermal overload switch must be adjusted to the

pump full-load current (stated on the pump

nameplate) according to the speed selected.

See fig. 20 at the end of these instructions.

Earthing or neutralisation can be used for protection

against indirect contact. A current- or voltage-

operated earth-leakage circuit breaker can be used

as extra protection.

6.1 Single-head and twin-head pumps with

standard module

The pump must be connected to the power supply

via an external contactor.

The contactor must be connected to the thermal

overload switch incorporated in the pump, terminals

T1 and T2, to protect the pump against overloading

at all three speeds.

Figures 12 and 13 at the end of these instructions

show the possible connections:

• Fig. 12 shows the electrical connections when

using external impulse contacts for start/stop.

• Fig. 13 shows the electrical connections when

using an external changeover contact for start/

stop.

TM02 1399 2701

Warning

Before the screws are removed,

the system must be drained,

or the isolating valves on either side of

the pump must be closed, as the

pumped liquid may be scalding hot and

under high pressure.

Warning

Never make any connections in the

pump terminal box unless the power

supply has been switched off.

When the terminal box position has

been changed, the pump nameplate

must be turned so that the cutout

points downwards. This allows water

from a possible venting to escape.

Warning

Never make any connections in the

pump terminal box unless the power

supply has been switched off.

The pump must be earthed.

The pump must be connected to an

external mains switch with a minimum

contact gap of 3 mm in all poles.

Warning

It must be possible to lock the main

switch in the off position.

Type and requirements as specified in

EN 60204-1, 5.3.2.

If the pump is also protected by a

motor-protective circuit breaker, this

circuit breaker must be set to the

current consumption of the pump at

the selected speed. The motor-

protective circuit breaker setting must

be changed every time the pump speed

is changed. The current consumption

at the individual speeds is stated on

the pump nameplate.

Loading...

Loading...